Quanzhou Yuanyuan Cloud Technology Co., Ltd. |

|

Verified Suppliers

|

|

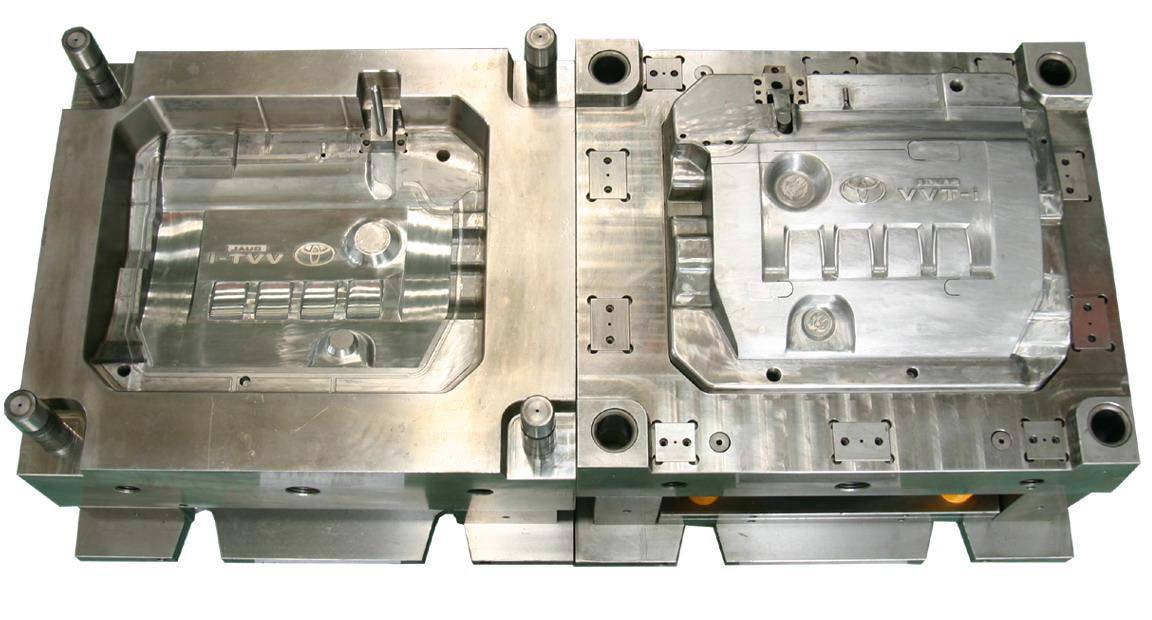

If you are involved in the manufacturing sector and are looking to streamline your production process with high precision and efficiency, then considering our mold design product is essential. Molds are crucial in shaping materials, and our product stands out in the arena of plastic injection mold parts production. With a focus on customized solutions, our mold design product caters to a wide range of applications in manufacturing, ensuring that your specific needs are met with the utmost precision.

The cornerstone of our product lies in the material used to create it. Comprising high-grade steel, the molds assure durability, longevity, and the ability to withstand the demanding environment of manufacturing processes. The choice of steel as a material not only ensures a robust mold life but also guarantees the consistent quality of the plastic injection mold parts produced, thereby maintaining your product standards.

As every manufacturing process is unique, we offer molds that are tailor-made to fit the specific requirements of your production line. Our mold size is fully customized, which means that no matter the scope or scale of your project, we can create a mold that aligns perfectly with your machinery and components. This customization eliminates the hassle and costs associated with adapting your production to standard mold sizes, providing you with a seamless and efficient manufacturing experience.

Surface finish plays a pivotal role in the quality of the final product, and it is here that our mold design product truly shines. We utilize a high standard polishing technique to ensure that the surface finish of the mold meets the highest quality benchmarks. This meticulous attention to the surface finish not only enhances the aesthetic appeal of the plastic injection mold parts but also contributes to the functionality by reducing wear and tear and facilitating the release of the molded parts.

Understanding the intricate nature of mold design, we acknowledge that mold cost is a significant factor for our clients. The cost of our molds varies depending on the complexity of the design. We work closely with you to strike a balance between cost-effectiveness and the sophisticated features of the mold. Our team of experts is adept at optimizing design to ensure that you receive the best value for your investment without compromising on the performance or quality of the final product.

Our molds are designed keeping in mind their application in manufacturing. Whether it is for mass production or for creating intricate plastic injection mold parts, our product is engineered to deliver. The precision of our molds ensures that each part produced is consistent with the last, maintaining uniformity and quality across your entire product line. This level of consistency is vital for maintaining brand integrity and customer satisfaction.

The production of plastic injection mold parts requires attention to detail and precision, and our mold design product is at the forefront of this demand. We take pride in our ability to provide molds that not only meet but exceed industry standards. Our commitment to quality, coupled with our expertise in customization, makes our molds an indispensable tool in the manufacturing of high-quality plastic injection mold parts.

