QINGDAO ENNENG MOTOR CO.,LTD. |

|

Verified Suppliers

|

|

Three Phase Low Maintenance Permanent Magnet Motors

Product Parameter

What Is The Permanent Magnet Synchronous Motor?

High-efficiency permanent magnet variable frequency synchronous motors must be used in conjunction with permanent magnet motor frequency converters. The rotor of the motors has a built-in permanent magnet structure, and the special design of different vertical and vertical axis magnetic circuits makes this series of motors have a certain salient pole torque. Therefore, the frequency converter needs to use the maximum torque/current ratio control mode to control the work, so that this series of motors have a higher power factor in the full speed range, a smaller operating current, and lower copper consumption.

The speed of the high-efficiency permanent magnet variable

frequency synchronous motor is synchronized with the stator

rotating magnetic field, there is no slip, and the slip power is

saved, so that the high-efficiency permanent magnet variable

frequency synchronous motor has high efficiency and energy saving

effect in the full speed range obvious.

The high-efficiency permanent magnet frequency conversion

synchronous motors are widely used in injection molding machines,

air compressors, pipe-making equipment, hydraulic machinery, food

machinery, cement pipe-making machines, plastic extruders, wire

drawing machines, and pharmaceutical equipment.

Our company is equipped with a dedicated control cabinet for this

series of products, which can be customized according to user

requirements.

Analysis of the principle of the technical advantages of permanent magnet motor

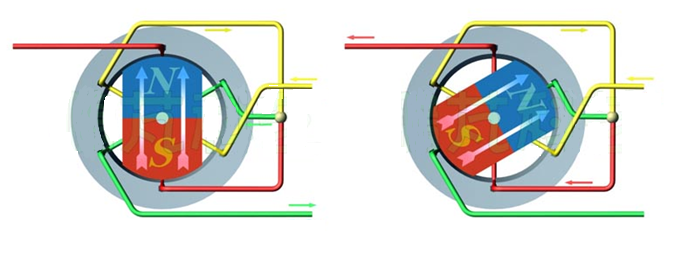

The principle of a permanent magnet synchronous motor is as follows: In the motor's stator winding into the three-phase current, after the pass-in current, it will form a rotating magnetic field for the motor's stator winding. Because the rotor is installed with the permanent magnet, the permanent magnet's magnetic pole is fixed, according to the principle of magnetic poles of the same phase attracting different repulsion, the rotating magnetic field generated in the stator will drive the rotor to rotate, The rotation speed of the rotor is equal to the speed of the rotating pole produced in the stator.

Due to the use of permanent magnets to provide magnetic fields, the rotor process is mature, reliable, and flexible in size, and the design capacity can be as small as tens of watts, up to megawatts. At the same time, by increasing or decreasing the number of pairs of rotor permanent magnets, it is easier to change the number of poles of the motor, which makes the speed range of permanent magnet synchronous motors wider. With multi-pole permanent magnet rotors, the rated speed can be as low as a single digit, which is difficult to achieve by ordinary asynchronous motors.

Especially in the low-speed high-power application environment, the permanent magnet synchronous motor can be directly driven by a multi-pole design at low speed, compared with an ordinary motor plus reducer, the advantages of a permanent magnet synchronous motor can be highlighted.

Differences Between The Permanent Magnet Motor And Asynchronous Motor

01. Rotor Structure

Asynchronous motor: The rotor consists of an iron core and a winding, mainly squirrel-cage and wire-wound rotors. A squirrel-cage rotor is cast with aluminum bars. The magnetic field of the aluminum bar cutting the stator drives the rotor.

PMSM Motor: The permanent magnets are embedded in the rotor magnetic poles, and are driven to rotate by the rotating magnetic field generated in the stator according to the principle of magnetic poles of the same phase attracting different repulsions.

02. Efficiency

Asynchronous motors: Need to absorb current from the grid excitation, resulting in a certain amount of energy loss, motor reactive current, and low power factor.

PMSM Motor: The magnetic field is provided by permanent magnets, the rotor does not need exciting current, and the motor efficiency is improved.

03. Volume And Weight

The use of high-performance permanent magnet materials makes the air gap magnetic field of permanent magnet synchronous motors larger than that of asynchronous motors. The size and weight are reduced compared to asynchronous motors. It will be one or two frame sizes lower than asynchronous motors.

