Chongqing HLA Mechanical Equipment Co., Ltd. |

|

Verified Suppliers

|

|

4 Kw Diesel Light Lubricating Oil Purifier With PLC Programmable Controller

Application:

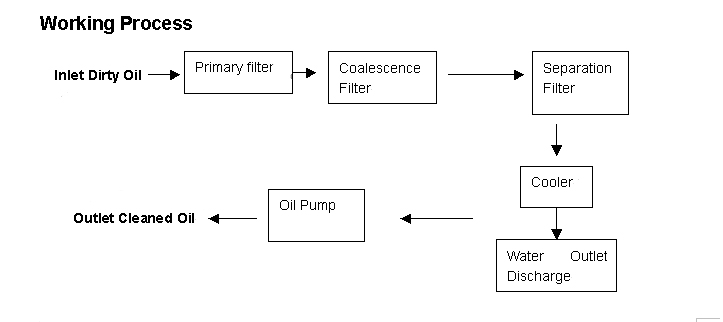

DSP Coalescence-separation oil purifier is designed to remove free water and dissolved water from lube oils or diesel fuel,coalescing filter will make the free and dissolved water from small molecule to big drop, then separation filter remove the water drop by gravity, falling into the water tank. It removes the particles by stages of filters and cleanness up to NAS grade 6. It is applicable for on line running with light oil filled, turbine oil filled and lubricating oil filled systems, especially good for water- leakage systems.

According to the requirements of the clients', we recommended the coalescence separation oil filtration car to purify the oil in the system. In the hydraulic lube oil system ,moisture existing in oil liquid will lead to oxidation so as to make oil deteriorated, reducing the thickness of the lubricating oil,causing oil liquid polymerization to form large molecules so as to change oil viscosity, which forms the organic acid and corrodes the surface of the metal, the parameter of lubricating oil will be changed or lose.In the traditional filter and separation machine,it is very hard to remove one kind of liquid from the other liquid. The Coalescence Separation oil filtration equipment researched by our company has the function of high precision filtration and efficient dehydration, removing the particles, emulsion water and free water effectively. It is has a excellent effect in the oil which existing heavy moisture, the separation rate is several fold or decade fold of the traditional ones.

Features:

1. DSP Series Purifier adopt special oil water separator which requires no heating offering more than 20 times dehydrating efficiency over other types of purifier.

2. As no heating is needed, the additives in the oil are well prevented from degradation or deterioration.

3. Easy-to-operate, water can be discharged online automatically without manual operation.

4. Low operation cost, 20%-40% lower than vacuum purifier, centrifugal purifier and filter press.

5. DSP Series Purifier involves in sophisticated filtration, efficient dehydration and vacuum evaporation and automation as well.

6. Rapidly removing large amount free & emulsified water from

Oil and water content reach 100 PPM.

7. The coalesced oil takes the least restricted path to exit and

rises or floats through the media to the top of the bulk liquid

surface.

8. The working conditions of all the parts are displayed clearly,

monitoring, alarming, action control and safety stop enable the oil

purifier machine to run online

9. In the way of automatic control,using highly reliable PLC programmable controller and non-electricity detection technology, which can effectively detect a variety of equipment working conditions, with automatic operation, intelligent temperature control, pressure protection, anti-operation and other functions; Perfect self-test function of the system, strong anti-interference ability, and set up RS232 communication interface, to facilitate computer networking in order to achieve remote maintenance and control; Preset up hand-held remote control interface that allows unattended.

Particles filtration system:

It constitutes of adsorption filter elements in front of the pump (80 holes),pre filter (20micro),high efficiency filter(5micro).The high precision filter elements choose the imported Lydall material which has the feature of high precision, large pollution capacity and long service life.

Coalescence hydroextraction system:

It constitutes of tank, coalescence, separation. The tank adopts the flange structure. Coalescence filter elements adopts the unique polar molecule structure,the free water and the emulsify water that runs through the elements form the big drops by coalescence and set down to the tank. Separation filter elements are made in special hydrophobic materials .When the oil liquid runs through the filter elements, the water is rebelled out of the outer surface and drop into the water tank according to the coalescence and gravity.

Oil pump:

The oil pump adopts the internal circle gear pump so as to get the function of low noise, high suction and working steadily.

Technical Specification

| Model | DSP200 | |

| Capacity(L/min) | 200 | |

| Working pressure | ≤ 0.4 Mpa | |

| Filtering precision | ≤1 micron | |

| Water content | ≤100 ppm | |

| Cleanness level | NAS 6 grade | |

| Continuous work | ≥200 hr | |

| No failure running | ≥5000 hr | |

| Power supply | 380V, 50HZ, 3PH ( or Customized ) | |

| Working noise | 65 dB | |

| Total power (kw) | 4 | |

| Inlet/outlet(mm) | 58 | |

| Weight (kg) | 900 | |

Dimension (mm) | L | 1650 |

| W | 1100 | |

| H | 1750 | |

Device constitution and technology features:

The machine is integrated movable device which are settled in one panel, including the filtration system, inlet and outlet pipe connector, oil level indicator, high pressure protection device, pressure gauge and so on. It can remove the moisture particles, demulsification to confirm the recycling of the lubricating oil and healthy work of the device continuously.

When inspection, it should drain all the oil liquid in the machine, and choose the function of filtration or filtration + dehydration.

There is a exit for taking sample in the outlet in the oil filtration machine so as to get the sample.

Oil filtration and dehydration system:

This machine has three steps filter, which is suction oil filter (80 holes), pre filter (20 micro), high efficiency filter (5 micro). It can be controlled in the requirements of the system of the purify degree according to the three steps to make sure the purify degree of the oil liquid. The machine has the coalescence and dehydration system in the coalescence technology according to the feature of turbine oil and different surface tension for a high efficiency dehydration system, especially for the moisture in the oil liquid. It has the advantages that the vacuum and centrifuging can not reach. It will not change the physical feature and chemical features, prolong the working life of the oil liquid.

Auto controlling system:

It can warn the differential pressure, indicate the level in the tank, and high load of the pump and motor.

Material:

The machine shell and pipe system are made of the low content alloy high quality cast steel , the pump adopts the corrosive proof and rust prevention cast steel, and the frame adopts the cast steel.

Machine performance:

The oil liquid reach a index as following according this oil filtration device:

Precision: 5μm

Pollution degree: Class 6 in NAS1638

Existing moisture: Lower than 100ppm