In conclusion, our mold design product offers a comprehensive solution for your manufacturing needs. With a focus on material quality, customized sizing, superior surface finish, cost variability based on complexity, and application-specific design, we are dedicated to providing you with molds that are not just tools but are integral components of your manufacturing success. Choose our mold design product for an investment that will deliver precision, efficiency, and quality in the production of plastic injection mold parts.

| Attribute | Detail |

|---|---|

| Cavity Number | Single Or Multiple |

| Surface Finish | Polishing |

| Production Volume | Small To Large Scale |

| Product Type | Industrial Design |

| Lead Time | 2-4 Weeks |

| Design Process | Injection Molding |

| Mold Life | 100,000-1,000,000 Shots |

| Design Software | CAD |

| Mold Size | Customized |

| Plastic Modling Type | Injection |

The craft of mold design has been honed to perfection in the workshops of China, where precision and quality intersect to create custom mold parts that are second to none. These molds, often used in the manufacturing sector, carry the esteemed ISO certification, signifying their adherence to international standards of excellence. Entities seeking to procure these molds must note the minimum order quantity of 100, a threshold that ensures the commitment to both quality and quantity. With a competitive price point of 1, these molds present an unparalleled value proposition.

Meticulously packaged in neutral packing, the mold design products are prepared for their journey to production facilities around the globe. The delivery time stands at a strategic 30 days—a period that balances meticulous craftsmanship with the urgency of manufacturing demands. Payment for these indispensable tools is facilitated through TT (Telegraphic Transfer), a testament to the globalized nature of trade and industry. Moreover, the supply ability soars above 10,000 pieces every 7 days, a testament to the prodigious output and the relentless pace at which the workshops operate.

The application of these molds is vast, primarily found within the manufacturing sector where the transformation of materials is a daily ritual. Crafted from robust steel, these molds are engineered to withstand the rigors of production environments. The lead time is judiciously set between 2 to 4 weeks, reflecting a balance between the meticulous nature of mold making and the swift turnaround often required by clients.

Flexibility in design is showcased through the option of single or multiple cavity numbers, accommodating various production scales and complexities. Furthermore, the molds are compatible with the plastic molding type known as injection, a popular method for shaping plastic into its final form. This compatibility ensures that the custom mold parts are versatile and can be integrated into numerous plastic injection mold processes.

To sum up, whether it is a start-up venturing into the world of product manufacturing or an established conglomerate refining its production line, the mold design product from China is an essential component. It embodies a synergy of customizability, robustness, and precision, all wrapped within a framework of international certification, reasonable pricing, and dependable delivery. Such a product is not merely an instrument but a cornerstone of manufacturing excellence.

Place of Origin: China Fujian

Certification: ISO

Minimum Order Quantity: 100

Price: Contact for pricing

Packaging Details: Neutral Packing

Delivery Time: 30 days

Payment Terms: TT (Telegraphic Transfer)

Supply Ability: 10000+ pcs/7 days

Mold Cost: Varies depending on complexity of the custom mold parts

Application: Manufacturing

Product Type: Industrial Design - Custom Mold Parts

Mold Size: Customized to client specifications

Material: High-quality Steel

Welcome to the Product Technical Support and Services for our Mold Design Product. Our dedicated team of experts is committed to providing you with the highest quality support to ensure that you can fully leverage the capabilities of our software. We offer a range of services designed to help you optimize your mold design process, troubleshoot any issues you might encounter, and improve your overall productivity.

Our services include comprehensive online resources, such as tutorials, user guides, FAQs, and best practice documentation to assist you in mastering the product. For complex challenges, our skilled technical support team is ready to assist with detailed advice and problem-solving solutions. We continuously update our support resources to reflect the latest advancements and updates in our mold design product.

We also provide access to a community forum where you can interact with other users, share experiences, and find answers to common questions. The forum is monitored by our technical support specialists who contribute expert insights and guidance.

For continuous improvement, we offer advanced training sessions and webinars that cover both basic and advanced features of our mold design software. These sessions are designed to enhance your skills and knowledge, enabling you to get the most out of our product.

Please note that while we strive to ensure the accessibility of our support services, response times may vary based on the complexity of your inquiry and the volume of requests we receive. Rest assured, we prioritize all support requests to ensure timely and effective assistance.

Thank you for choosing our Mold Design Product. We are here to support your success and are committed to providing you with the best service possible. For further assistance, please refer to our contact us section for guidance on how to reach our support team directly.

Our mold design products are meticulously packaged to ensure they reach you in perfect condition. The product is first enclosed in a protective sleeve to prevent any scratches or damage during handling. It is then placed within a sturdy, custom-fitted box that provides additional cushioning and support.

Each box is sealed securely and labeled with all necessary information, including product details and handling instructions. We use only high-quality, durable packaging materials to withstand the rigors of transportation.

For shipping, we choose reliable courier services that specialize in the safe delivery of industrial products. Tracking information will be provided so you can monitor your package's journey to your location. Upon arrival, please inspect the package for any signs of damage before accepting the delivery. If you encounter any issues, contact us immediately for assistance.

Q1: Where is the Mold Design product manufactured?

A1: The Mold Design product is manufactured in China.

Q2: Does the Mold Design product come with certification?

A2: Yes, the Mold Design product comes with ISO certification, ensuring it meets international standards.

Q3: What is the minimum order quantity for the Mold Design product?

A3: The minimum order quantity for the Mold Design product is 100 units.

Q4: How is the Mold Design product priced?

A4: The price for the Mold Design product is set at 1 unit of your currency.

Q5: What are the packaging details for the Mold Design product?

A5: The Mold Design product is packaged using Neutral Packing methods to ensure safety during transportation.

Q6: What is the delivery time for the Mold Design product?

A6: The delivery time for the Mold Design product is approximately 30 days after the order is confirmed.

Q7: What are the payment terms for purchasing the Mold Design product?

A7: The payment terms for the Mold Design product are TT (Telegraphic Transfer).

Q8: What is the supply ability of the Mold Design product?

A8: The supply ability for the Mold Design product is over 10,000 pieces every 7 days.