Quanzhou Yuanyuan Cloud Technology Co., Ltd. |

|

Verified Suppliers

|

|

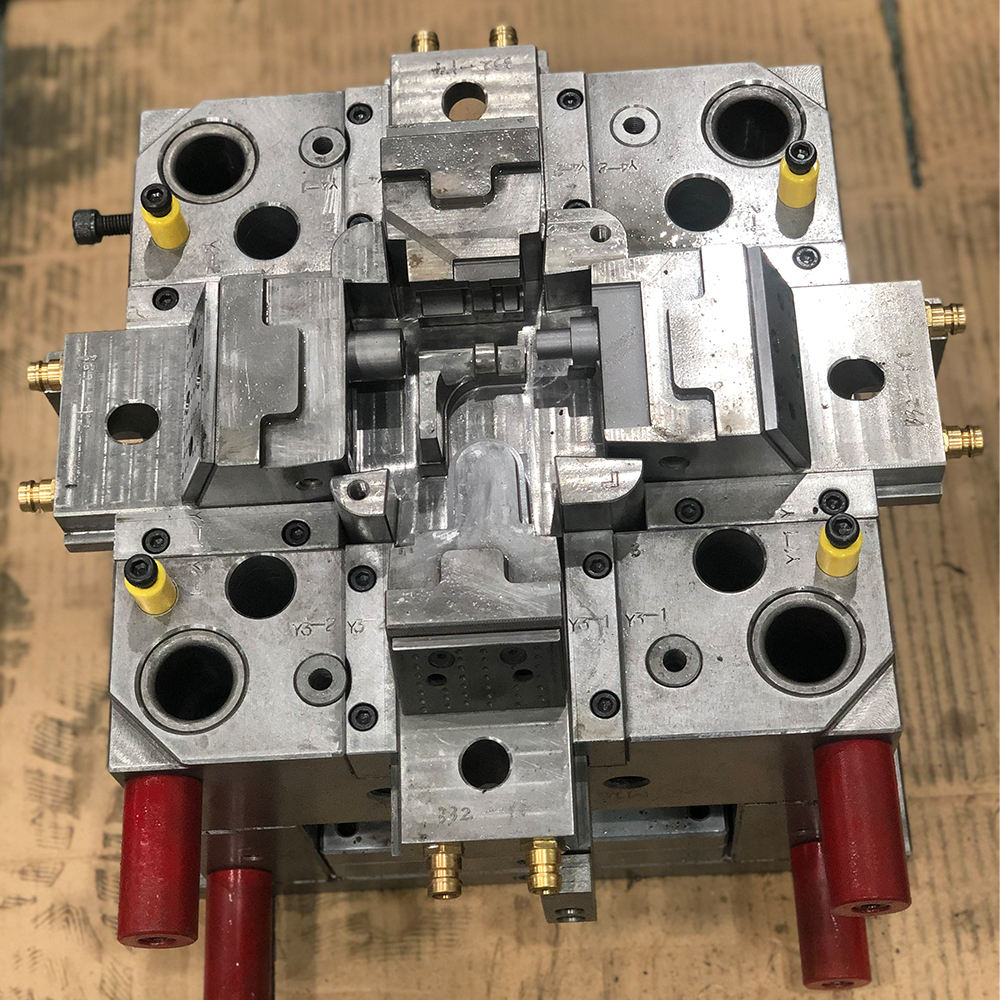

Mold design China mold maker plastic injection mold plastic Automotive parts mould metal plastic housing custom Mold

Our Mold Design product is a cutting-edge solution tailored to meet the diverse needs of the modern manufacturing industry. Utilizing advanced Computer-Aided Design (CAD) software, our team of experts crafts meticulous and precise molds that are the backbone of plastic injection molding. This essential tool is the starting point for creating high-quality, precision-engineered plastic injection mold parts that are crucial in various applications ranging from automotive components to medical devices.

Understanding that every client has unique requirements, our Mold Design product offers the flexibility of choosing between a single cavity or multiple cavities. A single cavity mold is ideal for specialized, low-volume production or for parts that require absolute consistency. Multi-cavity molds, on the other hand, are suited for high-volume production, allowing for multiple parts to be produced in a single cycle, thereby increasing efficiency and reducing overall production costs.

When it comes to the lead time, we are committed to delivering speed without compromising on quality. Our streamlined process ensures that from the initial design phase to the final product delivery, our clients can expect a turnaround time of just 2-4 weeks. We understand the importance of time in the market, and our dedicated team works diligently to ensure that your mould is designed, tested, and ready for production within this timeframe.

The backbone of our Mold Design product is the sophisticated CAD software we use. This powerful tool enables our designers to create highly accurate and detailed mold designs, ensuring a perfect fit for the intended application. The software's precision allows for the intricate and complex geometries often required in plastic injection mold parts, resulting in molds that produce parts with exceptional accuracy and surface finish.

Our commitment to customization is reflected in the mold sizes we offer. Each mold is customized to suit the specific requirements of the client's product. Whether you need a compact mold for small, intricate parts or a larger mold for bigger components, our team is equipped to design and manufacture molds that are tailor-made to your specifications. This level of customization is essential to fulfilling the diverse needs of the manufacturing sector and ensuring that our clients receive molds that are perfectly suited to their production processes.

The application of our Mold Design product spans across various industries. In manufacturing, the precision and quality of the mould are paramount, and our product delivers on both fronts. Every mold is designed with the end-use application in mind, ensuring that it can withstand the rigors of the manufacturing process and consistently produce parts that meet or exceed industry standards. Whether it's a mold for consumer electronics, automotive parts, or any other industry, our Mold Design product provides the reliability and performance that manufacturers need.

In conclusion, our Mold Design product stands out in the market for its precision, customizability, and efficiency. With a focus on single or multiple cavity molds, rapid lead times of 2-4 weeks, utilization of advanced CAD software, and a commitment to producing molds of any size, we offer a comprehensive solution for manufacturing high-quality plastic injection mold parts. Our moulds are not just tools; they are the foundation of your product's success in the competitive manufacturing landscape.

| Attribute | Details |

|---|---|

| Mold Size | Customized |

| Production Volume | Small To Large Scale |

| Tolerance | 0.01mm |

| Material | Steel |

| Cavity Number | Single Or Multiple |

| Mold Life | 100,000-1,000,000 Shots |

| Surface Finish | Polishing |

| Design Process | Injection Molding |

| Lead Time | 2-4 Weeks |

| Product Type | Industrial Design |

The realm of manufacturing is rife with scenarios where precision and customization take the forefront. In such settings, the use of custom mold parts, particularly those originating from the industrious hubs of China Fujian, becomes indispensable. Enterprises that require bespoke components, with an assurance of quality certified by ISO, find themselves turning to products like our custom mold parts designed meticulously to fit their unique applications.

Our mold design product is emblematic of exacting Chinese craftsmanship, with our place of origin being China Fujian, a testament to the region's manufacturing prowess. We cater to a diverse array of industries, ensuring that each custom mold part meets the rigid tolerance of 0.01mm. This level of precision is critical in applications where even the slightest deviation can lead to significant operational inefficiencies or safety concerns.

Given the intricate nature of these applications, we maintain a stringent design process that revolves around injection molding, a technique that guarantees the durability and integrity of the custom mold parts. The surface finish of each part is achieved through careful polishing, reflecting the aesthetic and functional standards that our clients expect. To facilitate the design process, we employ advanced CAD software, ensuring that every custom part is rendered with accuracy before it ever takes physical form.

Understanding the urgency of operational demands, we commit to delivering these custom mold parts within a 30-day timeframe. Our packaging details promise neutral packing, ensuring that the products arrive in pristine condition, ready for immediate use. We operate on a minimum order quantity of 100, with a price point set at 1, making it accessible for businesses to procure high-quality molds without undue financial strain. The payment terms are clear and straightforward—transactions are conducted through TT, ensuring a smooth process from order to delivery.

Our supply ability soars beyond 10,000 pieces, a testimony to the scalability we offer our clients. This robust supply chain capability ensures that even as demand fluctuates or scales, we remain a reliable partner in providing the custom mold parts necessary for continuous operation. For businesses seeking a steadfast supplier for their mold design needs, our product presents an optimal synergy of quality, efficiency, and customization, all hailing from the renowned manufacturing landscape of China Fujian.

Place of Origin: China

Certification: ISO

Minimum Order Quantity: 100

Price: 1

Packaging Details: Neutral Packing

Delivery Time: 30 days

Payment Terms: TT (Telegraphic Transfer)

Supply Ability: 10000+ pcs per week

Quality Control: Strict Inspection And Testing

Mold Life: 100,000-1,000,000 Shots

Mold Cost: Varies Depending On Complexity

Surface Finish: Polishing

Design Process: Injection Molding

Keywords: Mould, Plastic injection mold parts, custom mold parts

Our Mold Design Product Technical Support and Services are dedicated to ensuring your success with our software. We provide a comprehensive suite of services to assist with any technical challenges you may encounter during the design process. Our support includes access to a knowledge base with articles, how-to guides, and troubleshooting tips to help you navigate through common issues.

If you require more personalized assistance, our experienced technical support team is available to provide guidance. They can help with software functionality, optimization for performance, and provide best practices for mold design to enhance your productivity. Additionally, we offer training sessions to improve your team's proficiency with our product.

We also conduct regular updates and maintenance to ensure our product operates at peak performance with the latest features. Our commitment is to provide you with the highest level of support and services to facilitate the creation of high-quality mold designs.

Our Mold Design products are meticulously packaged to ensure their safe arrival at your destination. Each mold is encased in a protective foam layer to cushion it from any impacts during transit. The foam is then placed inside a sturdy cardboard box that is specifically designed for the dimensions of the mold, minimizing movement and further enhancing protection.

Before shipping, we seal the box with heavy-duty tape and label it with all necessary handling and care instructions to ensure that the carrier transports your product with the utmost care. We also include a packing slip with product details and any additional information required for smooth customs clearance, in case of international shipping.

We offer various shipping options to meet your budget and delivery time requirements. Our standard and express shipping services ensure that your Mold Design product is delivered to you promptly and securely. Upon dispatch, you will receive a tracking number so you can monitor the progress of your shipment until it safely arrives at your door.

Q1: What is the origin of your mold design products?

A1: All of our mold design products originate from China, ensuring quality manufacturing and design principles adhering to the industry standards.

Q2: Are your mold design products certified?

A2: Yes, our mold design products are ISO certified, indicating that they meet international standards for quality management and consistent performance.

Q3: What is the minimum order quantity for your mold design products?

A3: The minimum order quantity for our mold design products is 100 pieces, which allows us to provide you with the best value and ensures quality control throughout the production process.

Q4: Can you provide the pricing details for your mold design products?

A4: Certainly, the price for our mold design products is set at 1 unit per item. For larger orders or bespoke designs, please contact our sales team for a detailed quotation.

Q5: How are the mold design products packaged for delivery?

A5: Our mold design products come in neutral packing to ensure safe transportation and to maintain the integrity of the product from our facility to your doorstep.

Q6: What is the typical delivery time for your mold design products?

A6: The standard delivery time for our mold design products is approximately 30 days. This timeframe allows for meticulous quality checks and safe packaging for shipment.

Q7: What are the payment terms for purchasing your mold design products?

A7: We accept payment through TT (Telegraphic Transfer), which is a secure and efficient method of payment for both parties involved in the transaction.

Q8: What is the supply ability of your company for mold design products?

A8: Our supply ability for mold design products is more than 10,000 pieces per month, ensuring we can handle large orders and maintain a steady supply chain.