Shaanxi Peter International Trade Co., Ltd. |

|

Verified Suppliers

|

|

DIN 2631 Carbon Steel and Stainless Steel Weld Neck Flanges WNRF PN6 for Industrial Purposes

Introduction:

We are Shaanxi Peter International Trade Co., Ltd., a reputable and well-established company of rich experience in the industry. As your reliable supplier, we have been providing high-quality DIN WELD NECK FLANGES for more than 20 years in the industry.

DIN weld neck flanges are a type of pipe flange that is designed to be butt-welded to the end of a pipe. They have a long tapered hub that gradually merges with the pipe, providing reinforcement and reducing stress concentrations. The flange is then bolted to another weld neck flange or a compatible flange using bolts or studs.

DIN standards are widely used in Europe, particularly in Germany, and DIN weld neck flanges conform to the specific dimensional and technical requirements set by DIN standards. These flanges are available in various materials such as carbon steel, stainless steel, and alloy steel, allowing them to be used in a wide range of applications in industries such as oil and gas, petrochemical, power generation, and more.

Description of DIN Weld Neck Flanges:

Weld neck flanges are widely considered the most popular type of flange due to their unique design featuring a neck extension with a weld bevel at the end. These flanges are specifically engineered to be butt-welded directly to pipes, resulting in a superior and seamless connection. In larger sizes and higher pressure classes, the weld neck flange is predominantly used as the preferred flange connection.

In fact, if there were only one type of flange available in modern applications, the weld neck flange would undoubtedly be the top choice. Its design and functionality make it highly desirable for a wide range of industrial applications. The weld neck flange's ability to provide a reliable, leak-free, and durable connection between pipes is unparalleled.

The weld neck flange's weld bevel and neck extension allow for a smooth and natural transition from the pipe to the flange. This seamless connection minimizes turbulence and pressure drop within the piping system, making it ideal for applications where efficiency and flow performance are critical.

Furthermore, the weld neck flange's design offers excellent structural integrity and helps distribute mechanical stresses evenly, making it suitable for high-pressure and high-temperature environments. The weld neck flange's robust construction ensures long-lasting performance and minimizes the risk of leakage or failure.

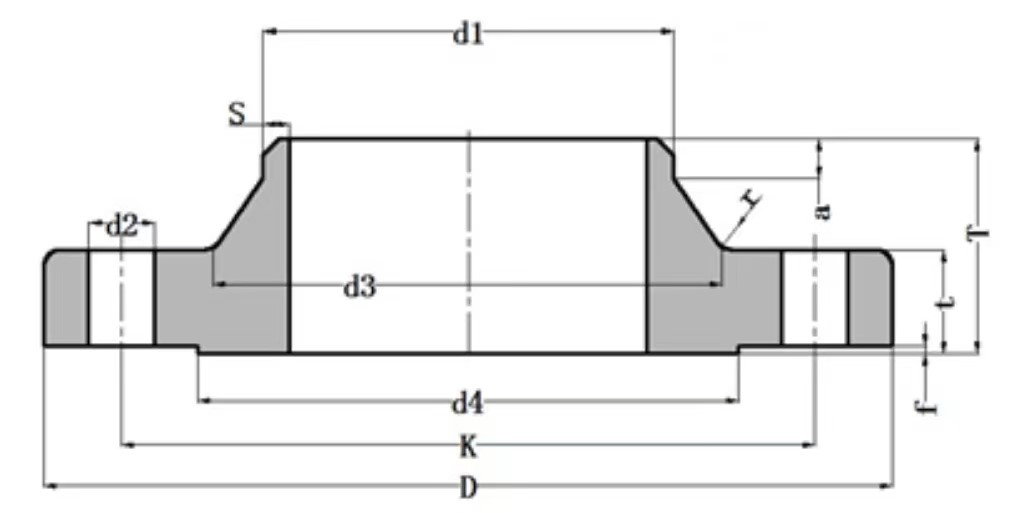

DIN 2631 Weld Neck Flange Dimensions:

| DIN2631 Welding Neck Flange PN6 | |||||||||||||||

| DN | d1 | D | t | k | T | d3 | S | r | a | d4 | f | No. of holes | d2 | Weight (KG) | |

