|

|

[China]

Trade Verify

Address: E 18Floor Fazhan Build No.13 Easy Huayuan Road Chancheng Area Foshan City.

Contact name:ALLSON

BOGEN PUMPS |

|

Verified Suppliers

|

|

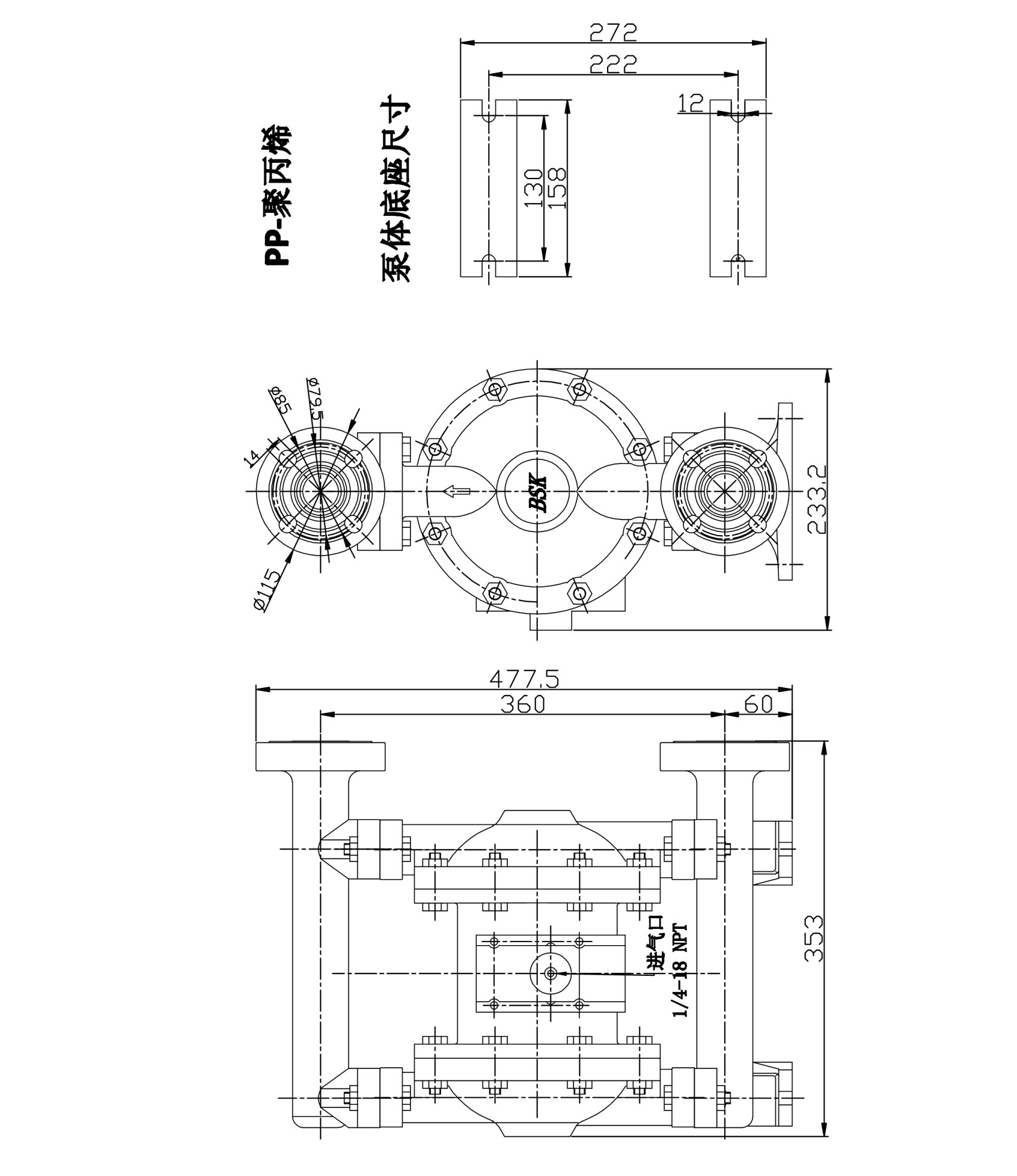

Mining 1.5 Inch Diaphragm Pump / Construction Dual Diaphragm Air Pump

1.5 Inch Diaphragm Pump Description

The 1.5 Inch Diaphragm Pump offers high volume delivery even at low air pressure and a b road range of material compatibility options available.Refer to the model and option chart.The pump is provided with the modularized air motor and fluid section.

The air operated diaphragm pump alternately generates the intake fluid pressure and positive fluid pressure in the fluid chamber by using the pressure difference in the air chamber. The ball valve can ensure the forward flow of fluid.

Pump cycling will begin as air pressure is applied and it will continue to pump and keep up with the demand. It will build and maintain line pres -sure and will stop cycling once maximum line pressure is reached (dis -pensing device closed) and will resume pumping as needed.

1.5 Inch Diaphragm Pump Features

| 1 | Ceramic material for main valve and reversing valve ensures longer life, more stability and working in dirty compressed air ( most occasions, air filter become option). |

| 2 | Without ice with the muffler. Innovative design with the exhaust space of the pump, some of muffler inside, this makes the air outlet smooth.) |

| 3 | Outward parts of the pump are all die casted aluminum and special environment-protected painting, makes the pump with elegant appearance. |

| 4 | Large flow capacity. Innovative design of chamber maximizes the flow capacity. Seamless adjustment with inlet valve, or even close the valve, without damaging the pump. |

| 5 | Low consumption compressed air. Innovative design of the air flow system, minimizes the usage of compressed air to achieve maximum performance. |

| 6 | Light and small size, movable. |

| 7 | Modularization of main valve and air motor. No broken, easy to disassemble and repair. |

1.5 Inch Diaphragm Pump Parameters

| Item | Description | Unit | Reference Figure |

| 1 | Maximum air inlet pressure | Mpa | 0.83 |

| 2 | Maximum flow rate | L/Min | 192 |

| 3 | Maximum lift | M | 70 |

| 4 | Maximum outlet pressure | Mpa | 0.83 |

| 5 | Maximum particle size | mm | 3 |

| 6 | Weight | kg | 12.3 |

| 7 | Noise level | db | <70 |

A 40 X X - X X X - X (model selection)

Form of pipe mouth:A-BSP B-NPT(F) C-Flange

Diaphragm material:9 – Santoprene H – Hytrel T - PTFE/Santoprene

Ball material:9 -Santoprene H – Hytre T – PTFE A - Acetal

Ball seat material:P/K –Polypropylene/Kynoar SS –Stainless Steel

Pump material: SS –Stainless Steel AL –Aluminum Alloy CI- Carbon Steel P/K –Polypropylene/Kynoar

Maximum Applied Temperature Limits (diaphragm / ball / seal material)

Acetal ··············································40°- 150°F (4.4- 65.5°C)

Santoprene········································-40°- 225°F (-40°- 107.2°C) ················································40°- 220°F (4.4°- 104°C) Nitrile················································10°- 180°F (-12°- 82°C) Viton··················································-40°- 350°F (-40°-176.6°C) Hytrel················································-20°-150°F (-12°- 93°C) Kynar·················································10°-200°F (-28.9°- 65.5°C) Polypropylene·····································32°- 175°F (0-79.4°C)

1.5 Inch Diaphragm Pump Flow diagram

1.5 Inch Diaphragm Pump Maintenance