04. Motor Starting Current

Asynchronous motor: It is directly started by power frequency electricity, and the starting current is large, which can reach 5 to 7 times the rated current, which has a great impact on the power grid in an instant. The large starting current causes the leakage resistance voltage drop of the stator winding to increase, and the starting torque is small so heavy-duty starting cannot be achieved. Even if the inverter is used, it can only start within the rated output current range.

PMSM Motor: It is driven by a dedicated controller, which lacks the rated output requirements of the reducer. The actual starting current is small, the current is gradually increased according to the load, and the starting torque is large.

05. Power Factor

Asynchronous motors have a low power factor, they must absorb a large amount of reactive current from the power grid, the large starting current of asynchronous motors will cause a short-term impact on the power grid, and long-term use will cause certain damage to the power grid equipment and transformers. It is necessary to add power compensation units and perform reactive power compensation to ensure the quality of the power grid and increase the cost of equipment use.

There is no induced current in the rotor of the permanent magnet synchronous motor, and the power factor of the motor is high, which improves the quality factor of the power grid and eliminates the need to install a compensator.

06. Maintenance

Asynchronous motor + reducer structure will generate vibration, heat, high failure rate, large lubricant consumption, and high manual maintenance cost; it will cause certain downtime losses.

The three-phase Permanent magnet synchronous motor drives the equipment directly. Because the reducer is eliminated, the motor output speed is low, mechanical noise is low, mechanical vibration is small, and the failure rate is low. The entire drive system is almost maintenance-free.

Application:

Permanent magnet synchronous motors can be combined with frequency converters to form the best open-loop step-less speed control system, which has been widely used for speed control transmission equipment in petrochemical, chemical fiber, textile, machinery, electronics, glass, rubber, packaging, printing, paper making, printing and dyeing, metallurgy and other industries.

Why choose permanent magnet ac motors?

Permanent magnet AC (PMAC) motors offer several advantages over other types of motors, including:

High Efficiency: PMAC motors are highly efficient due to the absence of rotor copper losses and reduced winding losses. They can achieve efficiencies of up to 97%, resulting in significant energy savings.

High Power Density: PMAC motors have a higher power density compared to other motor types, which means they can produce more power per unit of size and weight. This makes them ideal for applications where space is limited.

High Torque Density: PMAC motors have a high torque density, which means they can produce more torque per unit of size and weight. This makes them ideal for applications where high torque is required.

Reduced Maintenance: Since PMAC motors have no brushes, they require less maintenance and have a longer lifespan than other motor types.

Improved Control: PMAC motors have better speed and torque control compared to other motor types, making them ideal for applications where precise control is required.

Environmentally Friendly: PMAC motors are more environmentally friendly than other motor types since they use rare earth metals, which are easier to recycle and produce less waste compared to other motor types.

Overall, the advantages of PMAC motors make them an excellent choice for a wide range of applications, including electric vehicles, industrial machinery, and renewable energy systems.

Maintenance and repair of electric motors

1. The operating environment should always be kept dry, the surface of the motor should be kept clean, and the air inlet should not be obstructed by dust, fibers, etc.

2. When a protection alarm occurs, the cause of the failure should be found out, and the operation can only be put into operation after the failure is eliminated.

3. When the machine is stopped for inspection, the operation can only be carried out after the motor has completely stopped.

4. In order to ensure good lubrication of the motor during operation, the motor should run for about 4000 hours, that is, the grease should be supplemented or replaced (the closed bearing does not need to be replaced during the service life). When the bearing is found to be overheated or the grease has deteriorated during operation, The grease should be replaced in time. When replacing the grease, remove the old grease and clean the oil grooves of the bearings and bearing caps with gasoline. For motors with a speed of 1500r/min and below, refill the bearing grease type for medium and small motors bearing grease No. 2, and fill the inner and outer rings of the bearing About two-thirds of the gap between the bearings; the motor speed of 2500r/min and above is filled with bearing grease type HTHS, which fills about one-half of the gap between the inner and outer rings of the bearing.

5. When the life of the bearing is over, the vibration and noise of the motor will increase obviously. Check that the radial clearance of the bearing reaches the value in the table below, and the bearing should be replaced.

(2) There is a ventilation groove circuit inside the rotor to reduce the temperature rise of the rotor:

If the temperature of the rotor is too high, the permanent magnet will cause irreversible loss of magnetism. In the structural design, the internal ventilation circuit of the rotor can be designed to directly cool the magnetic steel. Not only reduces the temperature of the magnetic steel but also improves the efficiency.