Zhangjiagang Chiyu Automation Equipment Co., Ltd. |

|

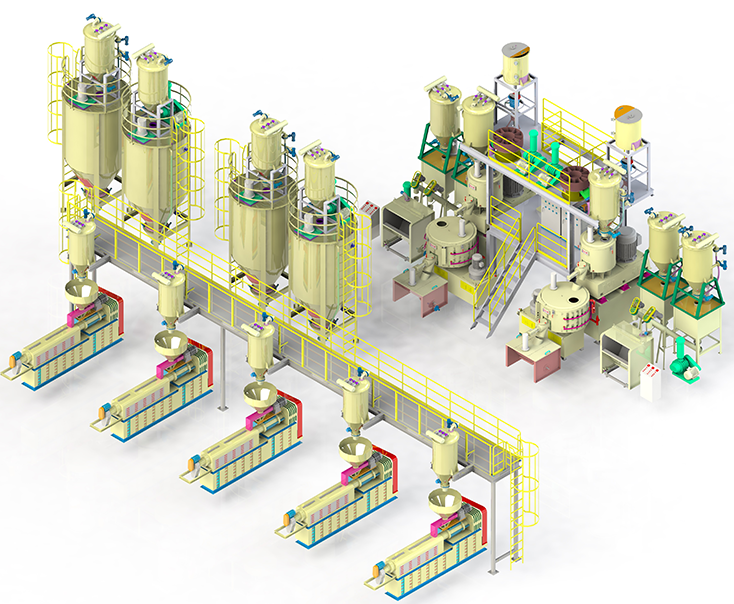

PVC powder feeding systems for plastic mixer or mixing machines

This system includes automatic feeding dosing mixing pneumatic

conveying system, vacuum conveying system, etc. it is suitable for

automatic weighing, mixing and conveying of all powder and chemical

additives to plastic extruder. It has the advantages of high

automation, no dust and high efficiency; Suitable for PVC wall

panel, PVC pipes, Window profiles, PVC cable,Wood composite

Panel(WPC,)SPC floor and other PVC industry customers.

MIXER LOADING SYSTEM

This system is designed for loading of material to the mixer

The system include a dust free bag empty station

A pneumatic conveying system (in negative pressure)

And a control system

Suitable for powder or pellet material

De-bagging for bags (25kg) or jumbo bags (500kg/1000kg)

| NamePneumatic comveying system | Pneumatic comveying system |

| Used for | food,Chemical,rubber |

| Material | Powder,Pellet |

| Capacity | 800-2500Kg/h |

| Powder,Pellet | Siemens 1200+Wincc |

| Inverter | ABB |

Features

Less labor cost

Dust free operation

Specifiction

Bag empty station with exhaust fan and bag filter

Bag filter clean by automatic pressed air purging device

Suction conveying system with blower and hopper loader

Blower type Roots type or Regeneration type

Hoper Loader with the same capacity of mixer

Hoer loader with bag filter for separation of powder and air

Automatic Material Weighing Systems

Features

Automatically Weighs Ingredients via Feeding Device.

Multiple Components/Ingredients in Batch

Batches Introduced Directly Downstream in the Process (Mixer, etc.)

or

Staged for Future Processing

Multiple Formulations

Ensures Batch Integrity (Batch Quality & Consistency) via

Ingredient

Weighment within Programmable Tolerance

RFID and/or Barcode Scanning for Lot Tracking,

Report Generation

Interfaces to Upper Level Systems