| ISO | DIN | ||||||||||||||

| 10 | - | 14 | 75 | 12 | 50 | 28 | 22 | 1.8 | 4 | 6 | 35 | 2 | 4 | 11 | 0.3 |

| 17.2 | - | 75 | 12 | 50 | 28 | 26 | 1.8 | 4 | 6 | 35 | 2 | 4 | 11 | 0.3 | |

| 15 | - | 20 | 80 | 12 | 55 | 30 | 28 | 2 | 4 | 6 | 40 | 2 | 4 | 11 | 0.4 |

| 21.3 | - | 80 | 12 | 55 | 30 | 30 | 2 | 4 | 6 | 40 | 2 | 4 | 11 | 0.4 | |

| 20 | - | 25 | 90 | 14 | 65 | 32 | 35 | 2.3 | 4 | 6 | 50 | 2 | 4 | 11 | 0.6 |

| 26.9 | - | 90 | 14 | 65 | 32 | 38 | 2.3 | 4 | 6 | 50 | 2 | 4 | 11 | 0.6 | |

| 25 | - | 30 | 100 | 14 | 75 | 35 | 40 | 2.6 | 4 | 6 | 60 | 2 | 4 | 11 | 0.8 |

| 33.7 | - | 100 | 14 | 75 | 35 | 42 | 2.6 | 4 | 6 | 60 | 2 | 4 | 11 | 0.8 | |

| 32 | - | 38 | 120 | 14 | 90 | 35 | 50 | 2.6 | 6 | 6 | 70 | 2 | 4 | 14 | 1.1 |

| 42.4 | - | 120 | 14 | 90 | 35 | 55 | 2.6 | 6 | 6 | 70 | 2 | 4 | 14 | 1.1 | |

| 40 | - | 44.5 | 130 | 14 | 100 | 38 | 58 | 2.6 | 6 | 7 | 80 | 3 | 4 | 14 | 1.2 |

| 46.3 | - | 130 | 14 | 100 | 38 | 62 | 2.6 | 6 | 7 | 80 | 3 | 4 | 14 | 1.2 | |

| 50 | - | 57 | 140 | 14 | 110 | 38 | 70 | 2.9 | 6 | 8 | 90 | 3 | 4 | 14 | 1.4 |

| 60.3 | - | 140 | 14 | 110 | 38 | 74 | 2.9 | 6 | 8 | 90 | 3 | 4 | 14 | 1.4 | |

| 65 | 76.1 | - | 160 | 14 | 130 | 38 | 88 | 2.9 | 6 | 9 | 110 | 3 | 4 | 14 | 1.7 |

| 80 | 88.9 | - | 190 | 16 | 150 | 42 | 102 | 3.2 | 8 | 10 | 128 | 3 | 4 | 18 | 2.7 |

| 100 | - | 108 | 210 | 16 | 170 | 45 | 122 | 3.6 | 8 | 10 | 148 | 3 | 4 | 18 | 3.3 |

| 114.3 | - | 210 | 16 | 170 | 45 | 130 | 3.6 | 8 | 10 | 148 | 3 | 4 | 18 | 3.2 | |

| 125 | - | 133 | 240 | 18 | 200 | 48 | 148 | 4 | 8 | 10 | 178 | 3 | 8 | 18 | 4.6 |

| 139.7 | - | 240 | 18 | 200 | 48 | 155 | 4 | 8 | 10 | 178 | 3 | 8 | 18 | 4.4 | |

| 150 | - | 159 | 265 | 18 | 225 | 48 | 172 | 4.5 | 10 | 12 | 202 | 3 | 8 | 18 | 5.3 |

| 158.3 | - | 265 | 18 | 225 | 48 | 184 | 4.5 | 10 | 12 | 202 | 3 | 8 | 18 | 5.0 | |

| 200 | 219.1 | - | 320 | 20 | 280 | 55 | 236 | 5.9 | 10 | 15 | 258 | 3 | 8 | 18 | 8.0 |

| 250 | - | 267 | 375 | 22 | 335 | 60 | 282 | 6.3 | 12 | 15 | 312 | 3 | 12 | 18 | 11.2 |

| 273 | - | 375 | 22 | 335 | 60 | 290 | 6.3 | 12 | 15 | 312 | 3 | 12 | 18 | 10.9 | |

| 300 | 323.9 | - | 440 | 22 | 395 | 62 | 342 | 7.1 | 12 | 15 | 365 | 4 | 12 | 22 | 14.3 |

| 350 | 355.6 | - | 490 | 22 | 445 | 62 | 385 | 7.1 | 12 | 15 | 415 | 4 | 12 | 22 | 18.5 |

| - | 368 | 490 | 22 | 445 | 62 | 385 | 7.1 | 12 | 15 | 415 | 4 | 12 | 22 | 16.8 | |

