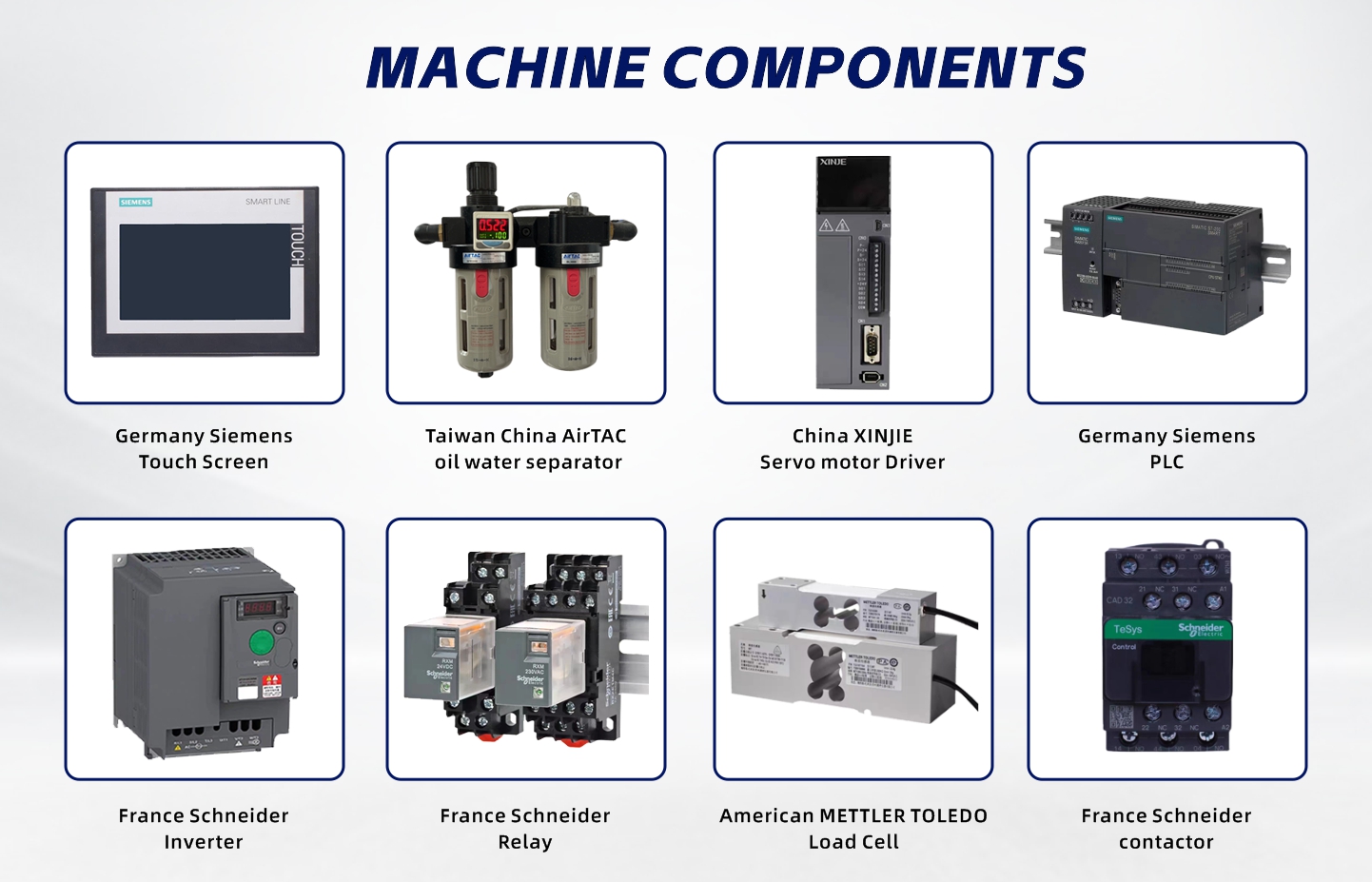

(1) The basic manufacturing principle of VPEKS is to use

international brands components as much as possible. Almost 95% to

100% components of them are made by OMRON>, SIEMENS>,

ABB>, Schnieder>, AirTAC>, NSK>, etc. In this case, our

foreign clients will have no worry about the lifespan and

replacement issue in the future. (2) In product design and program

design, we adhere to the principle of simplicity and ease of use.

After all, the purpose of automation is to save labor cost but not

to create operation cost.Q: What’s the main difference on service between VPEKS and other

manufacturers?

(1) Vpeks’ salesmen are not only sellers but also seasoned

engineers. They could help you a lot on providing best solution and

proper machines. (2) Vpeks provide integrated solution for clients.

Besides providing high quality machinery, in time online after-sale

service and on site installation service, we could help clients to

choose suitable package raw materials, calculate site area,

input-output ratio, electricity, air supply etc. Q: How to choose proper packing machine?

If you need packing machines for small bags, firstly please confirm

your bag type.Secondly, according your product’s characteristic to

choose dosing system(screw type, pump type, etc). Thirdly,

according to bag size choose machine model. If you need packing

machine for big bags(5kg to 50kg), just tell us your target output

per hour and the name of your raw materials.

Q: How to choose proper automatic palletizing machine?

Please tell us the pallet size, target output( bags/hour). We will

recommend most suitable model to you.

Q: How long does it usually take to receive the equipment? The production time of different machines ranges from 10 days to

30 working days. As for shipping issue, there are different

shipping ways for options. For most countries, we could help

clients to do Door to Door shipping service. Air shipping is fast

but expensive,it’s a good choice for urgent orders, it only takes

7-10 days max. Sea shipping is the most economical shipping way,

depending on different destination seaports, the shipping times

ranges from 15 to 45 days.

Q: What’s the guarantee of the machine?

We have 1 year guarantee for all the machines. If any components is

broken during 1 year, we will send replacement to clients for free

by express. And we will take videos to teach you how to replace it.

Also we have several service center in different countries. We

offer lifetime technical support. Since we adopts international

components, clients are easy to source spare parts from local after

1 year. Q: How will my machines be installed if necessary? How long does

the installation take?

We’ll dispatch an engineer to your facility, help to install the

machine and train your staff on how to operate it. The customer

pays for round trip airfare, accommodation and USD150/day/person.

Depending on the machines you ordered, it will which takes about 7

to 30 days.

Q: Do you have any reference?

We have customer success cases in most countries. Suppose we get

permission from a customer who imports a machine from us.

Q: What is the packing speed of the machine? The actual speed may be influenced by factors as follows:

Material: viscosity, density, volume, weight, etc. Machine: the

speed of the dosing system (piston for liquid, combination scale

for granules and augur filler for powder)

Q: Do you have certificates?

We have been certified by reputable certification bodies.

Q: How do i test the machine before shipping?

Once the machine is finished, we will run over 72 hours and send

test video to you. Of course, you can come in person or hire a

third-party organization to inspect our factory.

Q: What is your terms of payment ? Payment<=5000USD, 100% in advance. Payment>=5000USD, 30% T/T

in advance ,balance before shipment.