| Hidden Type Roof Sheet Roll Forming Machine with Manual Decoiler |

| Main motor power | 4kw |

| Drive | 1'' single chain |

| Type: | Wall board |

| Main shaft dia | ¢70mm |

| material | 45# forge steel and quenched |

| Roller material | 45# high grade forge steel ,chrome coated 0.05mm |

| Roll station | 18 groups |

| Raw material | 0.3-0.8mm |

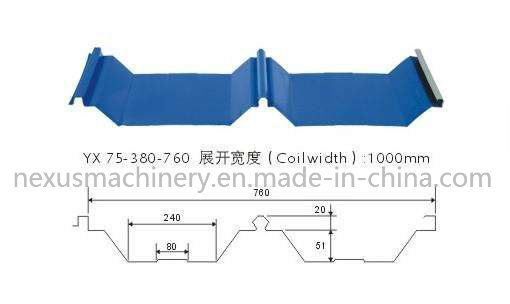

| Coil width | 1250mm |

| Working speed | 10m--15m/min(Exclude cutting time) |

| Length Tolerance | ±1.5mm |

| Weight of machine | About 5 ton |

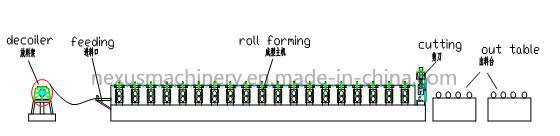

| Size of machine | About 7500×1800×1500mm L x W x H |

| Color of machine | Yellow and Blue |

| Coder | Omron, made in Japan |

| Control | PLC Panasonic, made in Japan. 380V 50HZ,3phase (Also depend on client) |

| Computer operating panel | touching screen |

| Other electrical element | Schneider |

| Cutting | Hydraulic cutting. Auto cutting when reach the set length |

| Hydraulic power | 3KW |

| Blade material | Cr12mov,quenched 58°-62° |

| Working pressure | 16mpa |

| Cutting tolerance | +/- 1.0mm |