QINGDAO ENNENG MOTOR CO.,LTD. |

|

Verified Suppliers

|

|

Long Lifespan Variable Frequency Heavy Duty Permanent Magnet Electric Motor

What Is The Permanent Magnet Synchronous Motor?

The PERMANENT MAGNET SYNCHRONOUS MOTOR is mainly composed of the stator, rotor, chassis, front-rear cover, bearings, etc. The structure of the stator is basically the same as that of ordinary asynchronous motors, and the main difference between the permanent magnet synchronous motor and other kinds of motors is its rotor.

The permanent magnet material with pre-magnetized (magnetic charged) magnetic on the surface or inside the permanent magnet of the motor, provides the necessary air gap magnetic field for the motor. This rotor structure can effectively reduce the motor volume, reduce loss and improve efficiency.

Analysis of the principle of the technical advantages of permanent magnet motor

The principle of a permanent magnet synchronous motor is as follows: In the motor's stator winding into the three-phase current, after the pass-in current, it will form a rotating magnetic field for the motor's stator winding. Because the rotor is installed with the permanent magnet, the permanent magnet's magnetic pole is fixed, according to the principle of magnetic poles of the same phase attracting different repulsion, the rotating magnetic field generated in the stator will drive the rotor to rotate, The rotation speed of the rotor is equal to the speed of the rotating pole produced in the stator.

Due to the use of permanent magnets to provide magnetic fields, the rotor process is mature, reliable, and flexible in size, and the design capacity can be as small as tens of watts, up to megawatts. At the same time, by increasing or decreasing the number of pairs of rotor permanent magnets, it is easier to change the number of poles of the motor, which makes the speed range of permanent magnet synchronous motors wider. With multi-pole permanent magnet rotors, the rated speed can be as low as a single digit, which is difficult to achieve by ordinary asynchronous motors.

Especially in the low-speed high-power application environment, the permanent magnet synchronous motor can be directly driven by a multi-pole design at low speed, compared with an ordinary motor plus reducer, the advantages of a permanent magnet synchronous motor can be highlighted.

Working of Permanent Magnet Synchronous Motor:

The working of the permanent magnet synchronous motor is very simple, fast, and effective when compared to conventional motors. The working of PMSM depends on the rotating magnetic field of the stator and the constant magnetic field of the rotor. The permanent magnets are used as the rotor to create constant magnetic flux and operate and lock at synchronous speed. These types of motors are similar to brushless DC motors.

The phasor groups are formed by joining the windings of the stator with one another. These phasor groups are joined together to form different connections like a star, Delta, and double and single phases. To reduce harmonic voltages, the windings should be wound shortly with each other.

When the 3-phase AC supply is given to the stator, it creates a rotating magnetic field and the constant magnetic field is induced due to the permanent magnet of the rotor. This rotor operates in synchronism with the synchronous speed. The whole working of the PMSM depends on the air gap between the stator and rotor with no load.

If the air gap is large, then the windage losses of the motor will be reduced. The field poles created by the permanent magnet are salient. The permanent magnet synchronous motors are not self-starting motors. So, it is necessary to control the variable frequency of the stator electronically.

Application of rare earth permanent magnet motor

The advantages of the rare earth magnets permanent magnet motors are many and varied, making it an ideal choice for a wide range of applications. Its low rpm and high torque output make it perfect for direct drive applications such as compressors, pumps, and fans. Additionally, its low noise output means that it is ideal for use in environments where noise reduction is a priority. Finally, its low maintenance requirements make it a cost-effective option over the long term.

Advantages Of Rare-earth Permanent Magnet Motors

High efficiency: The efficiency curve of the asynchronous motor generally falls faster under 60% of the rated load, and the efficiency is very low at light load. The efficiency curve of the rare earth permanent magnet motor is high and flat, and it is in the high-efficiency area at 20%~120% of the rated load.

High power factor: The measured value of the power factor of the rare earth permanent magnet synchronous motor is close to the limit value of 1.0. The power factor curve is as high and flat as the efficiency curve. The power factor is high. Low-voltage reactive power compensation is not required and the power distribution system capacity is fully utilized.

