Suzhou Middle Tech Industry Co., Ltd |

|

Plastic PVC roofing junction box extrusion line

INTRODUCTION:

Through market combination and continuous research innovation, Midtech pleased to provide

energy saving (15% down),

high standard (Bimetallic & PLC Intelligence),

reliable quality (vertical gearbox by SKF bearing)

Excellent screw design (suitable for high percent CaCo3 and wood

powder)

extruder and whole set extrusion and production line

Technical data

| Model/data | Max width | Extruder model | Motor power | Max capacity |

| MT180 | 180mm | MT51/105 | 22kw | 120kg/h |

| MT240 | 300mm | MT65/132 | 37kw | 260kg/h |

| MT600 | 600mm | MT80/156 | 55kw | 400kg/h |

| MT800 | 800mm | MT92/188 | 90/100kw | 650kg/h |

Work flow and detailed configuration:

| Feeder | • To feed material into extruder; |

| Extruder | •World famous brand electrical component: Siemens, Schneider, ABB

etc; • High torque gearbox with adopts NSK/SKF bearing; • Siemens/WEG original motor achieved global after service; • Bimetallic screw and barrel; • Intelligent PLC controlling system with human-friendly interface. |

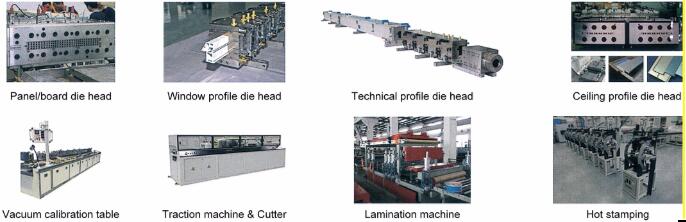

| Die head | • 3Cr13/3Cr17 material • Complete set include extrusion die head, calibrator and cooling tank • Adopt to single, co-extrusion, foam imitation marble profile |

| Calibration table | • Include full set of vacuum and water pump • Width: 240mm • Length: 6000mm • Independent operation panel for easy operation |

| Haul off | • Upper/lower caterpillar driven separately and speed control by

inverter • Fast change type pads for easy operation • Install plate is adopts aluminum material |

| Cutter | • Lifting saw cutter with adopts double station dust collection

system •Synchronous drivingby air cylinder or servo motor control |

| Stacker | • Stainless steel304 as touching material • Discharge driving by air cylinder |

| Hot stamping machine | • Decorative pattern and film protection of product surface |

Why choose us

♦ Specified screw design and material application for high

percentage CaCO3

♦ Intelligent PLC controlling system with human-friendly interface

make the operation easily.

♦ Turn-key solution provided include plant layout and design,

formula, production support.

♦ Super extend sales guarantee for all our machines: 18 months

since the machine left supplier plant.

♦ Competitive price for all our machines to meet customer demand.

♦ World wide after services center: Hungary, Spain, Nigeria, UAE,

Brasil, Peru...