Glory On mould., Ltd |

|

Class 101 Precision Plastic Mold with Parker Cylinder

| Name | Injection manufacturers professional injection processing custom molded plastic parts |

| Acrylic,PC,PVC,Nylon,PEEK,PU,PA,POM,PE,UPE,PTFE,etc. | |

| Color | White,black,green,nature,blue,yellow,etc |

| Diameter | 5-200mm,or customized |

| Condition | In stock/Made to order |

| Shape | As per your drawing |

| Certification | ISO9001,SGS,Test Report,RoSH |

| Free Sample | Available |

| Shape | Sheet, rod, tube, gear, rack,pulley, guide rail, Plastics fittings,and so on |

| Advantage | One stop procurement |

| Packing | Plastic bags,Cartons,Wooden case,Pallet,Container,ect. |

| Other | 24 hours instant and comfortable customer service. |

| Shipping status notification during delivery. | |

| Regular notification of new styles & hot selling styles. |

Issue Solution Example:

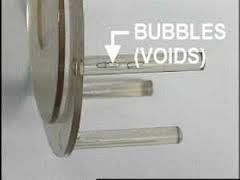

Vacuum Voids

Description: Vacuum voids are pockets of air trapped within or close to the surface of an injection molded prototype.

Causes: Vacuum voids are often caused by uneven solidification between the surface and the inner sections of the prototype. This can be aggravated when the holding pressure is insufficient to condense the molten plastic in the mold (and thereby force out air that would otherwise get trapped). Voids can also develop from a part that is cast from a mold with two halves that are not correctly aligned.

Remedies:

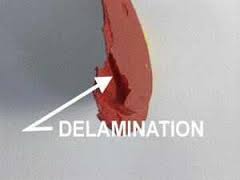

Surface Delamination

Description: Surface delamination is a condition where thin surface layers appear on the part due to a contaminant material. These layers appear like coatings and can usually be peeled off (i.e. “delaminate”).

Causes: Foreign materials that find their way into the molten plastic separate from the finished product because the contaminant and the plastic cannot bond. The fact that they cannot bond not only has an affect on the appearance of the prototype, but also on its strength. The contaminant acts as a localized fault trapped within the plastic. An over-dependence on mold release agents can also cause delamination.

Remedies:

Pipe tool for Auto.

=======================================================================================

Our Main Services:

1. Plastic molds:

Hot runner mold, precision mold, over mold, two-shot mold, unscrewing mold, multi-cavity mold, IML/IMI mold, Stack mold, Die-casting mold, etc.

90% molds exported to North America, South American, Europe and Australia.

2. Injection Molding:

We have rich experience in molding various engineering grade resins:

ABS, PC, PC+GF, PC/ABS, PBT, PA6+GF, PA66+GF, PPS, PU, PP, PE, TPE, TPU, LCP, Ultem, etc.

3. One Stop Services

Based on our strong engineering capability,GOM provide a full turnkey solution for customers bespoke plastic

injection moulding needs inclusive of design, development, mould tooling, production and post moulding support.

• 3D Scanning

• Prototype

• Painting

• Pad-printing

• Silk-Screen Printing

• Hot Stamping

• Plating

• Color Match

• Ultrasonic Welding

• Automation

• Production Line Assembly

• Precision Metal Parts

• Die casting Parts