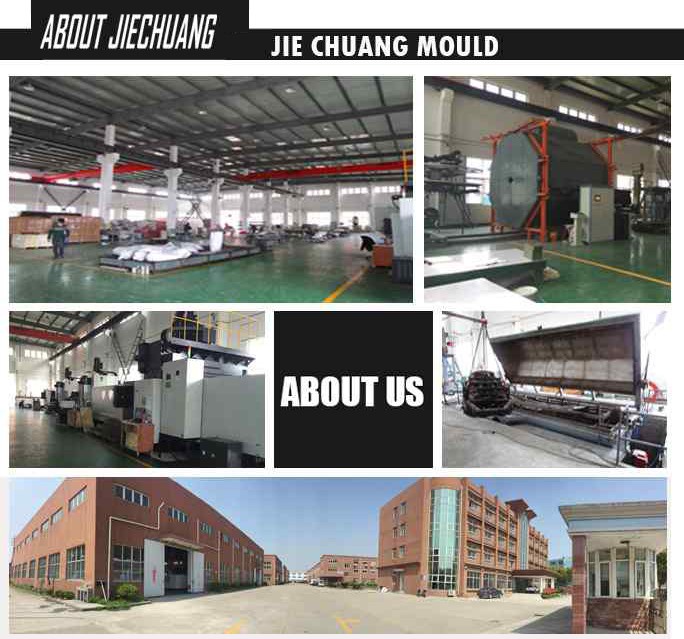

Shanghai Jiechuang Mold Manufacturing Co., Ltd. |

|

| ||||||||||||||||

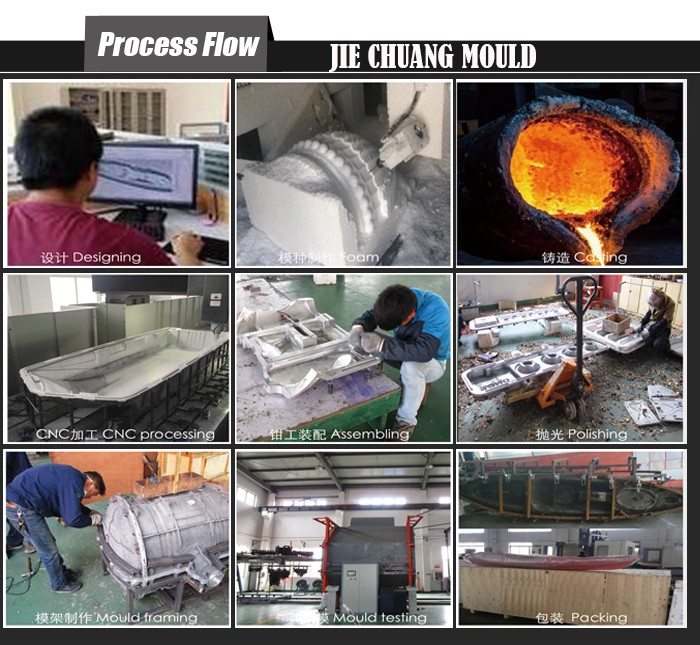

Rotational moulding, known also as rotomolding or rotocasting, is a process for manufacturing hollow plastic products. For certain types of liquid vinyls, the term slush molding is also used. Rotational molding has particular advantages in terms of relatively low levels of residual stresses and inexpensive molds. Rotational molding also has few competitors for the production of large (> 2 m3) hollow objects in one piece. Rotational molding is best known for the manufacture of tanks but it can also be used to make complex medical products, toys, leisure craft, and highly aesthetic point-of-sale products.

Roto Advantage

RFQ

A: We are factory.

A: Generally it is 35 days after confirming drawing and receive advanced payment.

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

A: 50% advanced payment, the balance before shippment.