Dongguan Zhaoyi Hardware Products Co., LTD. |

|

Verified Suppliers

|

|

Precision Plastic CNC Milling

Product Details

Poduct Name: Precision Plastic CNC Milling

Material: Plastic

Surface Treament: As Machined

Size: Customized

Process Machine: CNC milling machine

Trade Terms: EXW

Proofing Time: 5-10 Days

Production Time: It depends on the structure and qty of the parts

Tokerance: ±0.05mm

Application: Equipment

Origin: Dongguan, China

High Precision OEM CNC Machining Parts Supplier

| Service | CNC Turning, CNC Milling, Laser Cutting, Wire Cutting, Stamping, Electric Discharge Machining (EDM), etc. |

| Materials | 1). Aluminum: AL 6061-T6, 6063, 7075-T, etc 2). Stainless steel: 303, 304, 316L, 17-4(SUS630), etc 3). Steel: 45#, Q235, Q345B, etc 4). Titanium: TA1, TA2/GR2, TA4/GR5, etc 5). Brass: C36000 (HPb62), etc 6). Copper, bronze, POM, Acrylic, PC, etc |

| Surface Treatment | Sandblasting, Anodize, Zinc/Nickl Plating, Polish |

| Processing Technology | CNC machining parts, turning/milling process |

| MOQ | 1pcs |

| Lead Time | Sample: 3-10 days Mass Production: within 10-25 days after receiving the deposit |

| Package | 1) pp bags + carton or wooden case 2) according to customers' requirements 3) negotiable |

| Payment Terms | T/T, Paypal |

Main Advantages of CNC Milling

There are countless reasons why CNC milling technology is widely regarded as one of the most reliable ways to produce parts from various materials.

Let’s look at some of the most significant advantages of this technology below:

Unmatched Precision

The accuracy and precision with which CNC milling can operate are second to none in the entire world, which is why it is used in fields like aerospace and medicine that need each detail to be executed without even the slightest error.

Using a digital template and autonomous machining that CNC milling is based on, human error is eliminated from the manufacturing process, and the accuracy that is produced is as near perfection as is possible today.

Longevity

Because the CNC milling machines can run practically on autopilot and don’t require much human involvement in the process, they can run without stopping for days, producing parts consistently and with the same precision.

The only time that CNC machines need to be stopped is when they require regular maintenance or if there is an accident.

Fewer Personnel

The automated process that CNC milling is based on also means that fewer people are required to monitor and run it, which results in not only increased efficiency but in reduced production costs as well.

A few skilled specialists are all that’s needed to oversee the entire process, which means better cost-effectiveness for the end client.

Advanced Possibilities

Because of the advanced automation software and design software, CNC milling machines can outperform the most skilled technicians operating manual machines, even if the manufacturing process itself is similar.

This means not only better consistency and the elimination of human error but also the ability to produce designs that are much more complex, with varying sizes, shapes, and even textures.

Consistency

Since the process behind CNC milling is mostly automated, it produces remarkable consistency, even if personnel managing the tools changes.

Once a master file of the design is created, it can be used to create an unlimited number of copies that will all be of the same quality and without any deviations. Each part will be a perfect match to the previous version, which is very hard to achieve even for the most skilled manual operators.

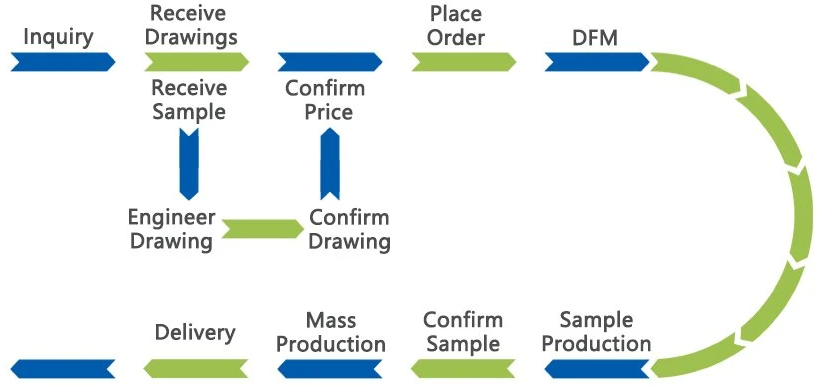

CNC Milling Flow

FAQ

Q: What is the shipping method?

A: For engineering samples we will send out by international

express service or by air. For mass-production, it depends on

weight and volume, usually by air or by sea.

Q: Is it possible to know how are my products going on without

visiting your company?

A: Yes. We will offer a detailed production schedule and send

weekly reports with digital pictures and videos which show the

production process.

Q: If you make poor quality goods, will you refund our fund?

A: As a matter of fact, we won't take a chance to do poor quality

products. Meanwhile, we manufacture goods quality products until

your satisfaction.

Q: How to contact sales person?

A: Please send us inquiry or e-mail directly. Or you can talk with

us online by trademanager, skype, whatsapp, WeChat, etc.

Q: What's kinds of information you need for a quote?

A: Kindly please provide the product 2D drawing with PDF or DWG

format and 3D drawings with STEP or IGS or X_T format, and other

requirements like: surface treatment, quantity...etc.