Tecon Package Machinery Limited |

|

High Speed Cement Paper Bags Manufacturing Equipment with Deviation Rectifying System

Step1 High-speed Rotary Vacuum Feeding

Step2 Puncturing Vent Hole and Creasing

Step3 Tubes Delivery

Step4 Bottom-Opening

Step5 Valve Sheet Pasting

Step6 Automatic Gluing

Step7 Bottom-pasting and Bag Forming

Step8 Bottom Revising

Step9 Bags Counting and Palletizing

Step10 Programmable Logic Controller(PLC)

Technical parameters of our production line

HD4913 Bottomer Machine

Operating condition

Working hour | 22 hours/day |

Design temperature | 0~40℃ |

Design humidity | MAX. 95% |

Number required | 1 unit |

Model name | HD4913 |

Performance

Speed | 80~130 bags/min(Depends on paper quality, number of ply and operators’ skill.) |

Bag length | 520~880mm |

Bag width | 420~600 mm |

Bottom width | 90~130mm |

Bottom open width | 200~380mm |

Distance between bottom centers | 420~780mm |

Valve sheet length | 100~250mm |

Valve sheet width | 120~170mm |

Main drive motor | 33kw |

Total weight | 22.7T |

Size of whole set | 21.3m×2.3.m×1.8m ( L×W×H) |

Valve sheet reel diameter | Max.1,300mm |

Composing of the production line

HD4913 Bottomer Machine

Name | Quantity |

High speed feeder machine | 1 |

Perforation machine | 1 |

Tube opening unit | 1 |

Automatic gluing machine | 1 |

Scrip sealing machine | 1 |

Bag bottom turning unit | 1 |

Counting and delivery line | 1 |

Automatic delivering out unit | 1 |

Piling up platform | 1 |

Electric control unit | 1 (Schneider, German) |

Vacuum-pump | 1 (Schneider, German) |

1. Technical consultation

2. Detailed design of factory or workshop

3. Project evaluation

3. Training engineers and workers

4. Supplying spare part for long time

5. Installing and testing the whole production line

6. Good after-sale and in-sale servcie

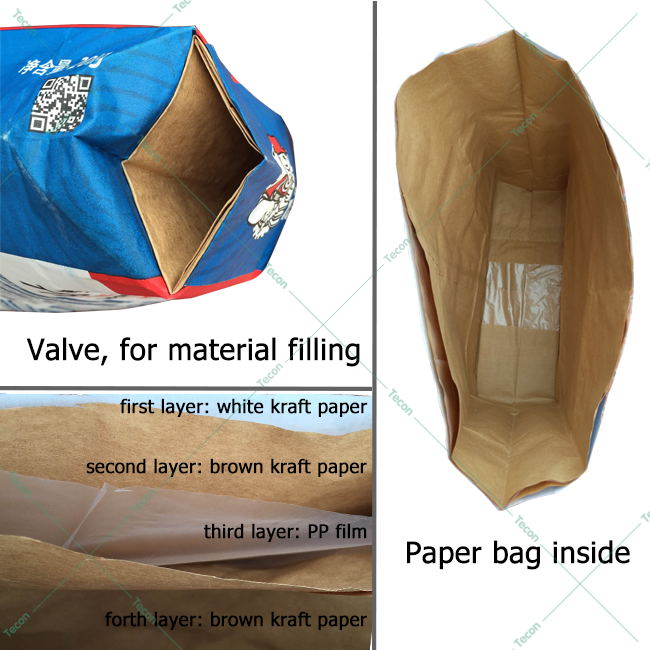

Sample Bags: