Quanzhou Yuanyuan Cloud Technology Co., Ltd. |

|

Verified Suppliers

|

|

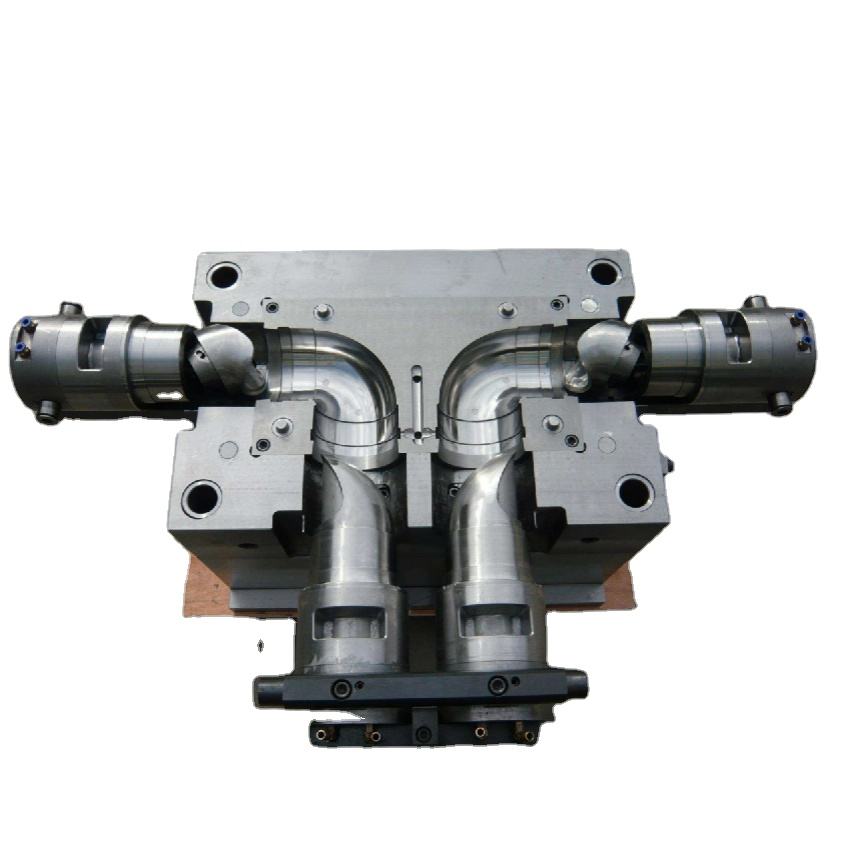

China Deformable pipe handle custom mold maker Toy mould shrinkage pipe injection plastic mold manufacturer

The realm of industrial manufacturing is marked by the continual quest for efficiency, precision, and reliability, and this is where the concept of mold development comes to the forefront. In the heart of China's industrial milieu, a product that has set a benchmark for quality and adaptability is the Plastic Injection Mould. This mold development product is the epitome of innovation and performance, designed to cater to a myriad of manufacturing needs while offering unparalleled customization options. The product summary herein delves into the details of this exceptional tool, highlighting how it stands as a beacon of industrial prowess.

At the core of this product is the customization capability that it offers. Recognizing that every manufacturing process is unique, the Plastic Injection Mould is created with an emphasis on meeting the specific requirements of each client. Whether it’s a variation in size, shape, or complexity, this mold development solution from China is tailored to the exact specifications provided. The result is a highly specialized tool that integrates seamlessly into the manufacturing process, thereby enhancing productivity and reducing downtime.

Application of this product spans the vast expanse of industrial manufacturing. Its versatility is demonstrated in its ability to produce a wide array of plastic components, ranging from simple household items to intricate parts for automotive or aerospace industries. The Plastic Injection Mould is not just a tool; it is a gateway to realizing designs that once seemed impossible or impractical to manufacture. The advanced technology employed in the production of these molds ensures that they are suitable for high-volume manufacturing, maintaining consistency and quality across thousands, if not millions, of parts.

When it comes to speed, this product stands out as a fast solution in the world of mold development. Time is a critical factor in manufacturing, and the Plastic Injection Mould is designed to minimize cycle times, thereby accelerating the production process. This rapidity does not come at the expense of quality. Instead, it is a harmonious balance between efficiency and excellence, ensuring that products hit the market without delay and without defects. Fast turnaround times are especially crucial in industries where time-to-market can be the difference between leading the pack and lagging behind.

Design flexibility is another significant attribute of this mold development product. The high level of design freedom allows for the creation of complex geometries and intricate features that would be difficult or impossible to achieve with other manufacturing methods. This design flexibility is made possible by the sophisticated mold design software and state-of-the-art manufacturing techniques prevalent in China’s industrial sectors. As a result, designers and engineers are not constrained by the limitations of the mold-making process; instead, they can push the boundaries of creativity and functionality.

Material selection is pivotal in mold development, and the choice of plastic as the primary material for the Plastic Injection Mould is a testament to its versatility and durability. Plastic offers numerous advantages, including resistance to corrosion, light weight, and the ability to be produced in a vast spectrum of colors and textures. The molds themselves are crafted from robust materials capable of withstanding the high pressures and temperatures inherent in the injection molding process, ensuring a long service life and consistent performance.

