Henan Ascend Machinery Equipment Co., Ltd. |

|

Verified Suppliers

|

|

Customer Requirements:

Raw material: Sulfer Copper ore

Input Material size: 350mm

Final Products Requirement: 23% copper ore concentrate.

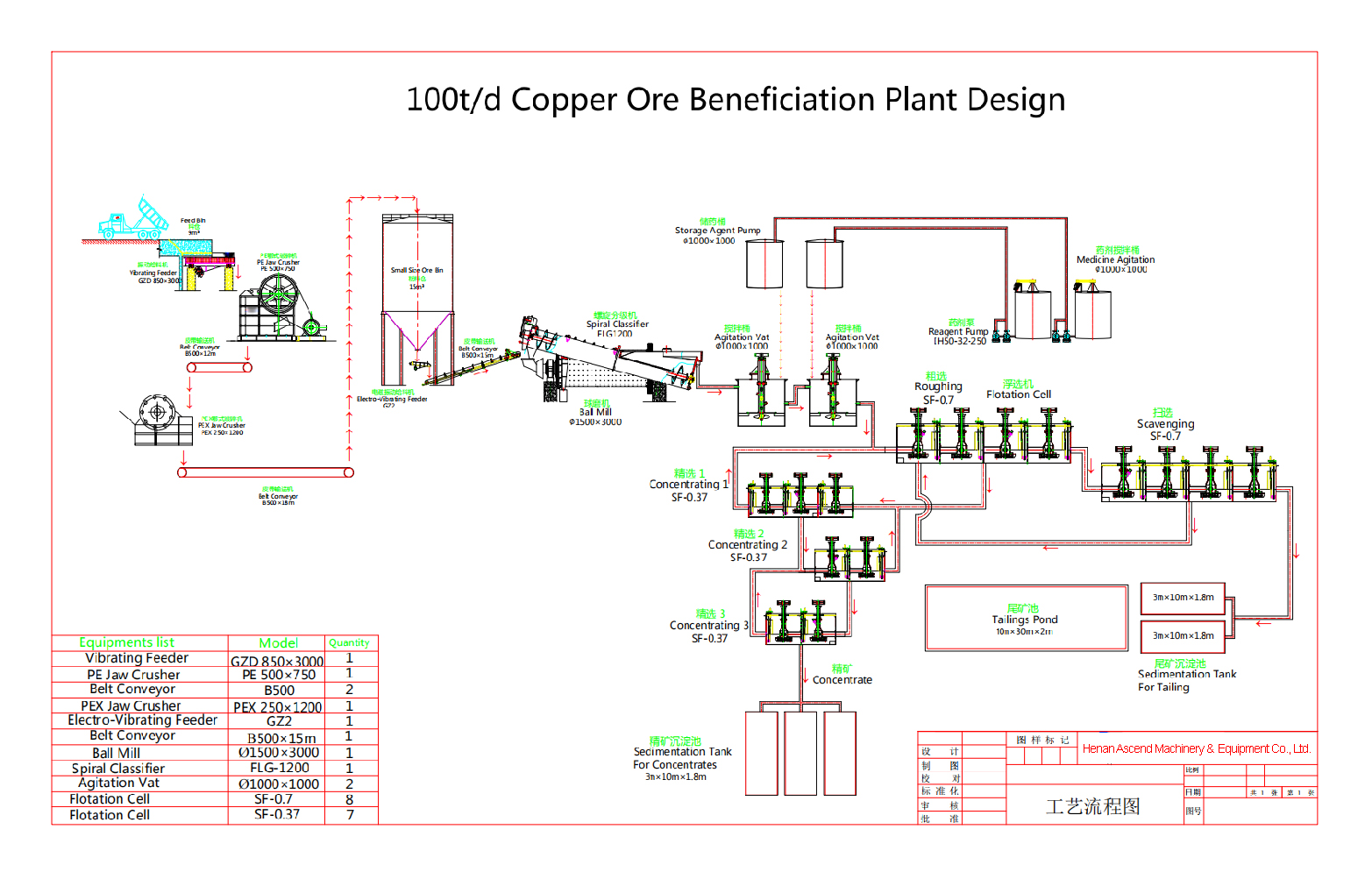

Production Process: The raw ore is fed into the coarse crusher by the vibration

feeding machine, and then enters the fine crusher. After the fine

crushing, the product enters the sieve and sieves, and the sieved

material is returned to the fine crusher and then broken. The

undersize material is a qualified product that enters the powder

ore bin. The powder mine is set up under the mining machine, and

the powder mine is fed into the ball mill through the belt

conveyor. The ball mill discharges into the spiral classifier, and

the spiral classifier returns the sand into the ball mill. The

spiral classifier overflows into a rough selection, three

selections, and a flotation operation. The flotation concentrate

enters the sedimentation tank. The flotation tailings are thrown to

the tailings pond.

The main line of this production line is:

1 set of PE500×750 jaw crusher;

2 sets of PEX250×1200 jaw crusher;

1 set of φ1500x3000 ball mill;

1 set of FLG-1200 Spiral classifer

8 set of SF0.7 Flotation cell machine

Auxiliary equipment: Vibrating feeder, belt conveyors form a

production line.

PE Jaw crusher

Flotation machine

Flotation machine Specifications

| Model | volume (m3) | processing power (m3/min) | impeller diameter (mm) | impeller speed (r/min) | main motor power (kW) | Scraper motor power (kW) | tank weight (T/slot) |

| SF0.37 | 0.37 | 0.2-0.4 | 300 | 442 | 1.5 | 1.1 | 0.45 |

| SF0.7 | 0.7 | 0.3-1 | 350 | 400 | 3 | 1.1 | 0.9 |

| SF1.2 | 1.2 | 0.6-1.2 | 450 | 312 | 5.5 | 1.1 | 1.4 |

| SF2.8 | 2.8 | 1.5-3.5 | 550 | 268 | 11 | 1.1 | 2.2 |

| SF4 | 4 | 2-4 | 650 | 235 | 15 | 1.5 | 2.6 |

| SF8 | 8 | 4-8 | 760 | 191 | 30 | 1.5 | 4.3 |

| SF16 | 16 | 5-16 | 850 | 190 | 45 | 1.5 | 7.4 |

| SF20 | 20 | 5-20 | 730 | 186 | 30*2 | 1.5 | 9.8 |