Shenzhen Yuzhou Machinery Equipment Co., Ltd |

|

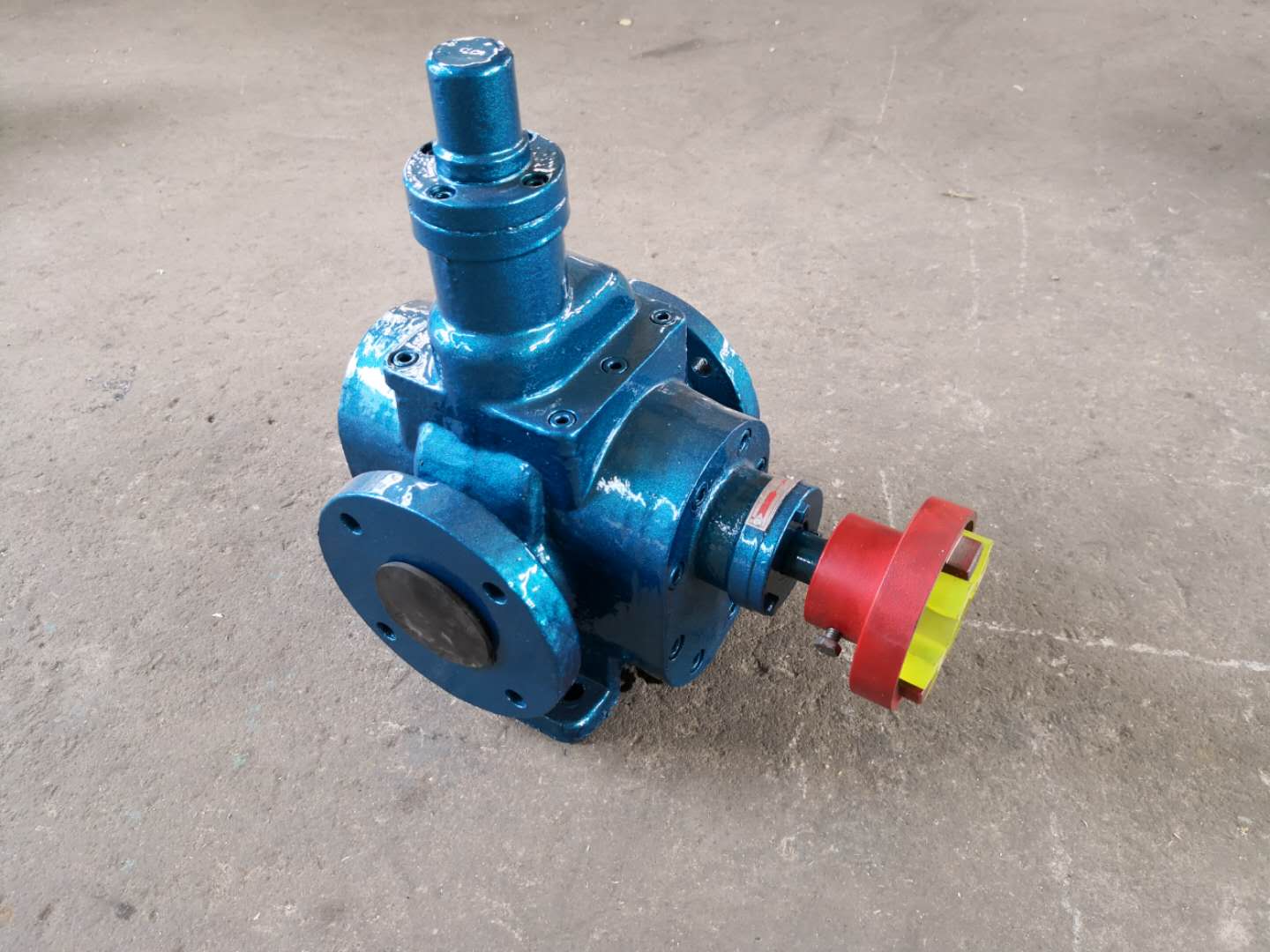

YCB series bare pump gear oil transfer pump cast iron and stainless

steel material

Application:

YCB series circular gear pump applies to delivering non-corrosive

lubricating-oil or equivalent liquid without solid particles and

fibres at temperature below 300℃ and with the viscosity of

5-1500cSt.

It applies to hydraulic system, too.