In conclusion, the Plastic Injection Mould from China is a product that epitomizes the fusion of speed, flexibility, and customization in mold development. Its application across various sectors of industrial manufacturing underscores its adaptability and effectiveness. With its high design flexibility and fast production capabilities, it stands as an indispensable tool for businesses looking to maintain a competitive edge in a fast-paced market. Embracing this advanced mold development solution means embracing innovation, efficiency, and superior quality in plastic part production.

| Parameter | Specification |

|---|---|

| Size | Customizable |

| Quality Control | Strict |

| Durability | High |

| Compatibility | Wide Range Of Materials |

| Speed | Fast |

| Material | Plastic |

| Cost | Cost-effective |

| Precision | High |

| Design Flexibility | High |

| Efficiency | High |

The Model Number 001 Plastic Injection Mould, originating from China, represents a pinnacle of precision engineering certified by ISO standards, ensuring the highest quality in industrial manufacturing applications. This mold is a selected product among our offerings, renowned for its high precision and customizable sizing to meet a variety of needs. The versatility of this mold allows for compatibility with a wide range of materials, making it an indispensable tool for companies aiming to produce plastic components with exacting specifications.

Our minimum order quantity for this premium product is set at 100 pieces, with each piece priced competitively at 1 unit. The packaging details are meticulously handled with neutral packing to ensure the safe transportation and delivery of the product. With a standard delivery time of 30 days, we make sure that our clients receive their orders within a reasonable timeframe, allowing for seamless integration into their production schedules. Payment is streamlined through TT (Telegraphic Transfer), and with a robust supply ability of over 10,000 pieces per 7 days, we are well-equipped to handle orders of any size.

The application occasions and scenarios for the Model Number 001 Plastic Injection Mould are extensive and varied, encompassing a broad spectrum of industrial manufacturing processes. Whether our clients are engaged in the automotive industry, consumer electronics, home appliances, or any other sector that requires the mass production of plastic parts, this mould is designed to deliver exceptional performance. The high precision of this selected product ensures that each component produced meets strict dimensional tolerances, resulting in consistent quality and reducing the need for post-production adjustments.

Furthermore, the customizable size feature of our Plastic Injection Mould allows for a tailored approach to mold design, accommodating the unique requirements of each specific product. This flexibility, combined with the mould's compatibility with a wide range of materials, opens up countless possibilities for product development and innovation. From prototyping to full-scale production, the Model Number 001 is the mold of choice for businesses seeking to maintain a competitive edge in the marketplace through the use of selected products that guarantee efficiency, reliability, and superior product outcomes.

Model Number: 001

Place of Origin: China

Certification: ISO

Minimum Order Quantity: 100

Price: 1

Packaging Details: Neutral Packing

Delivery Time: 30 days

Payment Terms: TT

Supply Ability: 10,000+ pcs per week

Application: Industrial Manufacturing

Compatibility: Wide Range Of Materials

Size: Customizable

Cost: Cost-effective

Durability: High

Discover the precision of our customized Mould development services tailored for industrial manufacturing. Our Selected Products are designed to meet the unique requirements of your projects, ensuring compatibility with a wide range of materials. With the model number 001 , you can trust the quality and durability of our moulds, all certified under ISO standards and available at cost-effective prices. Benefit from our robust supply ability of over 10,000+ pcs per week and experience seamless integration into your manufacturing process with our customizable size options and high durability standards. Choose our Mould development services for your Selected Products and enhance the efficiency and output of your industrial operations.

Our Mold Development Product comes with comprehensive technical support and services to ensure that you get the most out of your investment. Our team is dedicated to providing you with expert guidance and assistance throughout the entire lifecycle of the product.

Technical Support:

- Troubleshooting Assistance: Our skilled technicians are available to help diagnose and resolve any issues you may encounter with your mold development product.

- Online Resources: Access a wealth of online resources, including FAQs, user manuals, and troubleshooting guides to help you quickly find answers to common questions.

- Software Updates: Keep your mold development product up-to-date with the latest software enhancements and bug fixes to maintain optimal performance.

Services:

- Training: We offer comprehensive training programs to help your team become proficient in the use of our mold development product, ensuring you can make the most out of its features and capabilities.

- Maintenance Services: To prolong the life of your product, we provide maintenance services that include regular check-ups and preventive care, tailored to your specific usage patterns and needs.

- Consultation: Our experts are available to provide consultation on best practices for mold design and development, helping you to achieve the best results in your projects.

Our commitment to providing exceptional support and services is unwavering. We are here to help you achieve success with our mold development product. If you need assistance or have any questions, please reach out to our support team.

Our Mold Development Product is meticulously packaged to ensure that it reaches you in pristine condition. The packaging is designed to protect the product from any potential damage during transit. It is encased in a sturdy, protective material that is resistant to shocks and vibrations.

Before shipping, each package is carefully inspected to ensure that it meets our high-quality standards. We take every precaution to secure the product within the packaging, minimizing any movement that could lead to wear or damage.

We use reliable shipping carriers to ensure that your product is delivered promptly and safely. Tracking information will be provided so you can monitor the shipment's progress and anticipate its arrival.

Please inspect the product upon arrival and report any issues immediately to our customer service team. We are committed to your satisfaction and will work swiftly to resolve any problems with your order.

Q1: What is the model number of the mold development product?

A1: The model number of the mold development product is 001.

Q2: Where is the mold development product manufactured?

A2: The mold development product originates from China.

Q3: Does the mold development product have any certifications?

A3: Yes, the product is certified by ISO.

Q4: What is the minimum order quantity for the mold development product?

A4: The minimum order quantity for the product is 100 units.

Q5: Can you provide the pricing and packaging details for the mold development product?

A5: The price for the mold development product is set at 1 unit. It comes with neutral packing.

Q6: What is the expected delivery time for the mold development product?

A6: The delivery time for the product is approximately 30 days.

Q7: What are the payment terms for purchasing the mold development product?

A7: The payment terms are TT (Telegraphic Transfer).

Q8: What is the supply ability for the mold development product?

A8: The supply ability for the product is more than 10000 pieces every 7 days.