Shaanxi Peter International Trade Co., Ltd. |

|

Verified Suppliers

|

|

MSS SP-75 Reducing Tee Pipe Fittings Reducing Tees Unequal Tees WPHY for High-pressure Gas and Oil

Transmission Systems

Product Introduction:

MSS SP-75 is a standard practice that governs the manufacturing of high-strength, butt-welding fittings for use in high-pressure gas and oil transmission systems. These fittings are made from carbon and low-alloy steel and are used in various applications such as pipelines, compressor stations, metering and regulating stations.

The standard covers dimensions, tolerances, ratings, testing, materials, chemical and tensile properties, heat treatment, notch toughness properties, manufacture, inspection, certification, and marking for butt-welding fittings with a nominal pipe size (NPS) of 60 and smaller.

MSS SP-75 fittings are classified into seven different classes based on their minimum yield strength: WPHY-42, WPHY-46, WPHY-52, WPHY-56, WPHY-60, WPHY-65, and WPHY-70. The "WP" stands for "wrought pipe" or "wrought plate," while "HY" denotes "high yield."

These fittings, such as long radius elbows, 3R elbows, straight tees, reducing tees, caps, and reducers, are commonly used to connect API 5L pipes or ASTM A694 forged pipe flanges.

In high-pressure oil and gas pipeline fittings, MSS SP-75 Grade WPHY 60, 65, and 70 are frequently utilized. For WPHY-42, 46, 52, and 56, which operate in medium-high pressure pipelines, clients may choose fittings made from ASTM A234 WPB or WPC instead.

Materials and Manufacturing Methods of MSS SP-75 Reducing Tees:

MSS SP 75 pipe fittings must be manufactured using fully killed steels produced through the open hearth, basic oxygen, or electric furnace process. These materials include blooms, billets, slabs, high-quality forging bars, plates, seamless pipes, or fusion-welded pipes. Welding procedures must comply with Section IX of the ASME Boiler and Pressure Vessel Code, as well as relevant ASTM and API specifications. Post-weld heat treatment should adhere to the guidelines outlined in Section VIII, Division 1 of the ASME Boiler and Pressure Vessel Code. The welding ends (bevels) of the fittings must be provided with varying wall thicknesses.

The manufacturing of MSS SP 75 WPHY pipe fittings can be easily accomplished through forging, hammering, pressing, piercing, rolling, extruding, upsetting, welding, or a combination of these methods. The final products must be devoid of harmful defects or the need for welding repairs. Some customers may request machining and grinding to address surface imperfections.