| 400 | 406.6 | - | 540 | 22 | 495 | 65 | 438 | 7.1 | 12 | 15 | 465 | 4 | 16 | 22 | 21.3 |

| - | 419 | 540 | 22 | 495 | 65 | 438 | 7.1 | 12 | 15 | 465 | 4 | 16 | 22 | 19.1 | |

| 500 | 508 | - | 645 | 24 | 600 | 68 | 538 | 7.1 | 12 | 15 | 570 | 4 | 20 | 22 | 28.7 |

| 600 | 610 | - | 755 | 24 | 705 | 70 | 640 | 7.1 | 12 | 16 | 670 | 5 | 20 | 26 | 34.8 |

| 700 | 711 | - | 860 | 24 | 810 | 70 | 740 | 7.1 | 12 | 16 | 775 | 5 | 24 | 26 | 40.9 |

| 800 | 813 | - | 975 | 24 | 920 | 70 | 842 | 7.1 | 12 | 16 | 880 | 5 | 24 | 30 | 49.2 |

| 900 | 914 | - | 1075 | 26 | 1020 | 70 | 942 | 7.1 | 12 | 16 | 980 | 5 | 24 | 30 | 58.1 |

| 1000 | 1016 | - | 1175 | 26 | 1120 | 70 | 1045 | 7.1 | 16 | 16 | 1080 | 5 | 28 | 30 | 63.5 |

| 1200 | 1220 | - | 1405 | 28 | 1340 | 90 | 1248 | 8 | 16 | 20 | 1295 | 5 | 32 | 33 | 100.2 |

| 1400 | 1420 | - | 1630 | 32 | 1560 | 90 | 1452 | 8 | 16 | 20 | 1510 | 5 | 36 | 36 | 142.8 |

| 1600 | 1620 | - | 1830 | 34 | 1760 | 90 | 1655 | 9 | 16 | 20 | 1710 | 5 | 40 | 36 | 174.4 |

| 1800 | 1820 | - | 2045 | 36 | 1970 | 100 | 1855 | 10 | 16 | 20 | 1920 | 5 | 44 | 39 | 227.0 |

| 2000 | 2020 | - | 2265 | 38 | 2180 | 110 | 2058 | 11 | 16 | 25 | 2125 | 5 | 48 | 42 | 292.1 |

| 2200 | 2220 | - | 2475 | 42 | 2390 | 115 | 2260 | 12 | 18 | 25 | 2335 | 6 | 52 | 42 | 366.3 |

| 2400 | 2420 | - | 2685 | 44 | 2600 | 125 | 2462 | 13 | 18 | 25 | 2545 | 6 | 56 | 42 | 448.5 |

| 2600 | 2620 | - | 2905 | 46 | 2810 | 130 | 2665 | 14 | 18 | 25 | 2750 | 6 | 60 | 48 | 540.2 |

| 2800 | 2820 | - | 3115 | 48 | 3020 | 135 | 2865 | 15 | 18 | 30 | 2960 | 6 | 64 | 48 | 630.0 |

| 3000 | 3020 | - | 3315 | 50 | 3220 | 140 | 3068 | 16 | 18 | 30 | 3160 | 6 | 68 | 48 | 716.3 |

| 3200 | 3220 | - | 3525 | 54 | 3430 | 150 | 3272 | 16 | 20 | 30 | 3370 | 6 | 72 | 48 | 854.4 |

| 3400 | 3420 | - | 3735 | 46 | 3640 | 160 | 3475 | 18 | 20 | 35 | 3580 | 6 | 76 | 48 | 887.8 |

| 3600 | 3620 | - | 3970 | 60 | 3860 | 165 | 3678 | 18 | 20 | 35 | 3790 | 6 | 80 | 56 | 1202.4 |

1.Dimensions are in millimeters(mm).

2.Dimensions can be specified by different purchasers.

Materials of DIN Weld Neck Flanges:

DIN weld neck flanges are available in various materials to suit different applications and operating conditions. The material selection for DIN weld neck flanges depends on factors such as temperature, pressure, corrosion resistance, and compatibility with the conveyed fluid or gas.

Grades of Carbon Steel:

ASTM A105: This is a common grade of carbon steel used for weld neck flanges. It is a forged carbon steel specifically designed for high-temperature service and offers excellent weldability and toughness.

ASTM A350 LF2: LF2 is a low-temperature carbon steel grade commonly used for weld neck flanges in applications where low-temperature toughness is required.

