Shanghai Shengli Machinery Manufacture Co., Ltd. |

|

Mild Steel Double Shaft Paddle Mixer For Construction Material Plant

Mixer features:

Twin shafts blenders for production line, paint mixer,construction material plant, dry material whole systemWith the most powerful motor, material can be mixed evenly in the shortest time.

It is particularly good at mixing material with big difference in gravity, mesh size, fluidity.

WORKING PRINCIPLE:

Double shaft paddle mixer is a batch mixer with two

counter-rotating shaft that are equipped with ten paddles

they overlap each other following the driven unit, Blades generate

centrifugal force during high speed rotation, spilling the material

to the upper part in the barrel then material falling down( the

vertex of material is in a so called instant non-gravity state).

Driven by the blades material is mixed back and forth: also sheared

and separated by the meshing space between the twin shafts ast and

evenly mixed in the end

When mixing:

1. The horizontal axes make the material move up and down.

2. Rotation at opposition direction of the double axes makes materials exchange from left to right.

3. Paddle stirrers push material at angle 45 to move circularly in the cylinder, and the materials can reach good mixing effect under the movement of radial and axial orientation

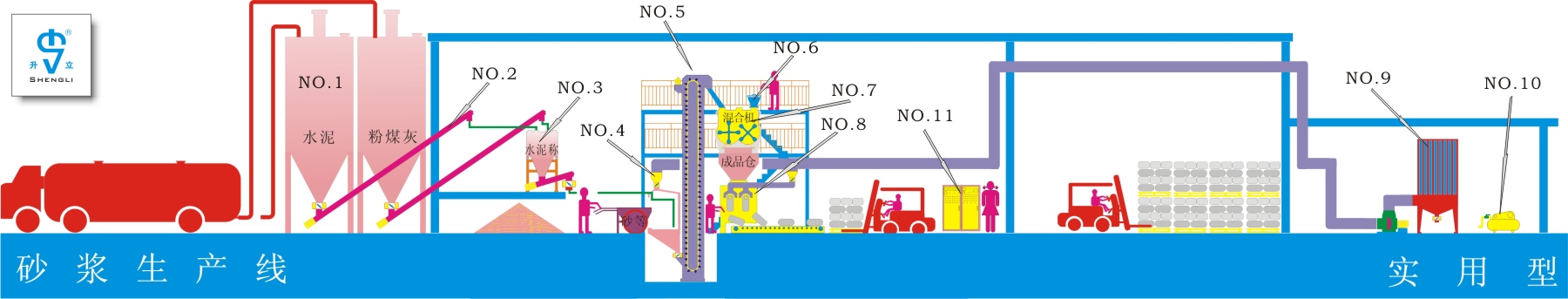

Standard production line in construction material:

with two big raw material silos and weighing system:

1. two raw material like cement store in the big silo outside

2. convey two raw material to the weighing silo by screw conveyor

3. the weighted material goes into the funnel of bucket elevator together with the other material like sand which is poured in by human will be transmitted to the mixer, little additives should be added through a small manual valve in the mixer!

4. all materials mix in the mixer for 5-10minutes

5. the mixture discharge into a silo

6. the worker starts to pack by packing machine, while another batch can go into mixer again

7. The output is 4-6 t/h