Shanghai Shengli Machinery Manufacture Co., Ltd. |

|

LHY Horizontal powder ribbon blender machine

LHY horizontal ribbon mixer is widely used in chemical,

pharmaceuticals, food, and construction line.

It can be used to mix powder with powder, powder with liquid, and

powder with granule.

Under the driven of motor, the double ribbon agitator mix the

material quickly.

The production blending line like:

Feeding machine: manual feeding, crane big bag feeding, screw conveyor feeding, vacuum feeding, bucket elevator etc.

Mixing machine: doubel ribbon blender, single shaft mixer, mixing machine etc.

Filling machine: storage silo, screw conveyor, packing machine, big bag etc.

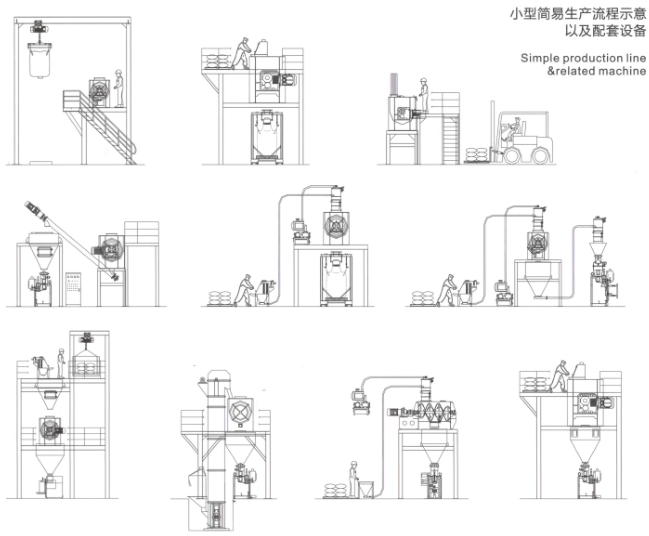

Simple system as dry ingredient bulk production mixing line like:

C1: using crane to hang jumbo bag material and feeding the mixer

C2: mufti-level platform, manual undo the bag, mixing and packing

with a bulk bag packer.

C3: simple mixer frame, feed the mixer manually with the help of a

folk lift.

C 4: using manual feeding platform, after mixing, screw conveyor

send the material to the storage silo, a packer under it.

C5: load the material manually on the ground,use vacuum feed to

transfer material into mixer, after mixing, pack with a bulk-bag

packer.

C6: multi-stage vacuum feeder, store it after mixing, then packing.

C7: multi-level operation platform, elevator sending to material

silo, mixing, storage, and then packing. Tower structure.

C 8: bulket elevator feeding, mixing, storage, and packing.

C9: vacuum feeding, mixing, storage, packing.

C10: Manual feeding, mixing, storage, packing

Double ribbon mixing equipment for food production blending, seasoning blender, spices blender

System is like this:

1. man cut the bag of the raw material or the material has been weighted for one batch usage, and pour into the dust proof dumping funnel which connected with the inlet of the vacuum feeder.

2. the vacuum feeding will suck the material up into the inlet of the mixer

3. the mixer will mix all material for nealy 10mins

4. the discharge valve of the mixer connect with a movable silo by BFM soft nozzle

5. the mixture will fill the bin, and ready for the next packing process

6. one mixer can have several vacuum feeders to increase the feeding speed

7. one mixer can have several movable bins for the different purpose of storage

8. platform is used for add small additives, or do maintenance and cleaning job