Hunan Dinghan New Material Technology Co., LTD |

|

Verified Suppliers

|

|

Nickle Alloy disc, a thin, projecting metal stripattached to asemiconductor to dissipateheat. It is widely used incatering and kitchenware,elevators,chemical equipment,machinery manufacturing,architectural decoration, metaproducts, automobiles, pressurevessels and other felds

Monel 400 (UNS NO4400/W.Nr. 2.4360) is a nickel-copper alloy (about 67% Ni- 23% Cu) that is resistant to sea water and steam at high temperatures aswel as to salt and caustic solutions. Aloy 400 is a solid solution alloy that can only be hardened by cold working. This nickel alloyexhibits characteristics like good corrosion resistance, good weldability and high strength. A low corrosion rate in rapidly flowingbrackish or seawater combined with excellent resistance to stress-corrosion cracking in most freshwaters, and its resistance to avariety of corrosive conditions led to its wide use in marine applications and other non-oxidizing chloride solutions.

Corrosion Data:

Monel alloy 400 offers great stress corrosion cracking in most freshwaters. Due to Copper it offers resistance to marine application ( salt water ), steam water even at high temperature. Good Resistance to hydrochloric acid , sulphuric acids while de-aerated. Resistance to Neutral & Alkaline salts. Resistance to chloride stress corrosion cracking.

Chemical Composition:

| Element | C | Si | Mn | S | Cu | Fe | Ni+Co | Co |

| Minimum(%) | - | - | - | - | 28 | - | 63 | - |

| Max(%) | 0.3 | 0.5 | 2 | 0.024 | 34 | 2.5 | 70 | 2 |

Nature:

| State | Approximate tensile strength (N/mm²) | Approximate Operating Temperature(°C) |

| Annealing | 400-600 | -200 to +230 |

| Elastic tempering | 800-1100 | -200 to +230 |

Our QC Activities and Test Methods:

| Chemical Analysis | ASTM E1473ensile | Test | ASTM E8 |

| Hardness Test | ASTM E 10,E 18 | PMl Examination | DINGSCO SOP |

| Ultrasonic NDT | BS EN 10228 | Liquid Penetrant NDT | ASTM E 165 |

| Dimensional and inspection | DINGSCO SOP | Roughness Test | DINGSCO SOP |

| Impact Test | ASTM E 23 | Low Temperature lmpact Test | ASTM E 23 |

| Creep and Stress Rupture Test | ASTM E 139 | Hydrogen Induced Cracking Test | NACE TM-0284 * |

| Inter Granular Corrosion Test | ASTM A 262 * | Sulfide Stress Corrosion Cracking Test | NACE TM-0177 * |

| Pitting and Crevice Corrosion Test | ASTM G 48 * | Macro Etching Test | ASTM E 340* |

| Grain Size Test | ASTM E 112 * |

* Done by state own third party laboratory

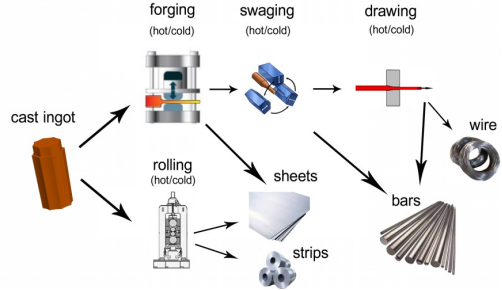

Processing Flow Chart: