Suzhou Vanforge Metals Co., Ltd. |

|

Description

700HBW steel for extreme abrasion resistance.

700HBW steel is the world’s hardest wear plate with a nominal hardness of 60 HRC (Rockwell) and typical hardness of 650-700 HBW.

700HBW steel is an abrasion resistant steel with a nominal hardness of 60 HRC, intended for applications with extreme high demands on abrasion resistance. Typical applications is liner plates, etc.

Dimension Range

700HBW steel is supplied in plate thickness of 8 – 19 mm, up to 2000 mm in width and up to 14630 mm in length, preferred widths are 2000 x 4000 mm, other width on request. More detailed information on dimensions is provided in the dimension program.

Mechanical Properties

Thickness (mm) | Typical Hardness (HRC) |

| 8.0- 19.0 | 57- 63 |

Chemical Composition, %, max

| C | Si | Mn | P | S | Cr | Ni | Mo | B |

| 0.47 | 0.50 | 1.40 | 0.015 | 0.010 | 1.20 | 2.50 | 0.80 | 0.005 |

The steel is grain refined.

Thickness

Tolerances meet the requirements of EN 10029 Class A

Length and Width

Tolerances conforms to EN 10029

Shape

Tolerance according to EN 10029.

Flatness

Tolerances according to EN 10029.

Surface Properties

EN 10163-2 Class A Subclass 1

Delivery Conditions

The delivery condition is Q (Quenched). The plates are delivered with sheared or thermally cut edges. Untrimmed edges after agreement.

Fabrication and Other Recommendations

Welding, bending and machining.

700HBW steel is not intended for further heat treatment. It has obtained its mechanical properties by quenching and when necessary by means of subsequent tempering. The properties of the delivery condition cannot be retained after exposure to temperatures in excess of 150 ºC.

Appropriate health and safety precautions must be taken when welding, cutting, grinding or otherwise working on the product. Grinding, especially of primer coated plates, may produce dust with high particle concentration.

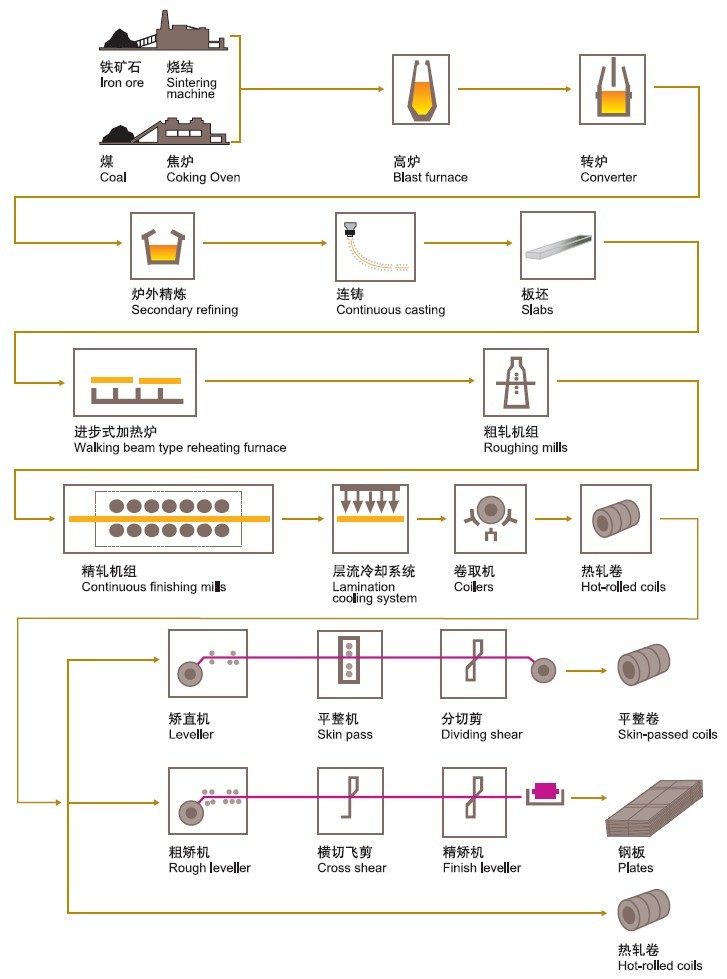

Production process