Changzhou Xingang Plastic Products Co., Ltd. |

|

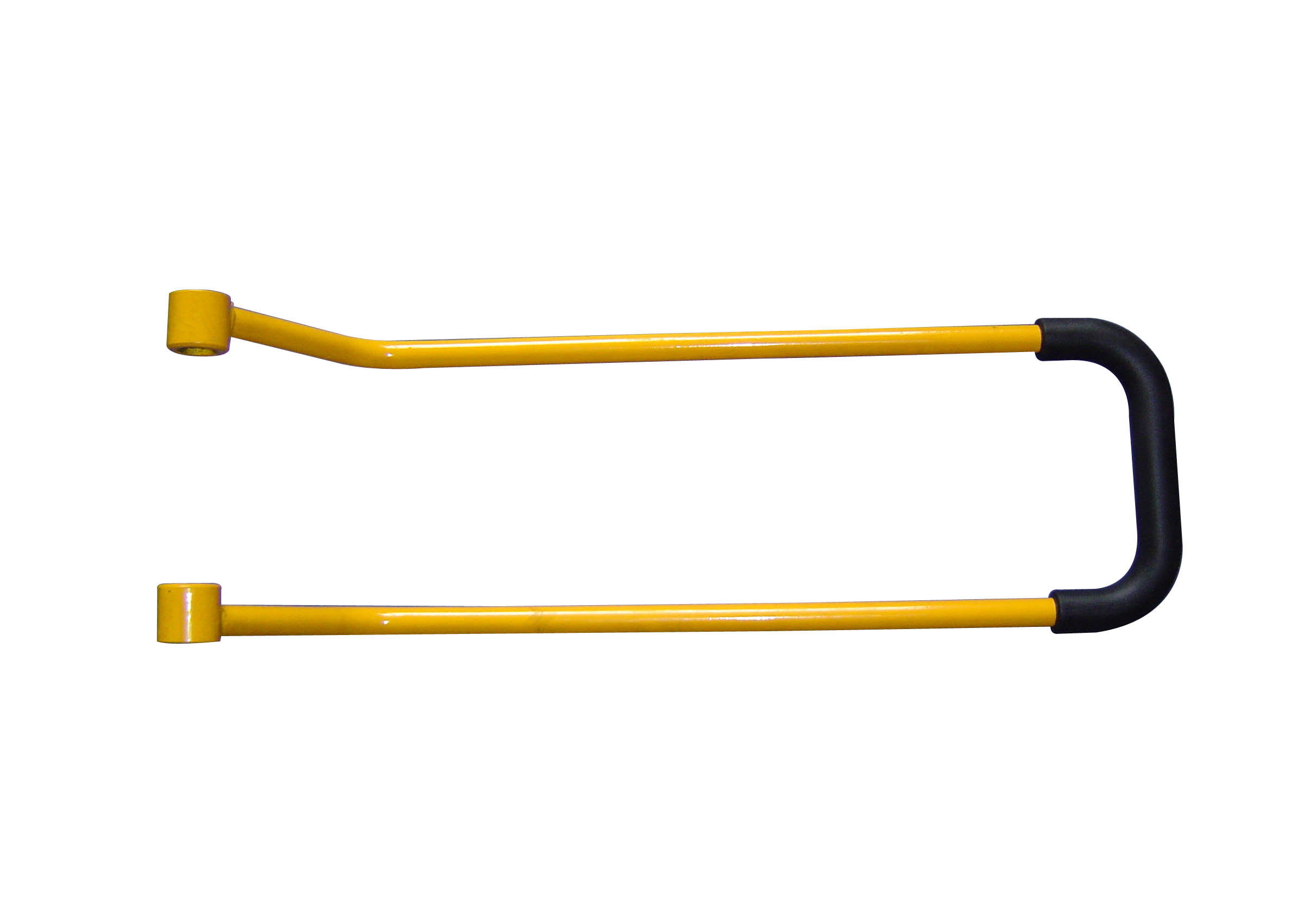

Integral Polyurethane Skin for Hammer rail ![]() Integral skin, also called “self-skinning foam’’ is a microcellular core with a tough,

Integral skin, also called “self-skinning foam’’ is a microcellular core with a tough,

abrasion resistant outer surfaceIntegral skin foams come in a wide range of molded

densities,and they are the perfect solution for a broad variety of applications that require

a soft touch and feel, as well as a highly durable finish.

Fields of application

(Medical technology,Handling units,Access systems,Coating field

Bank and paymentstations,

Consumer electronics,Workpiece carriers)

![]()

Why this foam?

1. Sandwich-style design with high inherent rigidity

2. Extraordinary design flexibility

3. Good thermal and acoustic insulation properties

4. Variable wall sections in a part without sink or distortion

Values not absolute some may be altered.

Properties | Unit | Standard | IHS |

Density | Kg/m³ | ISO/R 1183 / DIN 53479 | 200-250 |

Pulling strength | MPa | ISO/R 527 / DIN 53455 | 19 |

Ultimate elongation | % | ISO/R 527 / DIN 53455 | 6 |

Bending strength (max.) | MPa | ISO 178 / DIN 53452 | 38 |

Bending E-module | MPa | DIN 53457 | 900 |

Impact strength at 23℃ | kJ/㎡ | ISO/R 179 / DIN 53453 | 14 |

Surface hardness | Shore D |

| 67 |

Dimensional stability (HDT) | ℃ | ISO 75-2 | 97 |

![]()

The Technical data is totally provided by SGS test , We accept custom

Design request.

We are very expert in manufacturing customized Integral polyurethane

skin foam parts.

![]()

TIPS

Foams of the same density can vary considerably in strength, depending on the foam

production process.

Different production methods require different chemical formulationsand foam curing

temperatures. General Plastics’ self-skinning

integral skin foams allow items such as aircraft armrest padding to be easily removed

from the mold in the exact shape needed, and already painted or airbrushed in the desired

color.