Eternal Bliss Alloy Casting & Forging Co.,LTD. |

|

![]()

Mo-Re 10 Alloy Steel Cast Sleeves

Mo-Re Alloy can be used for heat treating,refineries,steel production,petrochemical applications and aerospace industries.

Outstanding Features:

1. We use Spetrometer to control the chemlcal elements;

2. We check the matrix structure with our mlcroscope;

3. We can do fully machining on the sleeve parts.

4. We adopt Centrifugal Cast process with higher efficiency to shortening the process time;

5. Production Process: centrifugal cast process + machining process

7. We can make the cast sleeves as per customer design.

8. Diameter: 50mm - 500mm; Length: less than 400mm.

9. Material grades:

| ASTM | Alloy | C | Cr | Ni | Other | Description |

| 30/50 W | 22H® | 0.45 | 30 | 50 | W 4 | The alloy is wholly austenitic and is intended for use at elevated temperatures up to 2200° F (1204° C). |

| HP+W | MO-RE®1 | 0.45 | 25 | 35 | W 1.5 | Tungsten addition increases creep strength. Useful to 2000°/2100° F (1093°/1149°C). MO-RE® 1 is a good option for use in severe high temperature furnace roll and radiant tube applications. |

| 28/48 W+Co | Super 22H® | 0.45 | 28 | 48 | W 5 Co 3 | Alloy of choice for extreme high temperature service to 2200° F (1066° to 1200° C). |

| MO-RE®2 | 0.2 | 33 | 50 | W 17+Al | Exceptional strength and oxidation resistance to 2400° F (1315° C). | |

| HP Nb LC | MO-RE®9 | 0.09 | 25 | 35 | Nb 1 | MO-RE ® 9 is used primarily for parts located outside of furnace such as transfer lines and headers. It is designed for applications which require high ductility after aging. |

| A608 | MO-RE ®10 | 0.4 | 25 | 35 | Nb 1.2 | MO-RE ®10 is a fully austenitic alloy with controlled additions of columbium (niobium) for ethylene pyrolysis tubing. It has improved high temperature strength and resistance to carburization and oxidation up to 2000° F (1093° C). |

| HP+Nb+MA | MO-RE ®10 MA | 0.45 | 25 | 35 | Nb 1.2 Ti Rare Earths | MO-RE ®10 MA is microalloyed with additions of columbium (niobium), zirconium and titanium for improved high temperature strength and resistance to carburization and oxidation up to 1975 °F (1079 °C). Microalloying produces fine, stable carbides which retard dislocation movement, thereby increasing elevated temperature strength and creep resistance. Intended for ethylene pyrolysis applications. |

| A297 A351 | MO-RE ®21 | 0.1 | 20 | 32 | Nb 1.2 | Low carbon, columbium strengthened alloy with excellent thermal fatigue / thermal shock resistance. MO-RE 21 is a cast alternative to wrought alloy 800HT. |

| MO-RE ®35 MA | 0.45 | 28 | 36 | Al, Rare Earths | MO-RE ® 35 MA is a fully austenitic heat resistant alloy developed by Duraloy primarily for plate heat treating furnace roll applications. MO-RE ®35 MA is microalloyed with additions of aluminum, titanium and proprietary rare earth additions for improved creep strength at furnace operating temperatures. Microalloying produces fine, stable carbides which retard dislocation movement, thereby increasing elevated temperature strength and creep resistance. Primarily intended for use in plate furnace rolls. | |

| 35/45 Nb+MA | MO-RE® 40 MA | 0.45 | 34 | 45 | Nb 1 Ti Rare Earths | MO-RE ®40MA has exceptional resistance to carburization and oxidation up to 2100 °F (1149 °C). |

| MO-RE ®49 | 0.4 | 23 | 5 | MO-RE ®49 is an iron-chromium-nickel heat resistant alloy developed for aerospace tooling. | ||

| MO-RE® 2150 | These Cr-Ni-W alloys are produced to unique chemistries for each customer to work in their dry tunnel furnace roll application. | |||||

| A1002 | Nickel Aluminide | R&D 100 Award Winner Nickel-Aluminum alloy, developed and patented by Oak Ridge National Laboratory and licensed to Duraloy. Alloy shows exceptional resistance to creep at elevated temperatures. Also shows strong resistance to carburization in service. Excellent selection for plate hardening furnace rolls. | ||||

| SUPERTHERM® | 0.45 | 25 | 35 | Co 15 W 5 | Supertherm exhibits excellent oxidation resistance & high temperature strength to 2300° F (1260 °C). Supertherm is an excellent alloy for use in high temperature press platens or other applications where high temperature strength is critical. | |

