Jiangyin Dingbo Technology CO., Ltd. |

|

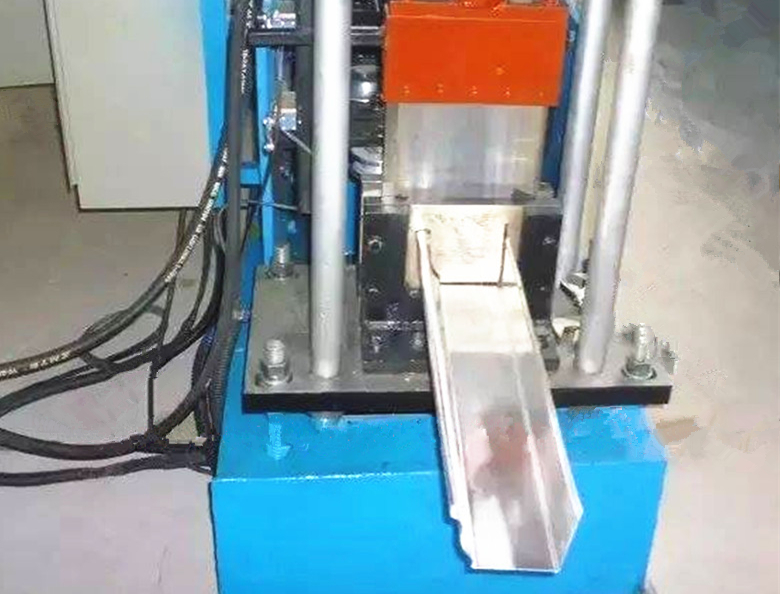

Gutter Roll Forming Machine

Product Descriptions

The gutter, also known as the "rain trap", is a narrow passage or

trough that forms part of a roof system that collects and transfers

rainwater from the edge of the roof.

The main purpose of the gutter is to protect the foundation of the

building by taking water out of the base. Drains also help reduce

erosion, prevent leakage in basements and crawl spaces, protect

painted or stained surfaces by reducing exposure to water, and

provide a means of collecting rainwater for later use.

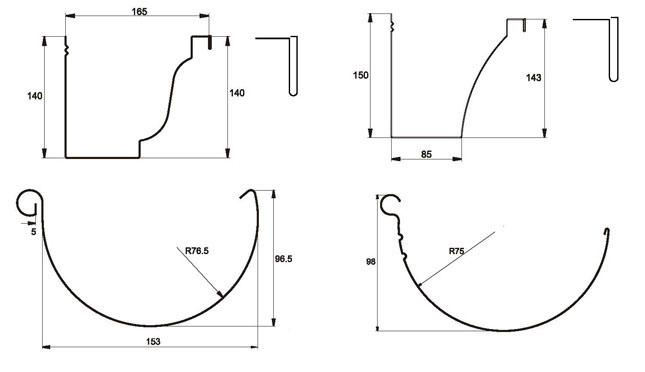

Version to design

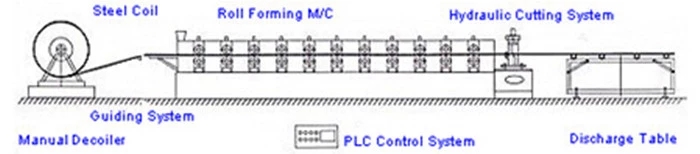

Working Flow

Decoiler --Guiding device --Forming system -- Cutting device-- Output table

Product Parameters

1. Suitable to process: Color steel plate

2. Width of the plate: 330mm

3. Rollers: 17rows

4. Dimensions: 9.1*1.35*1.51m

5. Power: 5.5+3kw

6. Rolling material: 45# steel(plated chrome on surface)

7. Thickness of the plate:0.3-0.6mm

8. Voltage: 380V 50Hz 3phases

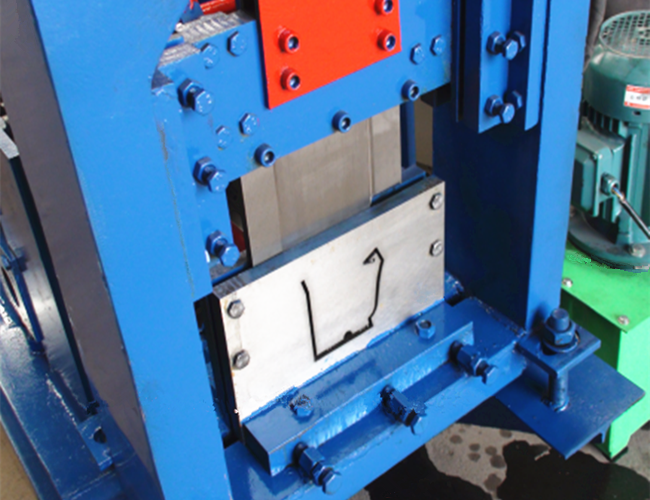

9. Material of the cutting plate: Cr12

10. Hydraulic: 40#

11. Processing precision: Within 1.00mm

12. Control system: PLC control

Main Components

| No | Name | Quantity | |

| 1 | Decoiler | 1set | |

| 2 | Main machine | Feeding device | 1set |

| Roll forming system | 1set | ||

| Post cutting device | 1set | ||

| Hydraulic system | 1set | ||

| 3 | Electric control system | 1set | |

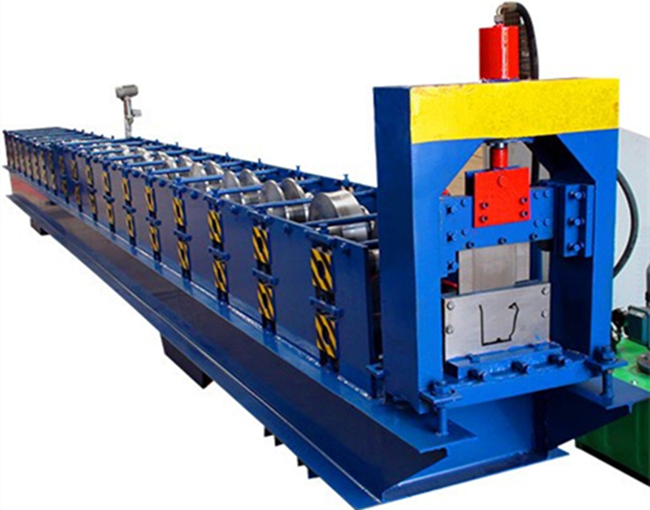

Machine pic

Application

Our service

Designing:

After order confirmation, we start to design the machine, such as the basement, structure, rollers, shafts, power, cutting device, programs and so on.

Making:

The main parts, like rollers and shafts are produced by ourselves. We have several high-precision CNC lathe and other kinds of new machine tools, so that the quality and precision can be controlled.

Assembling:

The machines are assembled by technicians with years of experience, which can help workers improve the production efficiency and machine’s quality.

Testing:

Raw material of different specifications are prepared for testing. And during test, long enough material is used. Because if the material is not long enough, some defects can not be exposed.

Delivery:

Machine will be fixed inside container by steel wire, in order to make sure it won’t move during transportation and avoid any kinds of damage of machine and container.

Main features

1. We can make and design all kinds of roll forming machine according to customer's requests.

2. This is a very perfect and durable equipment. We have more than

20 years experiences.

3. This kind of machine has the best quality and the best price. It

has accurate measurement and easy operating.

4. We can design and manufacture the special type machine according

to the customers' requirement and we could provide technical

guiding, production, installation, debugging and maintenance

service to all customers.

5. Our product has been exported to many regions and won high

reputation because of the high quality and reasonable price.