Stator current is small: The rotor has no excitation current, the reactive power is reduced, and the stator current is significantly reduced. Compared with the asynchronous motor of the same capacity, the stator current value can be reduced by 30% to 50%. At the same time, because the stator current is greatly reduced, the motor temperature rise is reduced, and the bearing grease and bearing life are extended.

High out-of-step torque and pull-in torque: Rare earth permanent magnet synchronous motors have higher out-of-step torque and pull-in torque, which makes the motor have higher load capacity and can be smoothly pulled into synchronization.

Disadvantages Of Rare-earth Permanent Magnet Motors

High cost: Compared with the asynchronous motor of the same specification, the air gap between the stator and the rotor is smaller, and the processing accuracy of each component is high; the rotor structure is more complicated and the price of rare earth magnetic steel material is high; therefore, the motor manufacturing cost is high, which is common for asynchronous motors About 2 times.

Large impact at full power start: When starting at full pressure, the synchronous speed can be drawn in a very short time. The mechanical shock is large. The starting current is more than 10 times the rated current. The impact on the power supply system is large, requiring a large capacity of the power supply system.

Rare-earth magnet steel is easy to demagnetize: When the permanent magnet material is subjected to vibration, high temperature, and overload current, its magnetic permeability may decrease, or the demagnetization phenomenon occurs, which reduces the performance of the permanent magnet motor.

PM motor structures

PM motor structures can be separated into two categories: interior

and surface. Each category has its subset of categories. A surface

PM motor can have its magnets on or inset into the surface of the

rotor, to increase the robustness of the design. An interior

permanent magnet motor positioning and design can vary widely. The

IPM motor’s magnets can be inset as a large block or staggered as

they come closer to the core. Another method is to have them

embedded in a spoke pattern.

PM motor inductance variation with load

Only so much flux can be linked to a piece of iron to generate

torque. Eventually, the iron will saturate and no longer allow flux

to link. The result is a reduction in the inductance of the path

taken by a flux field. In a PM machine, the d-axis and q-axis

inductance values will reduce with increases in the load current.

The d and q-axis inductances of an SPM motor are nearly identical. Because the magnet is outside of the rotor, the inductance of the q-axis will drop at the same rate as the d-axis inductance. However, the inductance of an IPM motor will reduce differently. Again, the d-axis inductance is naturally lower because the magnet is in the flux path and does not generate an inductive property. Therefore, there is less iron to saturate in the d-axis, which results in a significantly lower reduction in flux with respect to the q-axis.

Flux weakening/intensifying of PM motors

Flux in a permanent magnet motor is generated by the magnets. The

flux field follows a certain path, which can be boosted or opposed.

Boosting or intensifying the flux field will allow the motor to

temporarily increase torque production. Opposing the flux field

will negate the existing magnet field of the motor. The reduced

magnet field will limit torque production, but reduce the back-emf

voltage. The reduced back-emf voltage frees up the voltage to push

the motor to operate at higher output speeds. Both types of

operation require additional motor current. The direction of the

motor current across the d-axis, provided by the motor controller,

determines the desired effect.

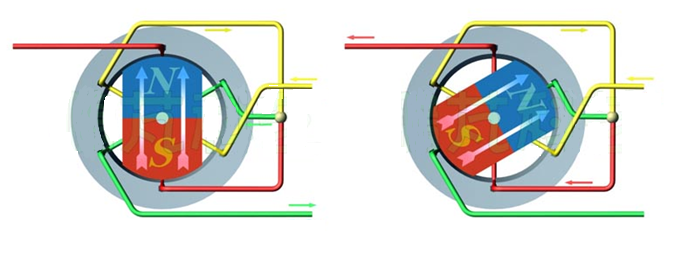

IPM VS SPM

A PM motor can be separated into two main categories: surface permanent magnet motors (SPM) and interior permanent magnet motors (IPM) Neither motor design type contains rotor bars. Both types generate magnetic flux by the permanent magnets affixed to or inside of the rotor.

