Henan Dongfang Noodle Machine Group Co., Ltd. |

|

Verified Suppliers

|

Automatic Extruded Instant Noodle Production Line

Extruded instant noodle making machine is latest design by our engineers.

It also has the largest production capacity in China, with high degree of automation.

Technological Process of Noodle Production Line

Brine water mixing and measuring---Dough mixing---Ripen conveying---Extruding and cutting---distributiong and automatic into noodle tray---Drying---Packaging

Technological Process of Extruded Noodle Production Line

1 Output Capacity: 12,000 pieces/hour,

2 Cake weight: 80grams can be customized;

3 Shape of the noodle piece: round , square;

4 Dough mixing time: about 15 minutes;

5 Drying temperature ≤ 55°C

6 Voltage: 3phase 380V, 50 Hz can be customized;

Advantage of extruded noodle production line:

NOODLE MAKING EQUIPMENT INTRODUCTION DESCROPTION

Brine water mixing tank

Dough mixing

Extruding and cutting

Distributiong and automatic into noodle tray

Drying Machine

Control panels

Packing and delivery

Installation and commission

1. Expenses of Visa paid by THE BUYER.

2. Medical treatment insurance premium and “injuries or deaths”insurance premium for the service technicians’ Accidental Injury during their installation service period should be paid by THE BUYER

3. Expenses of engineers in china paid by the Sellers.

4. Expenses of during installation paid by the Buyers.120USD/DAY(the day form engineers get boarding in china to boarding in Buyers country after installation.)

5. The Buyers should pay engineers room and board during installation, and international air tickets.

6. If the buyer do not have enough necessary installation condition, all the expense of technicians who need go again should be paid by buyer as the above terms, and the schedule should be arranged by seller.

After-sale Service Regulation (Policy) for Overseas Customers

1. Guarantee Period

All of the NOODLE PRODUCTION LINE (hereinafter called as Machine) made by Henan Dongfang Noodle Machine Group Co.,Ltd has one year (365 days)Quality Guarantee Period. The date would be calculated from the date of machine operation or 15 Month from the date of sea shipment (the Date of its B/L).

2. The Wearing parts of the Machine:

If the customer inform us that some Wearing parts is required,

we could arrange to send to air mailing within 7 working days.

All the expenses should be paid through T/T in advance at customers' cost first.

3. the machine stoppage:

If the machine could not be operated and

need our technical person to Customers' country,

Customer should assist our technical person to get the Visa first and to purchase return ticket for the technician at customers' cost first.

the technician should arrive customers' airport as per Customer’s ticket schedule.

4.If it's found that the problem (stoppage) was happened due to our quality

or manufacturing problem,

The expenses of parts, mailing charge, airline tickets would be refunded

to our customer.

It would be excepted if the stoppage was happened due to the misoperation from

Customer side.

5. Customer should pay technician salary USD 120 per day for each person

If the steppage happened due to the misoperation from Customer side.

Customer should not pay technician any salary If the steppage happened due to the Machine’s quality or manufacturing problem.

The expenses of our technician in customer country should be at our customer's expenses, which would include local transportation, food, housing, and Accidental Insurance

Company Information

Customer Show

Some Cooperative Client

Our fully automatic instant noodles production lineshave covered

over 70% of the sales market in China, reaching over 80 countries

and regions in the world, winning approvals among customers both at

home and abroad.

Dongfang is determined to be the leader of noodle machine industry

in the world! Our Service includes: pre-sale service, Installation

And Commissioning And The Acceptance, Technical Information,

After-sales, Warranty And Technical Service, etc.

