DLY Metal Roofing Machine |

|

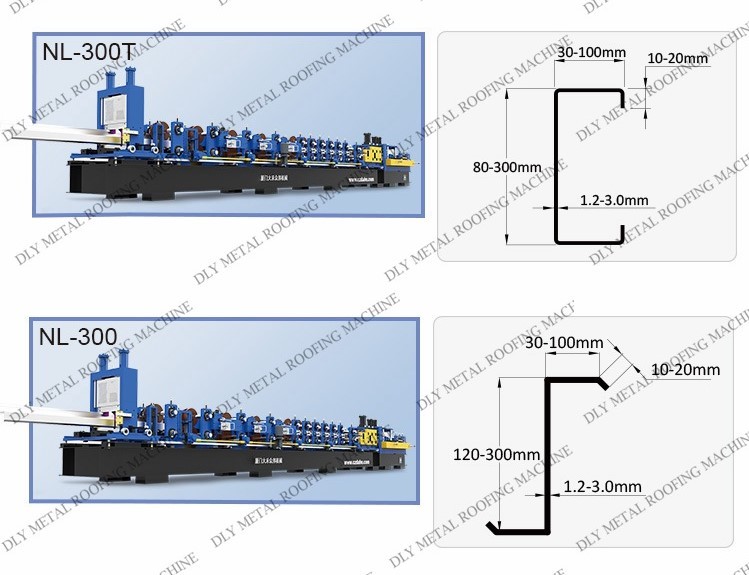

15kw 380V Automatic Purlin Roll Forming Machine With Hydraulic Cutting

1. Description of C U Z Purlin Roll Forming Machine

Our purlin machine driven by gearboxes, consists of decoiler, feeding and levelling device, punching system, pre-shear, roll forming system, hydraulic post cutting, run out table, hydraulic station and PLC(controlling system). Its special feature: Assemble with liner guide way to make machine change web size easily and smoothly, Produce standard products with yield strength up to 550Mpa,Long production line,no open mouth on final products, C/Z interchange only with 3 steps and within 5-15mins;Changing size fully automatically. Time saving and labor saving, which is highly improved production efficiency and suitable for current production. This machine is easy to operate and run stable with good precision. Large range web size is 120-450mm and thickness up to 4.5mm, which used widely and would be the most popular model in the near future.

2. Specifications of C U Z Purlin Roll Forming Machine

| Machinable Material : | A) Galvanized Coil | Thickness(MM): 1.5-3 |

| B) PPGI | ||

| C) Carbon steel Coil | ||

| Yield strength : | 250 - 550 Mpa | |

| Tensil stress : | G350 Mpa-G550 Mpa | |

| Decoiler : | Manual decoiler | * Hydraulic decoiler (Optional) |

| Punching system : | Hydraulic punching station | * Punching press (Optional) |

| Forming station : | 18-20 stations | |

| Main machine motor brand : | Shanghai Dedong (Sino-Germany Brand) | * Siemens (Optional) |

| Driving system : | Chain drive | * Gearbox drive (Optional) |

| Machine structure: | Wall panel station | * Forged Iron station (Optional) |

| Forming speed : | 10-20 (M/MIN) | * Or according to your profile drawings |

| Rollers’ material : | Steel #45 | * GCr 15(Optional) |

| Cutting system : | Pre-cutting | * Post- universal cutting (Optional) |

| Frequency changer brand : | Yaskawa | * Siemens (Optional) |

| PLC brand : | Panasonic | * Siemens (Optional) |

| Power supply : | 380V 50Hz | * Or according to your requirment |

| Machine color : | Industrial blue | * Or according to your requirment |

4. Advantages of C U Z Purlin Roll Forming Machine

5. Detail photos of C U Z Purlin Roll Forming Machine