Nanjing Tenkai Heat Exchanger Co.,Ltd |

|

Verified Suppliers

|

|

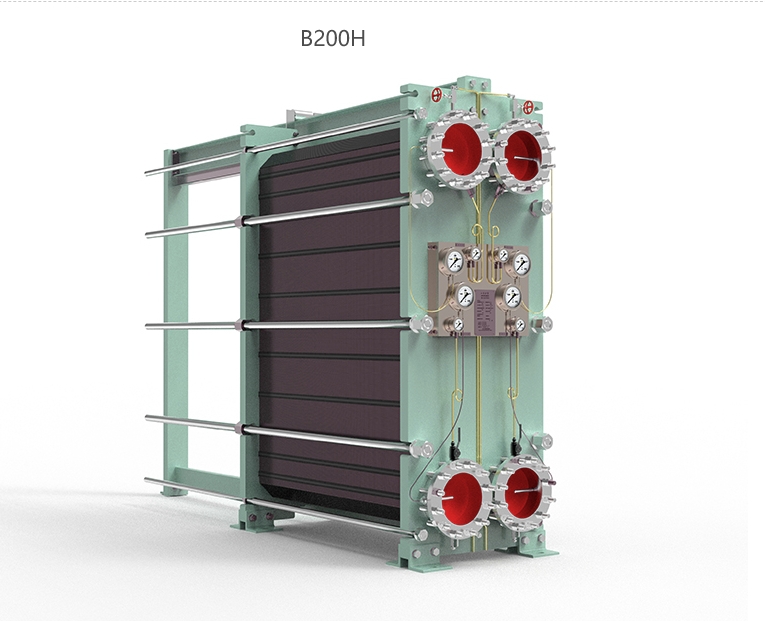

The Brazed Plate Heat Exchanger is a pinnacle of thermal technology, offering an exceptional solution for heating and cooling applications across a multitude of industries. This state-of-the-art frame and plate heat exchanger is designed with efficiency, durability, and performance in mind, catering to the needs of customers who demand reliability and effectiveness in their thermal exchange processes.

Constructed with the highest quality materials, the Brazed Plate Heat Exchanger boasts a robust design that is capable of withstanding maximum pressures up to 4.5Mpa. This makes it an ideal choice for high-pressure operations, providing a secure and stable performance under the most demanding conditions. Whether it is used in HVAC systems, refrigeration, or industrial processes, this heat exchanger is engineered to deliver unparalleled efficiency.

The Brazed Plate Heat Exchanger is also designed to accommodate a wide range of temperatures, with a design temperature capability ranging from -196°C to 225°C. Such an extensive temperature range ensures that the heat exchanger can be employed in various applications, from cryogenic temperatures to high-temperature operations, without compromising its integrity or performance. This versatility is essential for industries that operate across different temperature spectrums.

Quality and compliance are at the forefront of the Brazed Plate Heat Exchanger's design. Proudly holding the ISO9001 certification, this heat exchanger meets the rigorous quality management standards set by the International Organization for Standardization. This certification is a testament to the premium quality, safety, and reliability of the product, giving customers the confidence they need when integrating it into their systems.

One of the critical features of the Brazed Plate Heat Exchanger is the option for braze material. Customers can choose between copper and stainless steel, depending on their specific needs and the nature of the fluids being processed. Copper brazing is renowned for its excellent thermal conductivity and resistance to corrosion, making it ideal for standard applications. Stainless steel, on the other hand, offers superior durability and is well-suited for situations where corrosion or chemical reactions are a concern.

The heat transfer efficiency of the Brazed Plate Heat Exchanger is second to none, with available heat transfer areas ranging from 0.03 to 1.2 m² per piece. This range allows for precise customization according to the specific requirements of the application, ensuring that the heat exchanger operates at optimal efficiency. The large surface area of the plates facilitates the transfer of heat, making the process quicker and more energy-efficient.

As a frame and plate heat exchanger, this product is characterized by its compact structure that consists of multiple, thin, corrugated plates brazed together at the edges. The plates form channels through which the working fluids can flow and exchange heat. The unique corrugated design of the plates creates turbulent flows, which enhance the heat transfer coefficient and reduce the buildup of deposits, thereby maintaining the heat exchanger's efficiency over time.