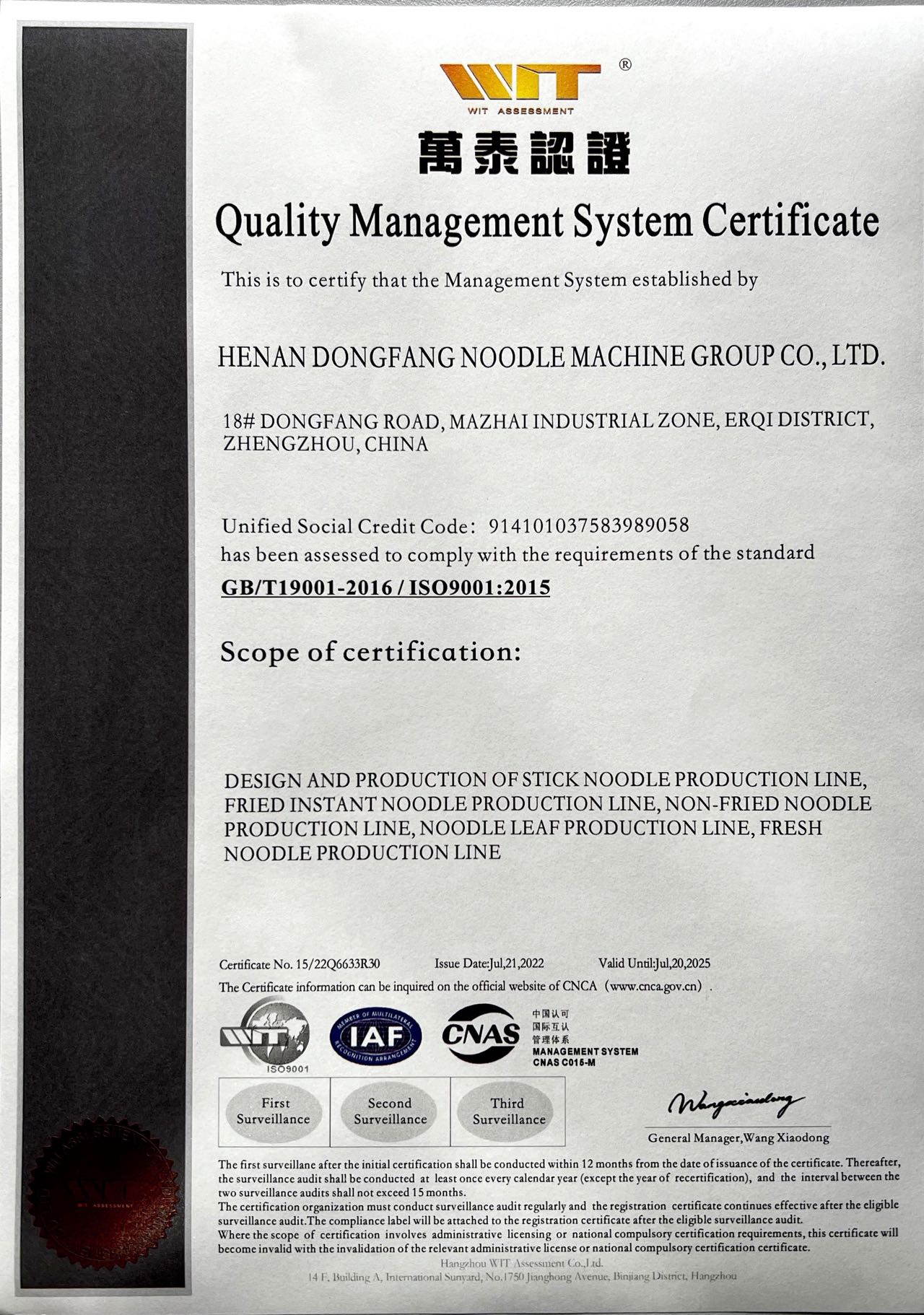

Our Certificate

Henan Dongfang Noodle Machine Group Co.,Ltd. Established in 1975,

specializes in the design, manufacture and marketing of various

fully automatic noodle production lines.

Fried Instant Noodle and Non-fried Instant Noodle, stick noodle,

chowmein noodle, extruded noodle, semi-dried noodle, fresh noodle,

rippen fresh noodle..etc

With 150,000 square meters standardized factory building area and

over 600 highly qualified employees , has passed ISO9001

certification and CE international standard certification, more

than 40 innovative products have obtained the invention or utility

model national patents, had exported to 80 countries.

Over the recent 30 years, through close cooperation with domestic

universities and research institutions, the company has filled up

many blanks in food machinery industry in China, winning dozens of

awards, such as “National Prize for Progress in Science and

Technology”,“National Prize for New Products”, “First Prize of

National High-Tech, Energy-Saving Products” etc

Contact

Sales director: Annie Wang

INTERNATIONAL SALES HOTLINE: +86-13838362606

Mobile /Whatsapp/wechat No: +86-13838362606

Email: eastgroup.sales@gmail.com

Address: 18# dongfang road, mazhai industrial park, zhengzhou city,

China.

HENAN DONGFANG NOODLE MACHINE GROUP CO.,LTD