Reducing the speed, the pump can delivery the liquid that the

viscosity can be up to 500000cSt.

Application Scope:

Advantages:

Technical Parameters:

| Model | Flow (m3/h) | Presure (Mpa) | Rev (r/min) | Npshr (m) | Frequency (hz) |

| YCB0.6-0.6 | 0.6 1.0 0.7 1.2 | 0.6 | 910 1390 1130 1710 | 5.5 | 50 50 60 60 |

| YCB0.6-1.6 | 0.6 1.0 0.7 1.2 | 1.6 | 910 1400 1130 1710 | 7.0 | 50 50 60 60 |

| YCB1.6-0.6 | 1.6 2.5 1.9 3.0 | 0.6 | 910 1400 1130 1710 | 5.5 | 50 50 60 60 |

| YCB1.6-1.6 | 1.6 2.5 1.9 3.0 | 1.6 | 940 1440 1150 1750 | 7.0 | 50 50 60 60 |

| YCB3.3-0.6 | 3.3 5.0 4.0 6.0 | 0.6 | 940 1420 1150 1730 | 5.0 | 50 50 60 60 |

| YCB3.3-1.6 | 3.3 5.0 4.0 6.0 | 1.6 | 960 1440 1170 1750 | 7.0 | 50 50 60 60 |

| YCB4-0.6 | 4.0 6.0 4.8 7.2 | 0.6 | 940 1420 1150 1730

| 5.0 | 50 50 60 60 |

| YCB4-1.6 | 4.0 6.0 4.8 7.2 | 1.6 | 960 1440 1170 1750 | 7.0 | 50 50 60 60 |

| YCB8-0.6 | 8.0 12.0 9.6 14.4 | 0.6 | 960 1440 1170 1750 | 5.0 | 50 50 60 60 |

| YCB8-1.6 | 8.0 12.0 9.6 14.4 | 1.6 | 970 1460 1170 1760 | 7.0 | 50 50 60 60 |

Troubles and Solutions

| Troubles | Productive Reason |

Solutions

|

| Discharging oil or discharging little oil | 1.Revolving direction reversed 2.Valve closed 3.Oil absorption tube has not been soaked into the oil 4.The high of absorption exceeds the rated 5.The filtering area of the filter at absorption end is too small 6.Air leakage in absorption tube 7.Safety valve blocked or doesn’t work well 8. Lower temperature of oil results in viscosity increasing | 1.Change in to right direction 2.Open valve 3.Check out oil absorption tube and soak it in the liquid 4.Measure absorption pressure and raise the oil level 5.Change filter and extend the filtering area6.Check every joint and seal them with sealing material 7.Disassemble and wash safety valve and polish with abrasive grease 8. Heat liquid or reduce exhausting pressure or the volume of oil exhaustion |

| No pressure or pressure not rising | 1.The button of the pressure meter is still in OFF position 2.The pressure of the safety valve is too low3.Side tube valve is on 4.High temperature,low viscosity o foil and small resistance of the tube 5.Air leakage in the tube | 1.Press the button ON of the pressure meter2.Readjust the safety valve pressure 3.Close the side tube valve 4.Reduce oil temperature 5. Check out absorption tube |

| Oil leakage in mechanical seal | 1.Shaft seal has not been adjusted properly 2.O-seal ring wear 3.The defects caused by wearing of stationary and rotating rings of mechanical seal4.Spring flabby | 1.Adjust it 2.Change O-seal 3.Change stationary and rotating rings or polish the magain4.Change spring |

| Noise and vibration | 1.Improper assembling 2.The in concentricity of pump shaft and motor shaft 3.Absorption tube or filter stopped up 4.Absorption tube dimension is too small and long.It could not pump in,for resistance is too big 5.Oil exhaustion tube’s resistance is too big6.Air leakage 7.Fastener is relaxed 8.Gears and bearings stand sides show serious wear and tear or gripped | 1.Check out and maintain 2.adjust it 3.Clear dirt things in the absorption tube or filter 4.Read just it 5.Check up whether exhaustion tube or valve are stopped up6.Check up and maintain7.Check up and tighten it 8.Disassemble and maintain or change them |

| Safely valve unworkable | 1.Wrong position2.Pressure too high 3.Safety valve chip gripped | 1.Reassembling it2.Lower the pressure 3.Disassembling,wash and adjust |