Guangdong Kenwei Intellectualized Machinery Co., Ltd. |

|

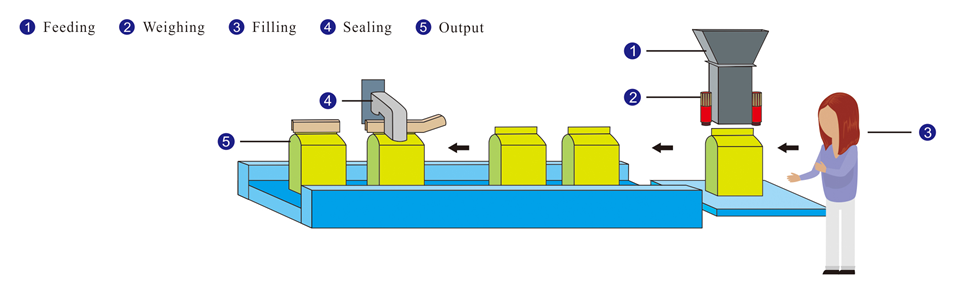

Two outlet semi auto weighing and packaging system (with vacuum feeding machine and linear weigher)

System including: vacuum feeder,4 head linear weigher, working platform,sealer.

Mechanical character

| 1.Save space and input cost. |

| 2.Suitable for weighing powder, High weighing precision, and efficiency. |

| 3.Packaging speed 30-40p/min (need two-person to collecting the product, the multihead weigher is in a normal load working state). |

1. Fully-automatically completes all the process from feeding,

weighing and finished products outputting;

2. Wide scope of application, Suitable for various materials.

3. Save space and input cost, High weighing precision, and efficiency.

4. suitable for weighing powder and roll or regular shape granule.

5. cheapness, high price ratio, Suitable for kinds of bag type

which cann’t made by packaging machine.

It is suitable for weighing powder and roll or regular shape granule, such as sugar, salt, seed, rice, sesame, glutamate, milk powder, coffee and season powder, etc.

Accuracy

Taking into consideration that the mode of the main vibrator and linear vibrator and vibration absorption ability of the framework that has the effect to weigher accuracy, Kenwei independent research and develop both standard and high amplitude vibrators to meet the needs of different materials. Also control the vibrating time and amplitude separately by control systems to automatically adjust the linear vibrator amplitude, which makes the material flow optimization; About the middle base of machine case, we always use 2.5mm-3.0mm stainless steel sheet and strengthen the internal structure by providing reinforcement to ensure the machine's rigidity. Some models take the machine case and middle base integrated, through a combination of AD converter module and anti-jamming technology, which effectively reduce the vibrating interference and ensure the accuracy of the machine running.

Quality:

A. The quality department is equipped with an environmental simulation test, frequency test, and waterproof test, which mainly used to simulate the high and low-temperature environment, research, and coping machine working conditions under different voltage and frequency, do well for the 50/60Hz frequency and vibration / rotary top cone inspection.

B. Our quality department is Including material checking, inspection, QE, checking before and after the aging test and finished product inspection, etc. total 16 inspection positions and steps.

C. We pay high attention to material inspection and finished product inspection of these two organizational structures.

D.Key components such as circuit boards, screens must be in 72 hours nonstop aging test at 50 ℃ environments. Each machine before delivering must be in 7 days nonstop aging test.