Changzhou Vic-Tech Motor Technology Co., Ltd. |

|

Verified Suppliers

|

|

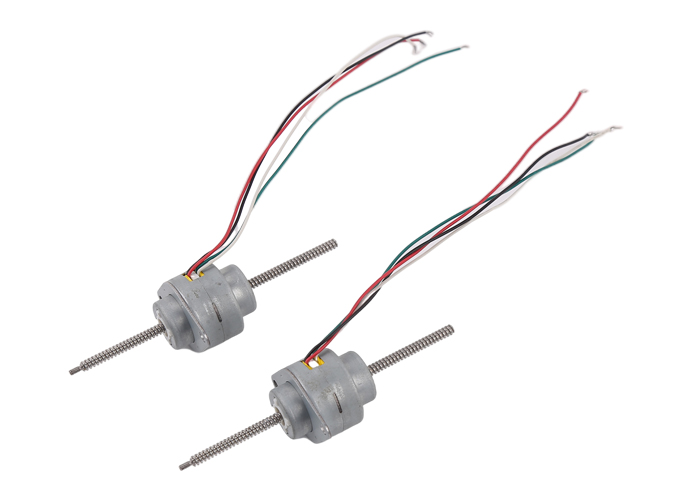

VSM25B-24S 15° step angle PM run through shaft trapezoidal screw linear stepper motor

Description:

VSM25B-24S is a 25mm diameter linear stepper motor with run-through shaft.

We have three different type of shafts: run-through shaft, captive shaft and external drive.

The step angle is 15°/step, and we also have 7.5°gear ratio for choice.

The step length is 0.0254mm, and it means the lead screw travels 0.0254mm when the motor take one single step.

Step angle is determined by lead screw starts.

With more starts, lead screw lead is bigger, and lead screw travels faster, and lead screw thrust is smaller.

We have single start, 2 starts and 4 starts, and lead screw pitch is the same: 0.6096mm.

For this motor, lead screw lead is 0.6096mm, and it is single start.

Please confirm lead screw type and lead before you order samples.

Parameters:

| Model No. | VSM25B-24S |

| Shaft type | Run through shaft |

| Step angle | 15° |

| Voltage | 12V DC |

| Coil resistance | 70Ω |

| Lead screw | 0.6096mm (single start) |

| Step length | 0.0254mm/step |

| Stroke | 52mm (adjustable) |

| Net weight | About 50 grams |

Design drawing:

Product display:

About linear stepper motor:

There different design:

Captive shaft(fixed shaft): the lead screw is not allowed to spin, it can only go up and down, do linear motor movement.

Run-throught shaft (through going shaft): the lead screw can move up and down when spinning. When lead screw is fixed, not allow to rotate, lead screw can move up an down, and work properly.

External drive(with nut): The lead screw is fixed, can’t move up and down, it can only spin, and there is a nut on the lead screw to move up and down.

About lead screw and step length:

We have two types of step angle: 15°and 7.5°. Motors with 15° step angle takes 24 steps for one turn, and motors with 7.5° step angle take 48 steps for a turn.

We have three types of lead screw lead, with single start/doule starts and 4 starts.

Pitch is the same: 0.6096mm

Lead screw lead=starts*pitch

For examples, for 2 starts lead screw, lead is 2*0.6096=1.2192mm

Motor’s step length, is the distance lead screw/nut travels when the motor takes one step.

Motor’s step length=lead screw lead/steps for each turn

For examples,for 2 starts lead screw, step angle is 7.5°,

Step length=lead/24=1.2192/24=0.0508mm/step

About thrust:

Thrust is related to driver’s frequency and lead screw lead, stepper angle and motor size.

The bigger motor’s size, thrust is bigger.

The lower frequency it get, motor rotate slower, and thrust is bigger.

The lower lead screw lead is, thrust is bigger.

7.5 degrees step angle will have higher thrust compared to 15 degrees.

Application of stepper motors:

Stepper motors are used for precise control, widely used on medical equipment, 3D printer, industrial precise control, automation equipment, etc.

Stepper motors can be used in any mechanisms requirement precise conrtol and rotational/linear movement.

Advantage of stepper motors:

Stepper motor can reach precise control even without close-loop encoders / without feed back system, also they do not have electrical brushed. Thus there is no electromagnetic interference and electrical sparks issues. In some cases, they can replace DC brushed motors/ brushless motors.

Stepper motors are easy to control with drivers, and this feature establish its important position in the field of precise control.

1. Precise control achievable, programmable

2. Without electromagnetic interference & electrical sparks

3. Small size

4. Reasonable price

5. Low noise

6. Long service life

Packaging and Shipping information:

Samples are packed with foam sponge inside paper box.

For mass production, products are packed in paper carton.

For sea shipping (Mass production), cartons are packed on pallet.

Shipping time:

By express(DHL/ UPS/ Fedex/ TNT): 5~12 days

By 4PX express: 10~20 days

Sea shipping: 40~60 days (depends on different countries)