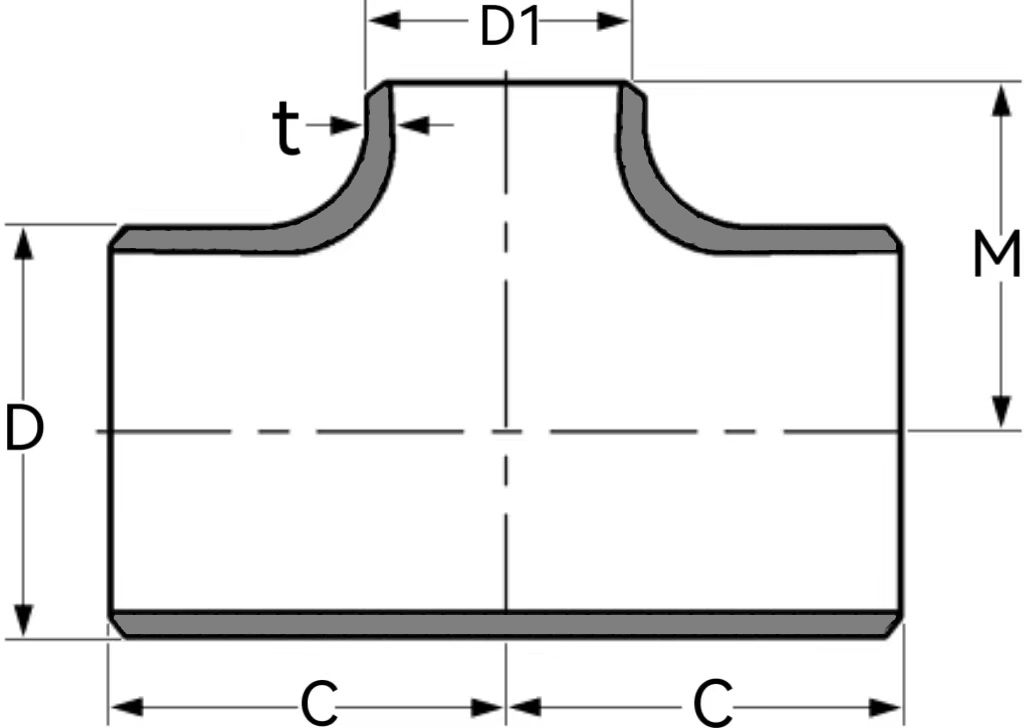

MSS SP-75 Reducing Tees/Unequal Tees Dimensions:

| MSS SP-75 Reducing Tee Dimensions | ||||

| Size | Outside Diameter | Outside Diameter | Center to End | Center to End |

| NPS | D | D1 | C | M |

| 16*16*14 | 16 | 14 | 12 | 12 |

| 16*16*12 | 16 | 12.75 | 12 | 11.62 |

| 16*16*10 | 16 | 10.75 | 12 | 11.12 |

| 16*16*8 | 16 | 8.62 | 12 | 10.75 |

| 16*16*6 | 16 | 6.62 | 12 | 10.38 |

| 18*18*16 | 18 | 16 | 13.5 | 13 |

| 18*18*14 | 18 | 14 | 13.5 | 13 |

| 18*18*12 | 18 | 12.75 | 13.5 | 12.62 |

| 18*18*10 | 18 | 10.75 | 13.5 | 12.12 |

| 18*18*8 | 18 | 8.62 | 13.5 | 11.75 |

| 20*20*18 | 20 | 18 | 15 | 14.5 |

| 20*20*16 | 20 | 16 | 15 | 14 |

| 20*20*14 | 20 | 14 | 15 | 14 |

| 20*20*12 | 20 | 12.75 | 15 | 13.62 |

| 20*20*10 | 20 | 10.75 | 15 | 13.12 |

| 20*20*8 | 20 | 8.62 | 15 | 12.75 |

| 22*22*20 | 22 | 20 | 16.5 | 16 |

| 22*22*18 | 22 | 18 | 16.5 | 15.5 |

| 22*22*16 | 22 | 16 | 16.5 | 15 |

| 22*22*14 | 22 | 14 | 16.5 | 15 |

| 22*22*12 | 22 | 12.75 | 16.5 | 14.62 |

| 22*22*10 | 22 | 10.75 | 16.5 | 14.12 |

| 24*24*22 | 24 | 22 | 17 | 17 |

| 24*24*20 | 24 | 20 | 17 | 17 |

| 24*24*18 | 24 | 18 | 17 | 16.5 |

| 24*24*16 | 24 | 16 | 17 | 16 |

| 24*24*14 | 24 | 14 | 17 | 16 |

| 24*24*12 | 24 | 12.75 | 17 | 15.62 |

| 24*24*10 | 24 | 10.75 | 17 | 15.12 |

| 26*26*24 | 26 | 24 | 19.5 | 19 |

| 26*26*22 | 26 | 22 | 19.5 | 18.5 |

| 26*26*20 | 26 | 20 | 19.5 | 18 |

| 26*26*18 | 26 | 18 | 19.5 | 17.5 |

| 26*26*16 | 26 | 16 | 19.5 | 17 |

| 26*26*14 | 26 | 14 | 19.5 | 17 |

| 26*26*12 | 26 | 12.75 | 19.5 | 16.62 |

| 28*28*26 | 28 | 26 | 20.5 | 20.5 |

| 28*28*24 | 28 | 24 | 20.5 | 20 |

| 28*28*22 | 28 | 22 | 20.5 | 19.5 |

| 28*28*20 | 28 | 20 | 20.5 | 19 |

| 28*28*18 | 28 | 18 | 20.5 | 18.5 |

| 28*28*16 | 28 | 16 | 20.5 | 18 |

| 28*28*14 | 28 | 14 | 20.5 | 18 |

| 28*28*12 | 28 | 12.75 | 20.5 | 17.62 |

| 30*30*28 | 30 | 28 | 22 | 21.5 |

| 30*30*26 | 30 | 26 | 22 | 21.5 |

| 30*30*24 | 30 | 24 | 22 | 21 |

| 30*30*22 | 30 | 22 | 22 | 20.5 |

| 30*30*20 | 30 | 20 | 22 | 20 |

| 30*30*18 | 30 | 18 | 22 | 19.5 |

| 30*30*16 | 30 | 16 | 22 | 19 |

| 30*30*14 | 30 | 14 | 22 | 19 |

| 30*30*12 | 30 | 12.75 | 22 | 18.62 |

| 30*30*10 | 30 | 10.75 | 22 | 18.12 |

| 32*32*30 | 32 | 30 | 23.5 | 23 |

| 32*32*28 | 32 | 28 | 23.5 | 22.5 |

| 32*32*26 | 32 | 26 | 23.5 | 22.5 |

| 32*32*24 | 32 | 24 | 23.5 | 22 |

| 32*32*22 | 32 | 22 | 23.5 | 21.5 |

| 32*32*20 | 32 | 20 | 23.5 | 21 |

| 32*32*18 | 32 | 18 | 23.5 | 20.5 |

| 32*32*16 | 32 | 16 | 23.5 | 20 |

| 32*32*14 | 32 | 14 | 23.5 | 20 |

| 34*34*32 | 34 | 32 | 25 | 24.5 |

| 34*34*30 | 34 | 30 | 25 | 24 |

| 34*34*28 | 34 | 28 | 25 | 23.5 |

| 34*34*26 | 34 | 26 | 25 | 23.5 |

| 34*34*24 | 34 | 24 | 25 | 23 |

| 34*34*22 | 34 | 22 | 25 | 22.5 |

| 34*34*20 | 34 | 20 | 25 | 22 |

| 34*34*18 | 34 | 18 | 25 | 21.5 |

| 34*34*16 | 34 | 16 | 25 | 21 |

| 36*36*34 | 36 | 34 | 26.5 | 26 |

| 36*36*32 | 36 | 32 | 26.5 | 25.5 |

| 36*36*30 | 36 | 30 | 26.5 | 25 |

| 36*36*28 | 36 | 28 | 26.5 | 24.5 |

| 36*36*26 | 36 | 26 | 26.5 | 24.5 |

| 36*36*24 | 36 | 24 | 26.5 | 24 |

| 36*36*22 | 36 | 22 | 26.5 | 23.5 |

| 36*36*20 | 36 | 20 | 26.5 | 23 |

| 36*36*18 | 36 | 18 | 26.5 | 22.5 |

| 36*36*16 | 36 | 16 | 26.5 | 22 |

| 38*38*36 | 38 | 36 | 28 | 28 |

| 38*38*34 | 38 | 34 | 28 | 27.5 |

| 38*38*32 | 38 | 32 | 28 | 27 |

| 38*38*30 | 38 | 30 | 28 | 26.5 |

| 38*38*28 | 38 | 28 | 28 | 25.5 |

