Shaanxi Peter International Trade Co., Ltd. |

|

Verified Suppliers

|

|

ASME B16.9 ASTM A420 WPL6 Pipe Fittings Elbow Carbon Steel 3D Radius 45 Degree Elbow for Industrial Piping Systems

Product Introduction of ASME B16.9 3D Radius Elbows:

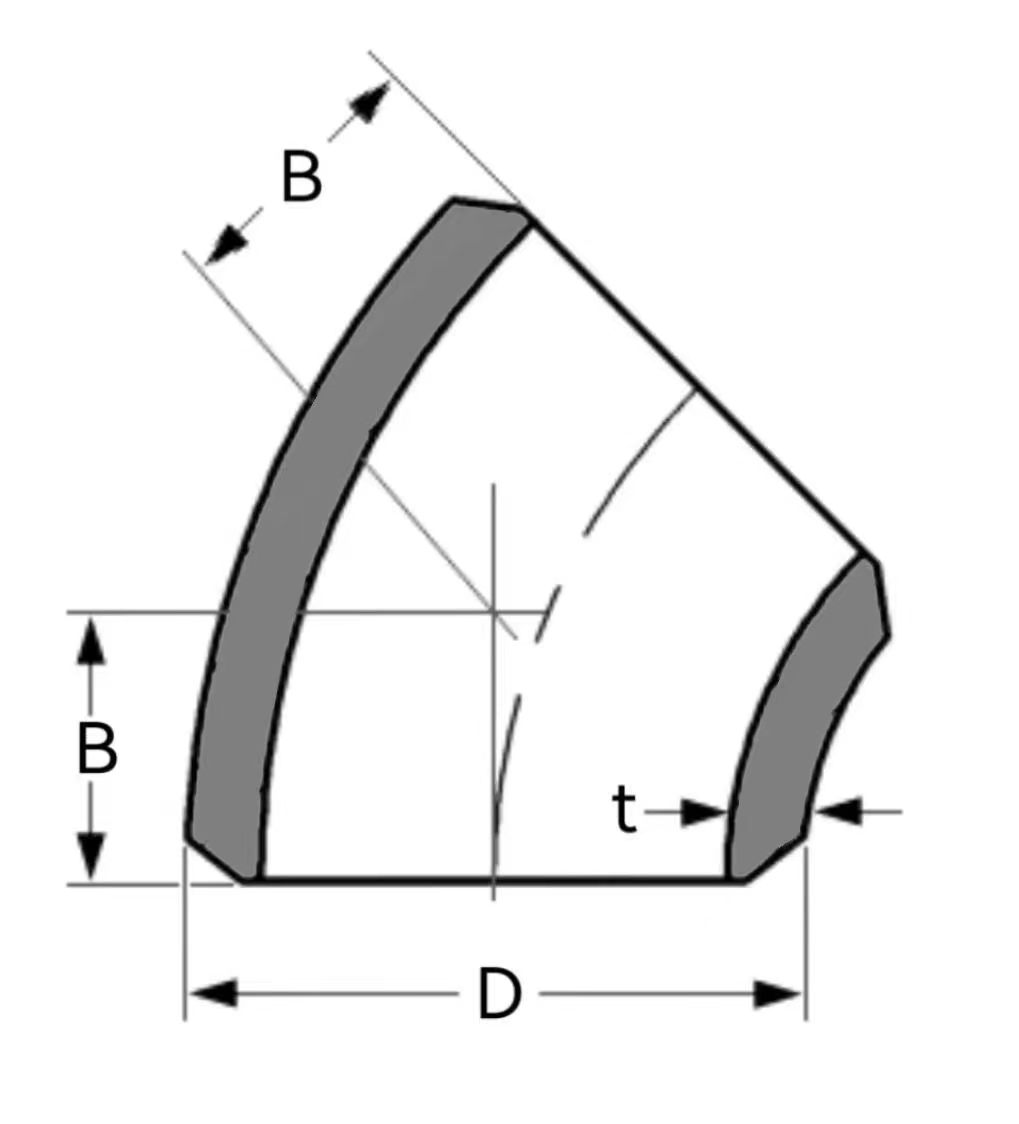

According to ASME B16.9, the standard 3D radius elbow is available in 45° or 90° angles. The center-to-end dimension of a 3D radius elbow is significantly larger compared to a long radius (L/R) elbow, as it is calculated as "3 times the nominal pipe size (NPS)" in inches.

The larger center-to-end dimension of a 3D radius elbow provides several benefits, including smoother flow characteristics. The increased length allows for a more gradual change in direction compared to an L/R elbow, resulting in reduced turbulence and lower pressure drop within the piping system.

The smoother flow characteristics offered by a 3D radius elbow can be advantageous in applications where minimizing pressure loss and maintaining efficient fluid flow are important. This is particularly relevant in industries such as oil and gas, chemical processing, and power generation, where maintaining optimal flow conditions is crucial for system performance.

While a 3D radius elbow provides smoother flow characteristics, it also occupies a larger physical space compared to an L/R elbow. Therefore, considerations regarding the available space and overall system design should be taken into account when selecting the appropriate elbow for a specific application.

By offering a larger radius and a more gradual change in direction, the 3D radius elbow contributes to improved flow characteristics, reduced pressure drop, and enhanced overall efficiency in piping systems.

Description of ASTM A420 WPL6:

ASTM A420 WPL6 is a grade of material specified in the ASTM A420 standard for pipe fittings made of wrought carbon steel and alloy steel intended for low-temperature service.

Composition: ASTM A420 WPL6 fittings are made from carbon steel or low-alloy steel with a specified chemical composition that includes elements such as carbon, manganese, phosphorus, sulfur, silicon, nickel, chromium, molybdenum, and other alloying elements.