In conclusion, the Brazed Plate Heat Exchanger is an exceptional frame and plate heat exchanger that combines durability, versatility, and high performance. With its wide temperature range, high-pressure tolerance, adherence to ISO9001 standards, customizable braze materials, and efficient heat transfer properties, it stands as an industry-leading solution for all your heating and cooling needs. Whether for residential, commercial, or industrial applications, this heat exchanger is engineered to provide the highest levels of thermal efficiency and reliability.

| Parameter | Specification |

|---|---|

| Connections | Male Thread, Thread, SAE Flange, Soldering |

| Heat Transfer Area | 0.03-1.2 M²/pcs |

| Specification | Customized |

| Warranty | 1 Years |

| Design Temperature | -196 To 225 C |

| Certifications | ISO9001 |

| Max Pressure | 4.5Mpa |

| Braze Material | Copper, Stainless Steel |

| Plate Design | Chevron |

| Flow Rate | 8-300 M³/h |

The Tenkai Brazed Plate Heat Exchanger, originating from China, is a high-quality device that has earned the ISO9001 certification. This heat exchanger is ideal for a variety of applications and scenarios, thanks to its robust design and versatility. With a minimum order quantity of just one set and competitive pricing, it offers a cost-effective solution for many thermal management needs. The product is carefully packaged in wooden crates to ensure safe delivery within two weeks from the order date.

Adaptable to a broad range of uses, the Tenkai Brazed Plate Heat Exchanger is perfect for systems requiring a Full Welded Plate Heat Exchanger. The innovative design, which includes a Chevron plate pattern, optimizes heat transfer efficiency and minimizes fouling, making it suitable for heavy-duty operations. The exchanger's braze materials, which include copper and stainless steel options, cater to various industry requirements, ensuring compatibility with many different fluids and operating conditions.

With a design temperature range from -196 to 225 degrees Celsius and a flow rate capacity of 8-300 m³/h, the Tenkai Brazed Plate Heat Exchanger is capable of handling extreme thermal environments while maintaining efficiency and reliability. This makes it an excellent choice for industries requiring a Frame And Plate Heat Exchanger, where durability and performance are paramount. The heat exchanger's compact size and full welded structure provide a long-lasting solution that can withstand rigorous operational demands.

Tenkai's commitment to quality is evident in the product's warranty of 1 year, ensuring customer satisfaction and performance assurance. The payment terms are flexible, with options like T/T, L/C, and D/P available to cater to different customer preferences. The company also boasts a strong supply ability, capable of delivering 120-160 pieces per day, thus meeting the demands of both small-scale and large-scale projects. Whether for industrial, commercial, or residential applications, the Tenkai Brazed Plate Heat Exchanger stands out as a reliable and efficient choice for those in need of a high-performance Frame And Plate Heat Exchanger.

Brand Name: Tenkai

Place of Origin: China

Certification: ISO9001

Minimum Order Quantity: 1 set

Price: Competitive

Packaging Details: Wooden Package

Delivery Time: Within two weeks

Payment Terms: T/T, L/C, D/P

Supply Ability: 100-110pcs/day

Flow Rate: 8-300 M³/h

Connections: Male Thread, Thread, SAE Flange, Soldering

Warranty: 1 Years

Specification: Customized

Max Pressure: 4.5Mpa

Product Description: The Tenkai Brazed Plate Heat Exchanger, a versatile and efficient solution, is designed for a wide range of applications. Our Fusion Bonded Plate Heat Exchanger offers high durability and performance, ensuring a reliable heat transfer process. For larger applications, our Frame And Plate Heat Exchanger can be tailored to meet your specific needs, providing exceptional quality and customized specifications for optimal results.

The Brazed Plate Heat Exchanger is designed to provide efficient heat transfer in a compact, durable, and maintenance-free design. Our technical support services include a comprehensive guide for installation, operation, and troubleshooting to ensure your heat exchanger operates at peak performance. We offer detailed documentation on material specifications, flow dynamics, and temperature parameters tailored to your specific application needs.

For maintenance and service inquiries, our support team provides guidance on routine inspection and cleaning procedures to maintain optimal efficiency and prolong the life of your heat exchanger. In the event of a technical issue, our troubleshooting support is available to help diagnose and resolve problems quickly and effectively. We also provide recommendations on spare parts and upgrade options to enhance the performance of your heat exchanger over time.

Our commitment to quality service ensures that you receive the necessary support to keep your Brazed Plate Heat Exchanger functioning reliably. Our team is dedicated to offering professional advice and assistance to help you maximize the benefits of our advanced heat exchanger technology.

The Brazed Plate Heat Exchanger is precision-engineered and requires careful handling to ensure its integrity and performance. Our packaging is designed to protect the product from damage during transit. Each heat exchanger is encased in a robust, form-fitting foam padding that conforms to its shape, providing cushioning and shock absorption.

To further safeguard the heat exchanger, the padded unit is placed within a sturdy, corrugated cardboard box that is sized appropriately to prevent excessive movement. Reinforced corners and edges offer additional protection against impacts and compression.

For shipping, the boxed heat exchanger is secured on a wooden pallet, allowing for ease of handling by forklifts and pallet jacks. The entire package is then wrapped in a durable, stretchable plastic wrap, ensuring that the box remains stable and securely attached to the pallet throughout the shipping process.

We clearly label each package with the necessary shipping information, handling instructions, and any cautionary warnings to ensure that the product is transported safely and arrives in optimal condition. Our carriers are selected for their reliability and commitment to handling goods with care.