| 38*38*26 | 38 | 26 | 28 | 25.5 |

| 38*38*24 | 38 | 24 | 28 | 25 |

| 38*38*22 | 38 | 22 | 28 | 24.5 |

| 38*38*20 | 38 | 20 | 28 | 24 |

| 38*38*18 | 38 | 18 | 28 | 23.5 |

| 40*40*38 | 40 | 38 | 29.5 | 29.5 |

| 40*40*36 | 40 | 36 | 29.5 | 29 |

| 40*40*34 | 40 | 34 | 29.5 | 28.5 |

| 40*40*32 | 40 | 32 | 29.5 | 28 |

| 40*40*30 | 40 | 30 | 29.5 | 27.5 |

| 40*40*28 | 40 | 28 | 29.5 | 26.5 |

| 40*40*26 | 40 | 26 | 29.5 | 26.5 |

| 40*40*24 | 40 | 24 | 29.5 | 26 |

| 40*40*22 | 40 | 22 | 29.5 | 25.5 |

| 40*40*20 | 40 | 20 | 29.5 | 25 |

| 40*40*18 | 40 | 18 | 29.5 | 24.5 |

| 42*42*36 | 42 | 36 | 30 | 28 |

| 42*42*34 | 42 | 34 | 30 | 28 |

| 42*42*32 | 42 | 32 | 30 | 28 |

| 42*42*30 | 42 | 30 | 30 | 28 |

| 42*42*28 | 42 | 28 | 30 | 27.5 |

| 42*42*26 | 42 | 26 | 30 | 27.5 |

| 42*42*24 | 42 | 24 | 30 | 26 |

| 42*42*22 | 42 | 22 | 30 | 26 |

| 42*42*20 | 42 | 20 | 30 | 26 |

| 42*42*18 | 42 | 18 | 30 | 25.5 |

| 42*42*16 | 42 | 16 | 30 | 25 |

| 44*44*42 | 44 | 42 | 32 | 30 |

| 44*44*40 | 44 | 40 | 32 | 29.5 |

| 44*44*38 | 44 | 38 | 32 | 29 |

| 44*44*36 | 44 | 36 | 32 | 28.5 |

| 44*44*34 | 44 | 34 | 32 | 28.5 |

| 44*44*32 | 44 | 32 | 32 | 28 |

| 44*44*30 | 44 | 30 | 32 | 28 |

| 44*44*28 | 44 | 28 | 32 | 27.5 |

| 44*44*26 | 44 | 26 | 32 | 27.5 |

| 44*44*24 | 44 | 24 | 32 | 27.5 |

| 44*44*22 | 44 | 22 | 32 | 27 |

| 44*44*20 | 44 | 20 | 32 | 27 |

| 46*46*44 | 46 | 44 | 33.5 | 31.5 |

| 46*46*42 | 46 | 42 | 33.5 | 31 |

| 46*46*40 | 46 | 40 | 33.5 | 30.5 |

| 46*46*38 | 46 | 38 | 33.5 | 30 |

| 46*46*36 | 46 | 36 | 33.5 | 30 |

| 46*46*34 | 46 | 34 | 33.5 | 29.5 |

| 46*46*32 | 46 | 32 | 33.5 | 29.5 |

| 46*46*30 | 46 | 30 | 33.5 | 29 |

| 46*46*28 | 46 | 28 | 33.5 | 29 |

| 46*46*26 | 46 | 26 | 33.5 | 29 |

| 46*46*24 | 46 | 24 | 33.5 | 28.5 |

| 46*46*22 | 46 | 22 | 33.5 | 28.5 |

| 48*48*46 | 18 | 46 | 35 | 33 |

| 48*48*44 | 18 | 44 | 35 | 33 |

| 48*48*42 | 18 | 42 | 35 | 32 |

| 48*48*40 | 18 | 40 | 35 | 32 |

| 48*48*38 | 18 | 38 | 35 | 32 |

| 48*48*36 | 18 | 36 | 35 | 31 |

| 48*48*34 | 18 | 34 | 35 | 31 |

| 48*48*32 | 18 | 32 | 35 | 31 |

| 48*48*30 | 18 | 30 | 35 | 30 |

| 48*48*28 | 18 | 28 | 35 | 30 |

| 48*48*26 | 18 | 26 | 35 | 30 |

| 48*48*24 | 18 | 24 | 35 | 29 |

| 48*48*22 | 18 | 22 | 35 | 29 |

| 48*48*20 | 18 | 20 | 35 | 29 |

| 48*48*18 | 18 | 18 | 35 | 28.5 |

| 48*48*16 | 18 | 16 | 35 | 28 |

| 50*50*48 | 50 | 48 | 36.75 | 34.5 |

| 50*50*42 | 50 | 42 | 36.75 | 33 |

| 50*50*36 | 50 | 36 | 36.75 | 32.5 |

| 50*50*30 | 50 | 30 | 36.75 | 31.5 |

| 50*50*24 | 50 | 24 | 36.75 | 30 |

| 50*50*20 | 50 | 20 | 36.75 | 30 |

| 52*52*50 | 52 | 50 | 38.5 | 35.75 |

| 52*52*48 | 52 | 48 | 38.5 | 35.75 |

| 52*52*42 | 52 | 42 | 38.5 | 34.5 |

| 52*52*36 | 52 | 36 | 38.5 | 34 |

| 52*52*30 | 52 | 30 | 38.5 | 32.75 |

| 52*52*24 | 52 | 24 | 38.5 | 31.25 |

| 54*54*52 | 54 | 52 | 40 | 37.25 |

| 54*54*48 | 54 | 48 | 40 | 37.25 |

| 54*54*42 | 54 | 42 | 40 | 35.63 |

| 54*54*36 | 54 | 36 | 40 | 35 |

| 54*54*30 | 54 | 30 | 40 | 34 |

| 54*54*24 | 54 | 24 | 40 | 31.38 |

| 56*56*54 | 56 | 54 | 41.5 | 38.5 |

| 56*56*48 | 56 | 48 | 41.5 | 37 |

| 56*56*42 | 56 | 42 | 41.5 | 36.5 |

| 56*56*36 | 56 | 36 | 41.5 | 35.5 |

| 56*56*30 | 56 | 30 | 41.5 | 33.75 |

| 56*56*24 | 56 | 24 | 41.5 | 33.75 |

| 58*58*56 | 58 | 56 | 43 | 40 |

| 58*58*54 | 58 | 54 | 43 | 40 |

| 58*58*48 | 58 | 48 | 43 | 38.5 |

| 58*58*42 | 58 | 42 | 43 | 37.5 |

| 58*58*36 | 58 | 36 | 43 | 36.5 |

| 58*58*30 | 58 | 30 | 43 | 35 |

| 60*60*58 | 60 | 58 | 44 | 41.5 |

| 60*60*54 | 60 | 54 | 44 | 40.5 |

| 60*60*48 | 60 | 48 | 44 | 40 |

| 60*60*42 | 60 | 42 | 44 | 39 |

| 60*60*36 | 60 | 36 | 44 | 38 |

| 60*60*30 | 60 | 30 | 44 | 36 |

Grades of MSS SP-75 WPHY Reducing Tees/Unequal Tees:

MSS SP-75 specifies several grades, known as WPHY grades, for butt-welding fittings. These grades correspond to different minimum yield strengths and are used to categorize the fittings based on their mechanical properties. The WPHY grades specified in MSS SP-75 include:

WPHY-42: This grade has a minimum yield strength of 42,000 psi (290 MPa). It is commonly used in applications that require medium-strength fittings.

WPHY-46: This grade has a minimum yield strength of 46,000 psi (315 MPa). It offers slightly higher strength compared to WPHY-42 and is suitable for applications that require increased toughness.

WPHY-52: This grade has a minimum yield strength of 52,000 psi (360 MPa). It provides higher strength compared to the previous grades and is used in applications that require increased pressure and temperature resistance.

WPHY-56: This grade has a minimum yield strength of 56,000 psi (385 MPa). It offers further increased strength and is suitable for demanding applications that require higher pressure and temperature capabilities.

WPHY-60: This grade has a minimum yield strength of 60,000 psi (415 MPa). It provides even higher strength compared to the previous grades and is commonly used in applications with more demanding requirements.

WPHY-65: This grade has a minimum yield strength of 65,000 psi (450 MPa). It offers increased strength and toughness, making it suitable for high-pressure and high-temperature applications.

WPHY-70: This grade has a minimum yield strength of 70,000 psi (485 MPa). It provides the highest strength among the WPHY grades and is used in applications that require excellent mechanical properties and resistance to extreme conditions.

Applications of MSS SP-75 WPHY Reducing Tees/Equal Tees:

MSS SP-75 WPHY reducing tees/unequal tees, which are butt-welding fittings made from high-strength carbon and low-alloy steel, have various applications in high-pressure gas and oil transmission systems.

Flow Distribution: Reducing tees are used to distribute flow from a main pipeline into two branch pipelines of different sizes. This helps in directing the flow efficiently based on the requirements of the system.

Branch Connections: Unequal tees are used for creating branch connections in pipelines where the flow needs to be diverted or split into different directions.

Pressure Control: These fittings are used in systems where pressure control is crucial. The design of reducing tees helps in managing pressure drops effectively while ensuring smooth flow transitions.

Space-Constrained Installations: In situations where space is limited, unequal tees can be used to connect pipes of different sizes without requiring additional fittings or adapters.

Pipeline Expansion or Modification: When modifying or expanding existing pipelines, MSS SP-75 WPHY reducing tees/unequal tees are utilized to accommodate changes in flow requirements or to introduce new branches into the system.