Shangqiu Sihai Energy Technology Co., Ltd. |

|

Verified Suppliers

|

|

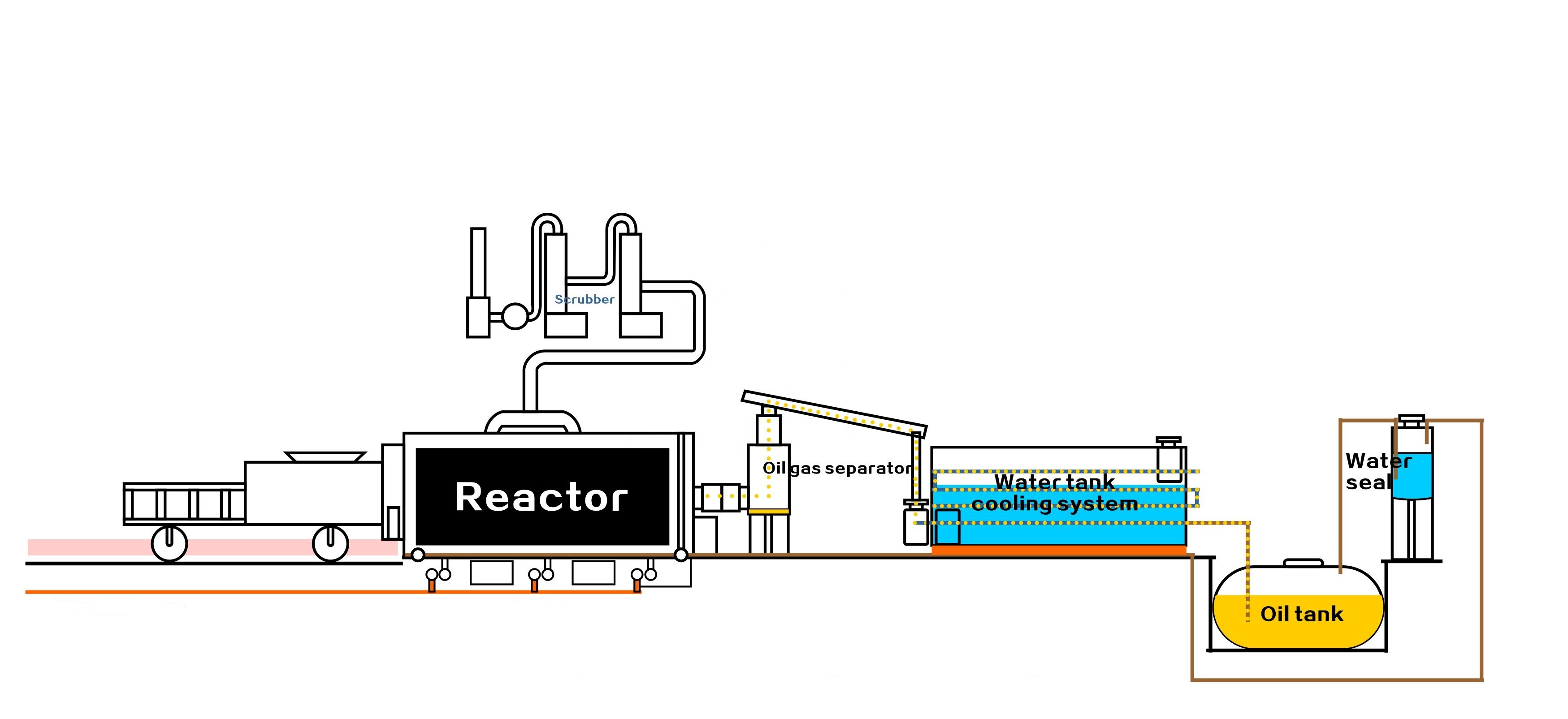

Model:LJ-12

Raw

material:Waste tire, waste plastic, waste rubber

Structure:Horizontal

24hours processing capacity:12tons raw

materials

24hours oil output:5.4 tons fuel oil

Work pressure:Atmospheric

Host speed:0.4rmin

Power:17.5KW

Cooling:Water cooling

Lose water(TH):8

Transport:External gear drive

Heating

method:Directly

Installation:Foundation

Noise dB(A):≤85

Reactor size length*wideth:2800x6600

Working form:batch

Weight of Reactor(T):36

Manufacuring time:20days

a. Waste gas: Transferred through two safety device: water close

&burning air nozzle. Fully burnt, not only eliminated pollutant

but also minimized the quantity of fuels. For smoke dust discharge,

we apply series machines of patent in our company Desulphurization

and dust remover which could control the smoke dust discharge

amount meet relative standards of GB-2001.

b. Waste liquid: Produced waste acidic water in the process of oil

disposing (50kg process from 1 ton of oil easy to process for small

quantity). counteract the liquid by alkalescent liquid solution.

After three stage of filtration, the litmusless wa ste water was

introduced to evaporator(use the heat of the flue of main processor

as its heating resource)

c. Waste solid. The solid residua will be left after the catalyst

splitting from scrap plastic, approximately composes the waste

plastic weight about 5% to 10%. Its main component is the thick

black carbon. It can be the raw material of the production industry

of black carbon. Also could be mixed with the pulverized coal ash

which produces for the raw material thermal power plant, also could

be the raw material of manufacture pulverized coal ash brick (one

kind of environmental protection building material).

Model | Raw material | Structure form | Cooling system |

LJ-12 | Waste tire, plastic,rubber | Horizontal | Water cooling |

Heating method | oil output rate | Power | Installation |

Directly | 45% | 17.5KW | Foundation |

1, To improve the quality and functions of products is our purpose, customer's satisfaction is our principle.

2, With fast and practical feed and slag system.

Efficient gas heating system.

3, stable product quality , supply, the lifetime after sale.