Shaanxi Peakrise Metal Co.,Ltd |

|

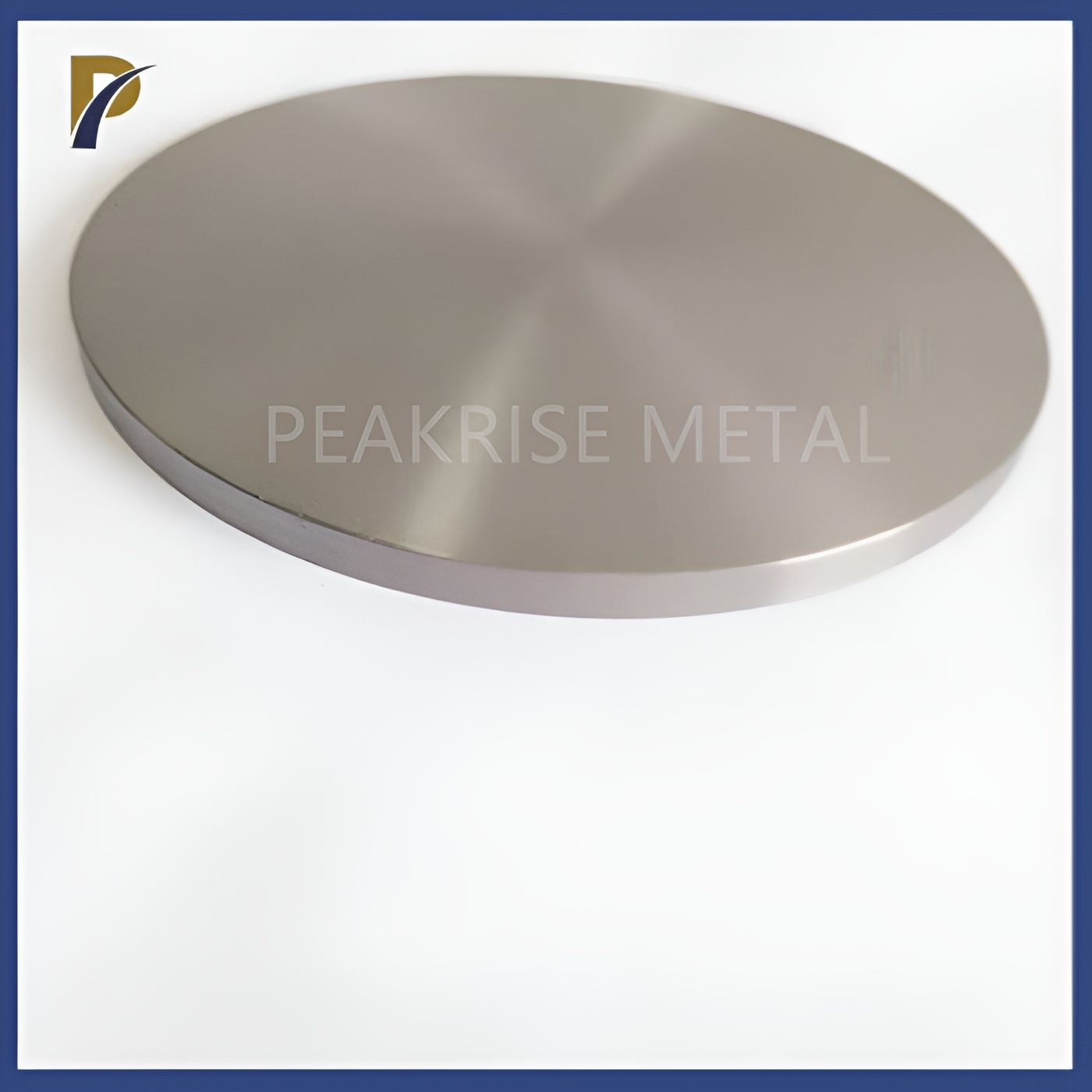

Molybdenum Copper Alloy Magnetron Sputtering Target

1. Description of Molybdenum Copper Alloy Magnetron Sputtering Target:

The preparation of molybdenum-copper alloy magnetron sputtering targets is mainly by infiltration method. First, molybdenum powder with coarse particle size is used to sinter into a molybdenum billet skeleton, and then infiltrated in copper liquid to obtain molybdenum-copper alloys with different copper contents. The obtained molybdenum-copper alloys , Fine organization, good arc breaking performance, good electrical conductivity, good thermal conductivity, and small thermal expansion. Using high-quality molybdenum powder and oxygen-free copper powder, applying isostatic pressing, and sintering to obtain a molybdenum-copper alloy with high copper content, which has excellent performance. Molybdenum-copper alloy is 40% higher than similar tungsten-copper composite materials, and has higher thermal conductivity, thermal and mechanical properties, and thermal expansion properties.