| TMA®4505 | 0.3 | 20 | 25 | W, Nb additons | TMA ®4505 is a heat resistant alloy developed by Duraloy for SuperPlastic and Hot Press tooling applications. It is a modification of ASTM A297 Grade HN with improved properties. | |

| HK-40+MA | TMA®4700 | 0.4 | 25 | 20 | W, Nb & Ti additions | TMA®4700 is an iron-chromium-nickel (modified HK type) heat resistant alloy. TMA ®4700 is microalloyed with additions of columbium (niobium), tungsten, titanium and rare earths for superior stress rupture properties to 2000°F (1093°C). Microalloying produces fine, stable carbides which retard dislocation movement, thereby increasing elevated temperature strength and creep resistance. |

| TMA®4701 | R&D 100 Award Winner heat resistant alloy developed by Duraloy. TMA®-nickel (modified HK type). TMA® 4701 has a proprietary, microalloyed, computer designed chemistry which gives the alloy better high temperature creep properties than similar alloys. It is intended primarily for reforming applications. | |||||

| HP+Nb+MA (LoSil) | TMA®6300 | 0.4 | 25 | 35 | Nb 1.2 Ti Rare Earths | TMA® 6300 is a fully austenitic heat resistant alloy. TMA®6300 is microalloyed with additions of columbium (niobium), titanium and rare earths for improved high temperature strength and resistance to carburization and oxidation up to 1950 ° F (1066 ° C). Microalloying produces fine, stable carbides which retard dislocation movement, thereby increasing elevated temperature strength and creep resistance. Intended primarily for reforming applications. |

| HP+Nb+MA (LoSil) | TMA® 6301 | 25 | 35 | Nb 1.2 Ti Rare Earths | R&D 100 Award Winner heat resistant alloy developed by Duraloy. TMA ®6301has a proprietary, microalloyed, computer designed chemistry which gives the alloy better high temperature creep properties than similar alloys. It is intended primarily for reforming applications. |

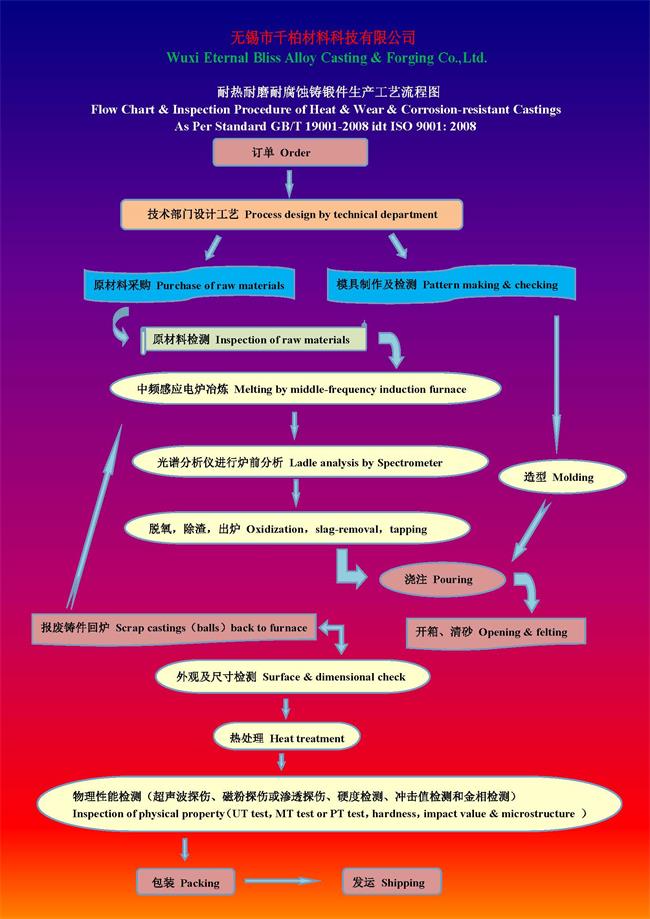

Production Process

![]()

1. 18-year Foundry Operation Experience.

2. Friendly & High Efficient Technical & Commercial Communication.

3. Professional Export Practices: Have Exported to +60 Overseas Countries.

Our Trade Show

Our booth No. 14-A29-5 in Newcast 2015,Germany

Hall 14, Stand No.A29-5.

Contact Us for further information about products & service:

Mr.John Liu

Project Manager

Tel: 0086-188 0059 6372

Fax: 0086-510-6879 2172

Email : cast@ebcastings.com; ebcastings@163.com

Skype ID:julia.zhu26

QQ: 217 039 6403

What's app: 0086-130 930 23772

Eternal Bliss Alloy Casting & Forging Co.,LTD.

Add.: J-Sci-Tech Park, Binhu District,Wuxi,214122, Jiangsu,China

Our Inspection Video: