Product Description:

The Intelligent Automatic Bending Center has recently developed an

innovative new servo bending center. The products are developed

completely independently by each component: software drivers,

hardware circuits, and mechanical structures. This type of

automatic bending center is a high-end technology which has been

created specifically for the sheet metal industry.

The purpose of the product is to boost production efficiency,

reduce labor intensity, and enhance the company's image. This panel

bender has has been purchased numerous times by both domestic and

international markets, covering many ten industries. The

satisfaction of the customers has been overwhelming!

Features:

The bending center refers to the central position of the

deformation of the metal sheet during the metal bending process.

The determination of this position is very important for metal

processing, as it directly affects the size, shape, and accuracy of

the bent workpiece. When bending a metal sheet, it will bend around

the bending center, so the position of the bending center cannot be

determined arbitrarily. Usually, the bending center is located at

one-third of the material thickness.

The position of the bending center can be determined through

various methods such as experiments, such as simulation, drawing,

calculation, etc. When designing and manufacturing bending molds,

it is necessary to consider the position of the bending center to

ensure the quality of the bent workpiece.

Technical Parameters:

Item | Technical Parameters |

Max. bending speed | 0.2 second/time |

Max. bending width | 1400mm |

Max. bending hight | 170mm |

Rated voltage | 380v |

Motor total power | 34Kw |

Average power | about 1.5Kw |

Noise | about 50dB |

Machine size | 365* 190*290cm |

Total machine weight | about 10t |

Max. bending thickness (thicker panel customizable) | UST 5 1 5 N/ mm2 3 0 4 stainless steel 1 . 0 mm |

UST 4 1 0 N/ mm2 cold panel 1 . 2 mm |

UST 265N/ mm2 aluminum panel 1 . 6mm |

Minimum panel thickness | 0.35mm |

Four sides forming, minimum inner size | 140* 210mm |

Double sides forming minimum inner size | 140mm |

Max. bending size | 1400* 1400mm |

Axis QTY | standard synchronized 9 axises |

Hinge knife | common hinge knife |

Applications:

The Automatic Bending Center is a special designed high-performance

machine, which is made to maximize productivity and consequentially

minimize labor costs when it comes to sheet metal fabrication.

It’s application, not only in sheet metal fabrication, are

numerous; such as in cabinets(eg. file cabinets, tool cabinets,

outer guard covers, electrical cabinets, communication cabinets,

gas cabinets, water meter cabinets, etc..),

kitchenware(refrigerators, air conditioners, stoves, etc...),

furniture, ventilation, purification, door industry, decoration,

elevators and many other related metal forming fields.

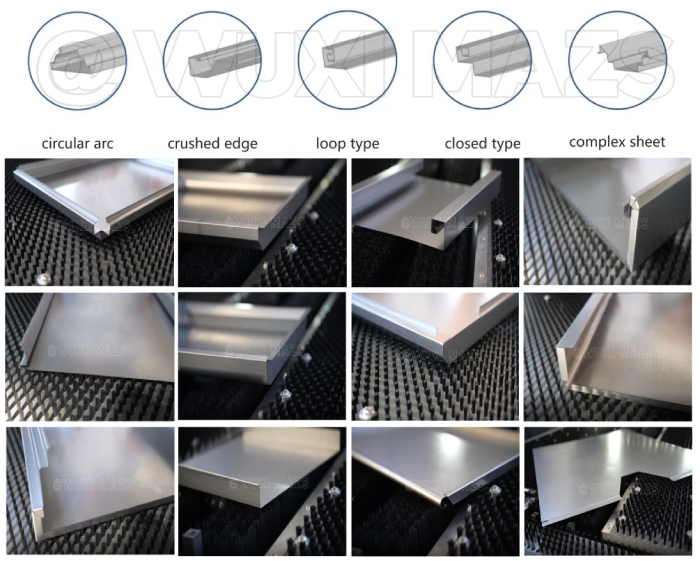

Bending Examples:

The intelligent flexible bending center uses universal bending

mold. Various shapes of bending can be achieved by use of one set

of mold. No need to make other customized molds.

It can easily achieve sheet metal bending requirements for circular

arc, crushed / pressed edge, loop shape, closed shape, and other

complex shapes.

Support and Services:

MAZS provides:

* Safe stock spare parts

Provide users with a complete inventory of accessories, ensure that

accessories and wearing parts are replaced in time, and escort

users' daily production.

* 7x24 Online service

Provide 7x24 hours of after-sales online services, maximize the

protection of user’s daily production plans, realizing worryfree

after-sale service.

* Lifetime service tracking

Establish a uniquely encoded user profile tracking and recording

the details of the operation of the device, and providing lifelong

maintenance services for cooperative users.

Packing and Shipping:

Packaging and Shipping for CNC Bending Machine:

* The CNC Bending Machine will be packed in wooden crates or cases.

* The package is designed to protect the machine from humidity and

physical damage during transportation.

* The packing will meet international shipping standard.

* The machine can be shipped by air, sea, truck, or train.

FAQ:

Q: What is the Brand Name of the Automatic Bending Center?

A: The Brand Name is MAZS.

Q: What is the Model Number of the Automatic Bending Center?

A: The Model Number is MAX-**09.

Q: Where is the Automatic Bending Center manufactured?

A: The Automatic Bending Center is manufactured in China.

Q: What certifications does the Automatic Bending Center have?

A: The Automatic Bending Center is certified by CE, ISO.

Q: What is the minimum order quantity for the Automatic Bending

Center?

A: The minimum order quantity is 1 set.