Mechanical Properties: The mechanical properties of ASTM A420 WPL6 fittings are designed to meet specific requirements for tensile strength, yield strength, elongation, and impact toughness at low temperatures. These properties ensure the fittings can withstand the stresses and conditions encountered in low-temperature service applications.

Low-Temperature Service: ASTM A420 WPL6 fittings are specifically intended for use in environments where low temperatures are a consideration. They are suitable for applications in industries such as oil and gas, petrochemical, and cryogenic systems where the piping systems operate at temperatures below ambient levels.

Impact Testing: ASTM A420 WPL6 fittings undergo impact testing at a specified temperature (typically -45°C) to ensure they possess the necessary toughness and resistance to brittle fracture under low-temperature conditions.

Weldability: ASTM A420 WPL6 fittings are weldable using common welding methods and techniques, enabling them to be installed and integrated into piping systems effectively.

ASME B16.9 45 Degree Elbow 3D Dimensions:

| ASME B16.9 45 Degree 3D Dimensions(MM) | ||

| NPS | D(outer dimension) | B(Center-to-End) |

| 1/2″ | 21.3 | … |

| 3/4″ | 26.7 | 24 |

| 1″ | 33.4 | 31 |

| 1 1/4″ | 42.2 | 39 |

| 1 1/2″ | 48.3 | 47 |

| 2″ | 60.3 | 63 |

| 2 1/2″ | 73 | 79 |

| 3″ | 88.9 | 95 |

| 3 1/2″ | 101.6 | 111 |

| 4″ | 114.3 | 127 |

| 5″ | 141.3 | 157 |

| 6″ | 168.3 | 189 |

| 8″ | 219.1 | 252 |

| 10″ | 273 | 316 |

| 12″ | 323.8 | 378 |

| 14″ | 355.6 | 441 |

| 16″ | 406.4 | 505 |

| 18″ | 457 | 568 |

| 20″ | 508 | 632 |

| 22″ | 559 | 694 |

| 24″ | 610 | 757 |

| 26″ | 660 | 821 |

| 28″ | 711 | 883 |

| 30″ | 762 | 964 |

| 32″ | 813 | 1010 |

| 34″ | 864 | 1073 |

| 36″ | 914 | 1135 |

| 38″ | 965 | 1200 |

| 40″ | 1016 | 1264 |

| 42″ | 1067 | 1326 |

| 44″ | 1118 | 1389 |

| 46″ | 1168 | 1453 |

| 48″ | 1219 | 1516 |

Grades of ASTM A420 3D Radius 45 Degree Elbows:

ASTM A420 is indeed the standard specification for pipe fittings made of carbon steel and alloy steel designed for low-temperature services. Among the various grades specified under ASTM A420, WPL6 is the most commonly used material grade. In addition to Grade WPL6, the standard also includes other grades such as WPL9, WPL3, and WPL8, each with different impact test temperatures corresponding to specific low-temperature service requirements:

These different grades with varying impact test temperatures allow for the selection of the most suitable material based on the specific low-temperature conditions in which the pipe fittings will be operating. It is essential to choose the appropriate grade to ensure that the fittings can withstand the required service conditions and maintain their integrity and performance at low temperatures.

Advantages of ASTM A420 WPL6:

Low-Temperature Performance: ASTM A420 WPL6 fittings are specifically designed to provide excellent performance and reliability in low-temperature environments. The material's composition and mechanical properties are tailored to ensure resistance to brittle fracture and maintain toughness at low temperatures, making them ideal for cryogenic applications.

Wide Range of Applications: ASTM A420 WPL6 fittings can be used in various industries and sectors that require low-temperature piping systems, such as oil and gas, petrochemical, chemical processing, LNG (liquefied natural gas) plants, and refrigeration systems. Their versatility makes them suitable for a range of applications where low temperatures are a concern.

High Strength and Durability: ASTM A420 WPL6 fittings offer high tensile strength, yield strength, and impact toughness, providing durability and reliability in demanding operating conditions. This ensures that the fittings can withstand the stresses and pressures encountered in low-temperature service without compromising performance.

Good Weldability: ASTM A420 WPL6 material is weldable using common welding techniques, allowing for easy fabrication and installation of piping systems. The weldability of WPL6 fittings facilitates efficient construction and maintenance of pipelines, reducing installation time and costs.

Usages of 45 Degree 3D Radius Elbows:

Change in Direction: A 45-degree 3D radius elbow is frequently employed when a change in direction of the piping system is required. It allows for a moderate change in flow direction while maintaining a larger radius curve. This makes it suitable for applications where a smooth transition is needed to minimize pressure drop and turbulence.

Flow Distribution: In piping systems that require equal or proportional flow distribution among multiple branches or lines, a 45-degree 3D radius elbow can be used. It helps balance the flow rate and pressure among the outlets, ensuring efficient fluid distribution.

Space Constraints: When space limitations exist, and a specific turn angle is necessary, a 45-degree 3D radius elbow can be a suitable choice. It provides a moderate change in direction while occupying less space compared to other elbows with sharper angles.

Process Piping: 45-degree 3D radius elbows find utility in various process piping applications across industries such as oil and gas, chemical processing, power generation, and more. They are commonly used when a moderate change in flow direction is required without compromising the flow efficiency or causing excessive pressure drop.

Plumbing Systems: In plumbing systems, 45-degree 3D radius elbows are employed for directing the flow of water, wastewater, or other fluids in residential, commercial, and industrial settings. They allow for smooth turns and help maintain the overall efficiency of the plumbing system.