Guangdong Kenwei Intellectualized Machinery Co., Ltd. |

|

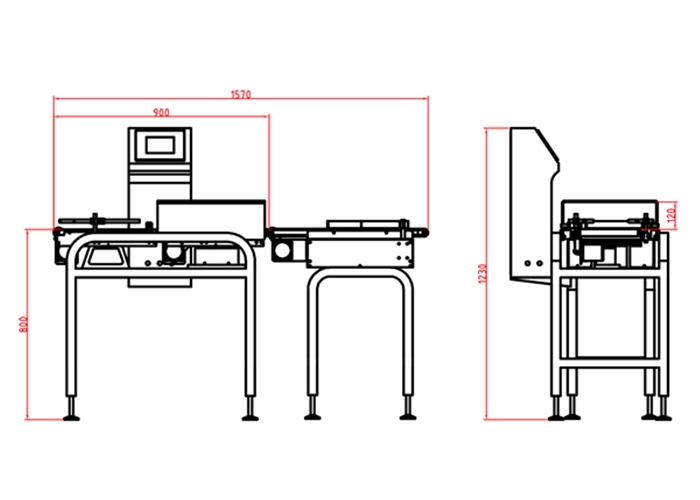

Check Weigher For Sorting 1000g Products With Pneumatic Pusher Reject

Based on the actual situation of customers, research the production characteristics, make comprehensive assessment planning programs with high adaptability. The check weigher is used to detect whether the weight of a single product is consistent with the set target, and the sorting device automatically rejects the substandard name of the substandard intelligent design. Check weigher has a variety of models for customers to choose from, and there are many types of rejection methods, including arm rejection, pneumatic pusher rejection, air blowing rejection, and drop type rejection. This is pneumatic pusher rejection, where the product passes the weight check, unqualified products, the pneumatic pusher quickly rejects it, fast and accurate.

Features

Technical specification

| Model | JW-C200 | JW-C1000 | JW-C2000 | JW-C3000 | JW-C6000 |

| Identify Code | C200-2-1 | C1000-1-1 | C2000-1-1 | C3000-1-1 | C6000-1-1 |

| Weighing Range | 5-200g | 10-1000g | 10-2000g | 10-3000g | 10-6000g |

| Accuracy | XIII(1) | XIII(1) | XIII(1) | XIII(1) | XIII(1) |

| Max.Belt Speed | 55m/min | 52m/min | 52m/min | 40m/min | 40m/min |

| Max.Speed | 100PCS | 80PCS | 80PCS | 50PCS | 40PCS |

| Belt Size(mm) | 350(L)x150(W) | 450(L)x220(W) | 450(L)x300(W) | 650(L)x400(W) | 650(L)x440(W) |

| Control Panel | 7” Touch Screen | ||||

| Reject Method | Air blowing | Air blowing/Air-reject/Pneumatic pusher/Slide type | Pneumatic pusher/Slide type | ||

| Power Requirement | 220V/400W/50/60Hz/2A | 220V/400W/50/60Hz/2A | 220V/400W/50/60Hz/2A | 220V/600W/50/60Hz/3A | 220V/600W/50/60Hz/3A |

| Packing Dimension(mm) | 1250(L)x570(W)x1150(H) | 980(L)x800(W)x1290(H) | 980(L)x860(W)x1290(H) | 1600(L)x950(W)x1490(H) | 1600(L)x950(W)x1490(H) |

| Gross Weight | 100Kg | 180Kg | 190Kg | 260Kg | 260Kg |

Application

It is used to check whether the single bag weight is conformed to the preset weight or not and auto remove the unqualified products by the rejection device.

Kenwei machinery advantages

1.2 years warranty: help customer reduce service cost, less worry, less money;

2.Brand: Industry-leading enterprises, the international production scale, one of the largest manufacturing bases of producing professional combination weigher (linear weigher/check weigher/metal detector, etc.) in the world with wide influence. We are a national high-tech enterprise.

3.Ten years experience: Ten years of customized experience of weighing production system, provide high-precision, high-efficiency production line for customers, greatly enhance the customer's profitability.

4. Customized group: We have a technical team with a rapid response for special projects to meet the different requirements for customers.

5. Meet individual needs: Based on the actual situation of customers, research the production characteristics, make comprehensive assessment planning programs with high adaptability.

6.Rigorous design: Rigorous weighing system design and development process to promote the overall mold, internal, and external process guidelines to enhance the accuracy and stability of the production line.

7.Serialization products: We have a series of products to adapt to a variety of materials, and to solve the weighing materials adaptability problem.

8.Stable precision mode: We use a "stable time development model" in program design and development. This development mode is the core element to ensure weigher be in long-time stable operation and make material saving maximize.

9.Test: Simulate customer production materials, equipment operation, and other work environments, as much as possible to restore the customer's production status, access to get the real test data.

10.Good service:Kenwei service department is including test group, planning group, door-to-door service groups, etc, mainly to provide commission for specific materials and make commission regularity indicators so that to find out the suitable material for the machine;