2. Parameter of Molybdenum Copper Alloy Magnetron Sputtering Target:

| Grade | Mo content % | Cu content % | Density (g/cm3) | Thermal conductivity (W/M.K) | Thermal expansion coefficient (10-6/K) |

| Mo85Cu15 | 85±1 | Balance | 10 | 160~180 | 6.8 |

| Mo80Cu20 | 80±1 | Balance | 9.9 | 170~190 | 7.7 |

| Mo70Cu30 | 70±1 | Balance | 9.8 | 180~200 | 9.1 |

| Mo60Cu40 | 60±1 | Balance | 9.66 | 210~250 | 10.3 |

| Mo50Cu50 | 50±1 | Balance | 9.54 | 230~270 | 11.5 |

| Mo40Cu60 | 40±1 | Balance | 9.43 | 280~290 | 11.8 |

3. Chemical of Molybdenum Copper Alloy Magnetron Sputtering Target:

| Grade | Alloy content % | Impurity element content (max.< %) | |||||||||

| Mo | Cu | W | Mg | Ca | Fe | C | N | H | O | Other Impurity Amount | |

| Mo40Cu60 | Remain | 60±2.0 | 0.015 | 0.01 | 0.01 | 0.01 | 0.015 | 0.01 | 0.01 | 0.01 | 0.01 |

| Mo45Cu55 | Remain | 55±2.0 | |||||||||

| Mo50Cu50 | Remain | 50±2.0 | |||||||||

| Mo55Cu45 | Remain | 45±2.0 | |||||||||

| Mo60Cu40 | Remain | 40±2.0 | |||||||||

| Mo65Cu35 | Remain | 35±2.0 | |||||||||

| Mo70Cu30 | Remain | 30±2.0 | |||||||||

| Mo75Cu25 | Remain | 25±2.0 | |||||||||

| Mo80Cu20 | Remain | 20±2.0 | |||||||||

| Mo85Cu15 | Remain | 15±2.0 | |||||||||

| Mo90Cu10 | Remain | 10±2.0 | |||||||||

4. Production method of Molybdenum Copper Alloy Magnetron Sputtering Target:

Liquid phase sintering method: After the molybdenum-copper mixed powder is pressed and formed, it is sintered in the liquid phase at 1300-1500°. The materials prepared by this method have poor uniformity, many closed voids, and the density is usually lower than 98%. It can improve the sintering activity, thereby improving the density of the molybdenum copper alloy. However, nickel activated sintering will significantly reduce the electrical and thermal conductivity of the material, and the introduction of impurities in mechanical alloying will also reduce the conductivity of the material; the oxide co-reduction method to prepare powders is cumbersome in the process, low in production efficiency, and difficult to mass produce.

Molybdenum skeleton infiltration method: First, molybdenum powder is pressed into shape, and sintered into a molybdenum skeleton with a certain porosity, and then copper is infiltrated. This method is suitable for molybdenum copper products with low copper content. Although the heat resistance is not as good as that of tungsten copper, it is better than some heat-resistant materials, so the application prospect is better.

5. Characteristic of Molybdenum Copper Alloy Magnetron Sputtering Target:

Molybdenum-copper alloy combines the advantages of copper and molybdenum, high strength, high specific gravity, high temperature resistance, arc ablation resistance, good electrical and thermal conductivity, and good processing performance. Using high-quality molybdenum powder and oxygen-free copper powder, applying isostatic pressing (high temperature sintering-copper infiltration) to ensure product purity and accurate ratio, fine structure and excellent performance. Good arc breaking performance, good electrical conductivity, good thermal conductivity , the thermal expansion is small.

Please click below button for learn more our products.