SUZHOU MINGSTAR CO.,LTD |

|

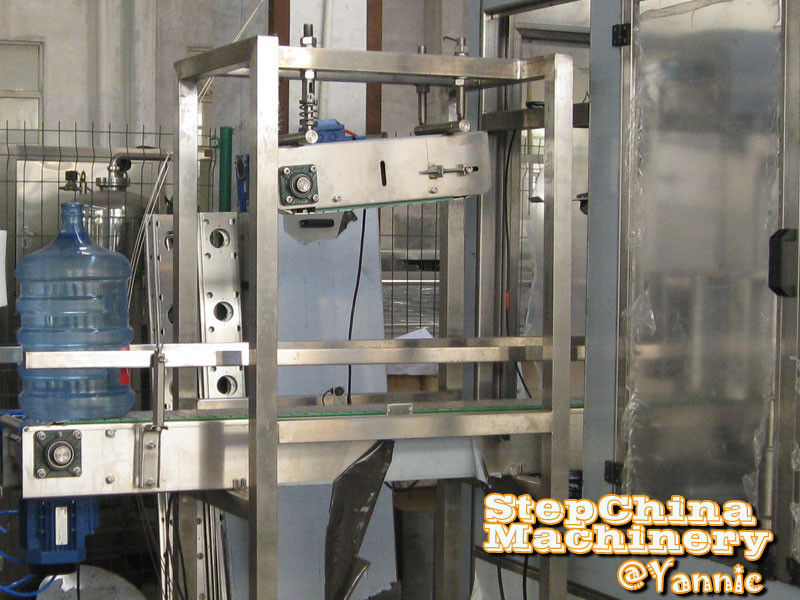

Automatic 5 Gallon Water Filling Machine 1000BPH , 18.9L Bottled Water Production Line

Description:

Quick Detail:

| 5 gallon water bottling line, 5 gallon water filling line | | |

| | | |

| | | |

Washing process:

Rotary type filling machine:

Gravity filling vlaves are steady working during filling every 5

gallon bottle. rotary type working is more

efficient than linear type. mechanical structure with gear wheel.

Chain press capping:

stainless steel chain for pressing cap with angles slowly. it's

steady and splash desgin for pressing cap

onto bottle mouth.

Cental control box:

Applications:

1. bottled purified water production.

2. bottled mineral water production.

Specifications:

1. Rated

capacity:

1000 B/H for 18.9l

2. Filling

material:

water

3. Bottle

type:

PET,PP, PC bottle;

4. Filling

type:

Bottom support type

5.

Cap:

plastic lid

6. Filling

temperature:

normal temperature

7.

Label:

PVC sleeve label

8. Conveyor

mode:

Conveyor belt

9.

Condition:

temperature: 10~40℃

humidity:no dew(≤95%)

10. Resource

power:

380V,50Hz,three phase

11. Efficiency:

>95%

Competitive Advantage:

1. high production standard.

2. reliable electronic elements: Mitsubishi, Siemens, Schneider.

3. Pneumatic parts: Airtac or Festo

4. Automatic control

5. Installation service and worker training.

FAQ

1) Can your factory provide the whole plant from A to Z?

A: Yes, we can provide the complete plant, from bottle blowing

machine, water purification plant, to filling packing plant.

2) Are all machinery your factory made?

A: Our factory make the water purification and filling packing

plants. We do not make the bottle blowing machinery, we have good

quality bottle blowing machinery partner, and we provide to

customer same long warranty time and good after service.

We shall connect the whole production line for test running before

shipment.

3) How can I know the machinery quality before I order?

A: Frist, we will invite you visiting our factory to check the

quality, and introduce our technology advantages. You will be easy

to compare ours equipment with others.

4) What certificates you can provide?

A: Our factory provide the CE, SGS, ISO, and accroding to some

countries, we also can provide the Pvoc, Coc, Soncap...ect

5) Can your factory make the bottle drawing, workshop layout, and

labels for us?

A: We can help customers design their own bottle shape, workshop

layout and label drawings, these jobs are free charge.

(Workshop layout is based on land size of client)

6) Installation and Training Time

A: We have professional engineer for oversea installaion and

training, they have much experience over 10 years working in this

industry. Clients need to pay round air ticket, visa charge,

accommodation and 100 USD/day. (PS: 100 USD/day is personal charge

for engineer, our company doesn’t take it.)