ASTM A694 F52/F60/F65/F70: These grades are high-yield carbon steel materials used for weld neck flanges in applications requiring high strength and impact resistance.

Grades of Stainless Steel:

ASTM A182 F304/F304L: These grades of stainless steel are austenitic and commonly used for weld neck flanges. They offer good corrosion resistance, excellent weldability, and are suitable for a wide range of applications.

ASTM A182 F316/F316L: Similar to F304/F304L, these grades are also austenitic stainless steels with improved corrosion resistance, particularly in chloride environments.

ASTM A182 F321: F321 is an austenitic stainless steel grade containing titanium, which provides enhanced resistance to intergranular corrosion. It is often used for weld neck flanges in high-temperature applications.

ASTM A182 F347: F347 is a stabilized stainless steel grade with the addition of niobium, which improves its resistance to intergranular corrosion. It is commonly used for weld neck flanges in applications involving elevated temperatures.

How to install weld neck flanges:

Installing weld neck flanges requires careful attention to ensure a proper and secure connection. Here are the general steps to follow for weld neck flange installation:

Preparation: Ensure that the pipe ends and flange surfaces are clean and free from dirt, debris, and contaminants. Check that the flange and pipe are of the correct size and material, and verify that they are compatible.

Alignment: Align the flange with the pipe, ensuring that the bolt holes on the flange match the ones on the pipe. The weld bevel on the flange should be aligned with the beveled end of the pipe.

Welding: Tack weld the flange to the pipe at several points around the circumference. These tack welds hold the flange in place during the final welding process.

Welding Neck: Weld the neck of the flange to the pipe using the appropriate welding technique (e.g., TIG or MIG welding). Follow the recommended welding procedures and ensure proper penetration and fusion between the flange and pipe.

Weld Quality: Inspect the weld for any defects, such as cracks, incomplete penetration, or excessive porosity. Ensure that the weld meets the required quality standards and specifications.

Post-Weld Treatment: After welding, perform any required post-weld treatments, such as heat treatment or stress relieving, as specified by the applicable codes and standards.

Bolting: Once the weld is complete and the flange-to-pipe connection is secure, proceed with bolting the flange to the mating flange or equipment. Use appropriate gaskets and bolts/nuts, following the recommended tightening sequence and torque values specified by the flange manufacturer or industry standards.

Inspection and Testing: Inspect the completed installation for any visible defects, such as misalignment or leaks. Perform pressure testing, if required, to ensure the integrity and reliability of the flange connection.

Applications of DIN 2631 Weld Neck Flanges:

DIN 2631 weld neck flanges are specifically designed for use in specific applications where their unique characteristics are required. Here are some common applications of DIN 2631 weld neck flanges:

Oil and Gas Industry: DIN 2631 Weld Neck Flanges are widely used in the oil and gas industry for connecting pipes and equipment in refineries, offshore platforms, pipelines, and petrochemical plants. They are suitable for high-pressure and high-temperature applications commonly found in this industry.

Chemical Processing: These flanges are employed in chemical processing plants for connecting pipelines, reactors, and other equipment. They provide a secure and leak-free connection, ensuring the safe handling and transportation of chemicals and corrosive fluids.

Power Generation: DIN 2631 Weld Neck Flanges are utilized in power plants, including thermal power plants and nuclear power plants. They are used for connecting pipes in boiler systems, steam lines, and other critical applications that require high-pressure and high-temperature capabilities.

Water Treatment: These flanges find application in water treatment plants for connecting pipes and equipment involved in water supply, wastewater treatment, and desalination processes. They are suitable for handling water at various temperatures and pressures.

Pharmaceutical and Food Industries: DIN 2631 Weld Neck Flanges are utilized in pharmaceutical and food processing facilities. They provide a hygienic and reliable connection for pipes carrying sterile fluids, chemicals, and food-grade materials.

Shipbuilding and Marine Industry: These flanges are used in shipbuilding and marine applications, including shipyards, offshore platforms, and marine vessels. They are employed for connecting pipes and equipment in various systems such as fuel lines, cooling systems, and hydraulic systems.

HVAC and Plumbing Systems: DIN 2631 Weld Neck Flanges are employed in heating, ventilation, air conditioning (HVAC), and plumbing systems. They provide a secure connection for pipes carrying hot water, steam, or chilled fluids.

General Industrial Applications: These flanges have widespread use in various industrial sectors, including manufacturing, construction, and infrastructure. They are suitable for connecting pipelines in industrial processes that involve high-pressure fluids or gases.