SPM motors have magnets affixed to the exterior of the rotor surface. Because of this mechanical mounting, their mechanical strength is weaker than that of IPM motors. The weakened mechanical strength limits the motor’s maximum safe mechanical speed. In addition, these motors exhibit very limited magnetic saliency (Ld ≈ Lq). Inductance values measured at the rotor terminals are consistent regardless of the rotor position. Because of the near unity saliency ratio, SPM motor designs rely significantly, if not completely, on the magnetic torque component to produce torque.

IPM motors have a permanent magnet embedded into the rotor itself. Unlike their SPM counterparts, the location of the permanent magnets makes IPM motors very mechanically sound, and suitable for operating at very high speeds. These motors also are defined by their relatively high magnetic saliency ratio (Lq > Ld). Due to their magnetic saliency, an IPM motor has the ability to generate torque by taking advantage of both the magnetic and reluctance torque components of the motor.

EMF and Torque Equation

In a synchronous machine, the average EMF induced per phase is called dynamic induces EMF in a synchronous motor, the flux cut by each conductor per revolution is Pϕ Weber

Then the time taken to complete one revolution is 60/N sec

The average EMF induced per conductor can be calculated by using

( PϕN / 60 ) x Zph = ( PϕN / 60 ) x 2Tph

Where Tph = Zph / 2

Therefore, the average EMF per phase is,

= 4 x ϕ x Tph x PN/120 = 4ϕfTph

Where Tph = no. Of turns connected in series per phase

ϕ = flux/pole in Weber

P= no. Of poles

F= frequency in Hz

Zph= no. Of conductors connected in series per phase. = Zph/3

The EMF equation depends on the coils and the conductors on the stator. For this motor, the distribution factor Kd and pitch factor Kp is also considered.

Hence, E = 4 x ϕ x f x Tph xKd x Kp

The torque equation of a permanent magnet synchronous motor is given as,

T = (3 x Eph x Iph x sinβ) / ωm

Permanent magnet motors are advanced motors similar to both induction motors and servo motors in design. They are composed of a stator – the outside housing – and a rotor – the moving component connected to the output shaft of the motor. Much like other AC motors, the permanent magnet motor harnesses the physics of electromagnetism to generate torque, and they do this by using permanent magnets (usually rare earth magnets) embedded in their rotor. This design deviates from most other electric motors, where the rotor either generates its own magnetic field via induction or a through the use of a DC power source or is simply composed of a ferromagnetic metal. The magnets in a permanent magnet motor, when properly arranged in relation to the stator, can provide speeds equal to the excitation current frequency, and so are considered a synchronous motor. These motors must be paired with an electronic component that smooths out the torque of this motor, and this is why these machines have only recently hit their stride as a viable design.

Why use permanent magnet motors?

Permanent Magnet Synchronous Motors (PMSM) are advanced AC electric motors consisting of a stator and a rotor that is connected to the output shaft. Permanent magnet motors typically use Neodymium magnets which are embedded in the rotor to create torque garnered by electromagnetism. This type of motor differs from most other electric motors, whereby the rotor generates its own magnetic field through induction, or where the field currents are transferred to the rotor by brushes and slip rings. PMSM motors are an excellent choice for a range of motion control applications.

The development trend of rare earth permanent magnet motors

Rare earth permanent magnet motors are developing towards high power (high speed, high torque), high functionality and miniaturization, and are constantly expanding new motor varieties and application fields, and the application prospects are very optimistic. In order to meet the needs, the design and manufacturing process of rare earth permanent magnet motors still need to be continuously innovated, the electromagnetic structure will be more complex, the calculation structure will be more accurate, and the manufacturing process will be more advanced and applicable.

Application of rare earth permanent magnet motor

Due to the superiority of rare earth permanent magnet motors, their applications are becoming more and more extensive. The main application areas are as follows:

Focus on the high efficiency and energy saving of rare earth permanent magnet motors. The main application objects are large power consumers, such as rare earth permanent magnet synchronous motors for textile and chemical fiber industries, rare earth permanent magnet synchronous motors for various mining and transportation machinery used in oil fields and coal mines, and rare earth permanent magnet synchronous motors for driving various pumps and fans.