Active Member

|

[China]

Address: #13 West of Zhen`an Road, Chang An Town, Dong Guan City, Guang Dong Province, China

Contact name:jeff

KYE Mould Techenology Limited |

|

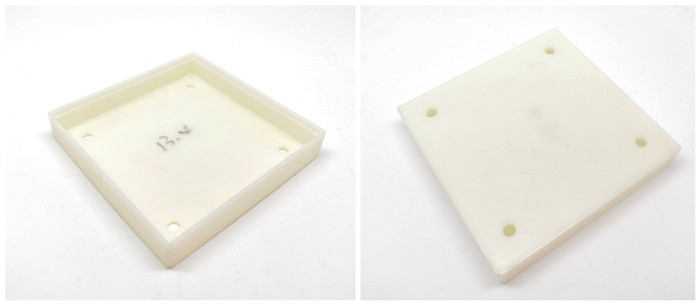

2 Plate Full Hardened S50C LKM Plastic Injection Mold

Product Details Description

Application | Auto Parts, Home Appliance, Medica Equipment, Household Product,

Electronical Parts, etc. | |||

Mold Base | LKM, HASCO, DME, etc. | |||

Mold Steel | NAK80, ASSAB8407, S136, 718H, 738H, etc. | |||

Mold Cavity | Single cavity mold or Multi cavities mold | |||

Tolerance | +/-0.002mm | |||

Finish | Polish, Silk Screen, Painting, etc. | |||

Sprue Gate | Hot runner, Cold runner, Tunnel gate, Pin point gate, sub-gate,

etc. | |||

Product Resin | PC, ABS, PP, POM, PBT, NYLON, PMMA, TPE, TPU, SAN, etc. | |||

Mold Life | 500,000-1,000,000 shots | |||

T0 Lead Time | 30 days - 45 days | |||

Package | Artificial wooden box | |||

Ship Condition | Ex work, FOB or to be negotiated | |||

KYE team is at your service offering professional expertise, flexibility and accuracy in assumed deadlines.We are able to offer the full range of service from mold designing, making, plastic part molding to printing, assembly, package, and shipping arrangement

This are the objective to arrive together with success to the target.Welcome your visit!

What KYE can offer

1. Engineering/ Technical

Mold design

Mold flow analysis

Project management

Supplier Managed Inventory

Design for Manufacturing

2. Mold Building

Mold up range from samll, middle and large

Complex Surfaces

Assembly Fixtures

Hot-Runner Capability

3. Technical Injection Molding

Structural Foam

Small Precision and Large Cosmetic

High Pressure Thin wall

Robotic and Automated Pick and Place

4. Plasting/die-casting molding

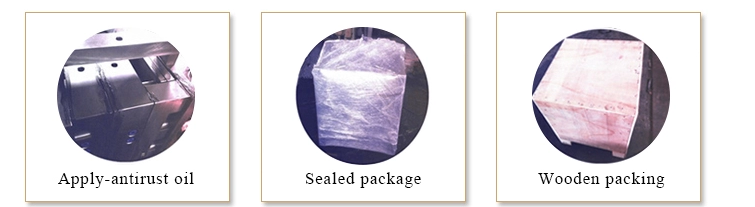

Packing and delivery

We will pack the mould according to the shipping way, different packaging details for sea, air and land transportation. All the mould components are provided and packed in separated box with clear makring. Plastic samples provided, Toolbook provided.

OUR ADVANTAGE

What we can do for you

1. We are a specialized plastic manufactory and design different plastic molds

2. Strict Plastic injection process

3. Different plastic materials,different colors,different shapes plastic injection products

4. If you have any new item need to be made,please contact with us.We can do our best to change your idea into real products.RAQ

Q1: Are you a factory or trade company?

We are direct factory with 10 experienced engineers and approximate 2,000 square meters workshop area.

Q2: What kind of service do you provide?

We can offer mould making, die casting, CNC machining, stamping, Plastics injection moulding, assembly and various metal surface treatment.

Q3: How long should we take for a quotation?

After receiving detail information we will quote within 2 days.

Q4: I have no 3D drawing, how should I start the new project?

You can supply us a sample, we will help you finish the 3D drawing design.

Q5: How long is the lead-time for mold?

Normally, the lead time is 4-5 weeks after the mold 3D drawing was approved.It all depends on the mold’s size and complexity.

Q6: Is it possible to know how's product going on without visiting your company?

We will offer the mold process schedule with digital pictures and videos each week.

Q7: Before shipment, how to make sure the products quality?

If you don't come to our factory and also don't have the third party for inspection, we will supply you a video for production process detail include process report, products size,structure and surface detail, packing detail and so on, and will provide the inspection report to you.