Taikang Yinyu Boiler Manufacturing Co., Ltd |

|

1t No Pollution High Efficiency Fully Automatic Electric Heating Steam Boiler

Electric heated steam boiler is our industrial field, is relatively

common, because of its use environment is different, as well

as its many types, so it is used, generally need to be based

on the specific type of product and performance to

determine the use of the occasion, at the same time, the

different products work on the principle is also different, in

order to better understand the product, we will then analyze

how it works.

Principle: heating equipment (burner) release heat, first

through radiation heat transfer by the water-cooled wall

absorption, water-cooled wall boiling vaporization, producing

a large amount of steam into the steam package for soda

separation (except DC furnace), separated saturated steam

into the superheater, through radiation, convection mode to

continue to absorb the top of the furnace and horizontal flue,

tail flue flue smoke heat, and make the superheated steam to

the required operating temperature. Usually also set up a

reheater, is used to heat the steam after the high-pressure

cylinder work, reheater out of the reheat steam and then to

the medium and low-pressure cylinder to continue to do

power generation. In layman's way, an electric heated steam

boiler is a device that absorbs the heat from fuel combustion

and turns water into steam with certain parameters (such as

pressure, temperature, etc.).

Electric heated steam boiler is a kind of energy conversion

equipment, the energy input to the boiler has the chemical

energy, electric energy, high temperature flue gas heat and

other forms, and after the boiler conversion, the outward

output of steam with a certain amount of heat energy, high

temperature water or organic heat carrier. The original

meaning of a pot refers to a water container heated on a fire,

a furnace refers to a place where fuel is burned, and a boiler

comprises two parts of the pot and the furnace. The pot is

used to fill the metal container of water, the furnace is the

fuel burning part, the water in the pot absorbs the heat of

fuel combustion in the furnace and turns into steam, the

basic principle is similar to boiling water, the pot is

equivalent to a kettle, the stove is equivalent to a stove. The

hot water or steam produced in the boiler can provide the

heat required directly for industrial production and people's

lives, or it can be converted to mechanical energy by steam

power installation, or then by a generator. Boilers that

provide hot water are called hot water boilers and are mainly

used for life, and there are also a few applications in

industrial production. The boiler that produces steam is

called the electric heated steam boiler, often referred to as

the boiler, and is mostly used in thermal power stations,

ships, locomotives and industrial and mining enterprises.

A boiler is a thermal device that uses heat released by fuel

combustion or residual heat from industrial production to

transfer water to the water in a container, bringing water to

the desired temperature (hot water) or a certain pressure

vapor. It is by the "pot" (i.e. the boiler body water pressure

part, heat-absorbing part called the pot), the furnace by the

hot surface of the knotted slag serious problems. Generally

can reduce the exhaust temperature of 4 to 12 degrees,

improve the main, reheat steam temperature of 0.5 to 5

degrees, reduce the mechanical and electrical consumption

of the wind, and can early detection of creep, corrosion and

other hidden dangers, the safety of the unit, economic

operation is very helpful.

Electric heated steam boiler work principle is generally after a

certain conversion, therefore, different products, its

conversion form is different, so say, we choose the product,

or choose to suit us, because of different products, its use of

the field is also different, so we use, we must pay special

attention to the use.

WDR1-0.7

| NO; | Name | Unit | Number | Description |

| 1 | Rated output | t/h | 1 | |

| 2 | Rated working power | Mpa | 0.7 | |

| 3 | Rated steam pressure | ℃ | 170 | |

| 4 | Heating efficiency | % | 99 | |

| 5 | Output diameter | mm | DN50 | |

| 6 | Design fuels | / | Electric | |

| 7 | Safety valve diameter | mm | DN40 | |

| 8 | Bulk size | mm | 3420×1760×1930 |

Pre-sale service:

We help customer choose the best boiler model according to

different requirements of various industry. Before delivery we

will provide foundation drawing, layout drawing, boiler room

layout, etc.

In-sale service:

We keep 24 hours online and keep close contacts during the

production process to ensure on time delivery with perfect

finished product.

After-sale service:

1.provide full range of original spare parts.

2.Engineers abroad installation and commissioning service is

available.

3.Our engineers will held a training for boiler workers to

ensure the safe operation.

4.Free maintenance and repair for one year and lifelong

service.

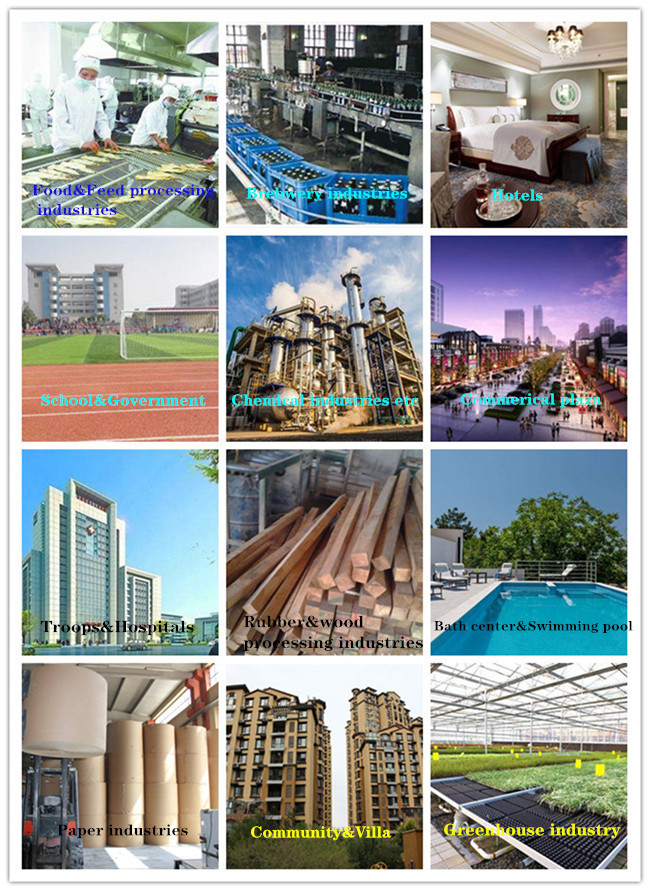

Boiler application areas