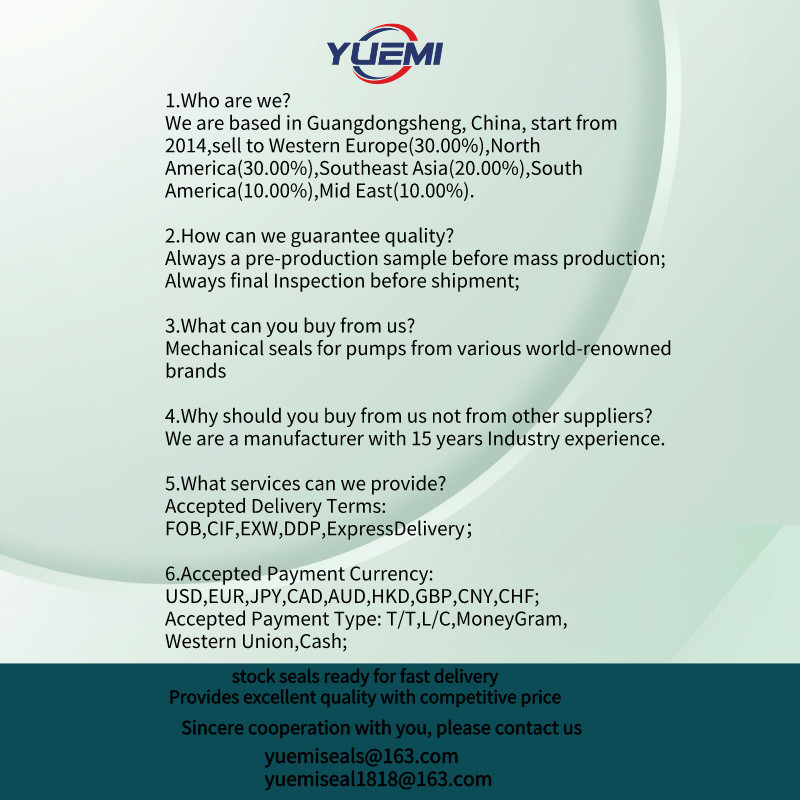

YUEMI |

|

Verified Suppliers

|

|

| MODEL | D2 | D3 | D7 | L1 | L3 | L4 |

| SB-10 | 11.0 | 27.0 | 23.0 | 10.5 | 7.5 | 4.0 |

| SB-12 | 14.0 | 32.0 | 25.0 | 10.2 | 9.0 | 5.0 |

| SB-16 | 18.0 | 41.0 | 31.0 | 11.8 | 10.0 | 5.0 |

| SB-16A | 18.0 | 41.0 | 35.0 | 16.5 | 9.5 | 9.0 |

| SB-17 | 18.5 | 35.0 | 30.0 | 16.0 | 9.5 | 9.0 |

| SB-20 | 21.0 | 45.0 | 35.0 | 11/16.3 | 11.5 | 5/10.3 |

| SB-25 | 26.4 | 52.0 | 41.3 | 19.0 | 12.0 | 11.0 |

| SB-30 | 31.0 | 58.0 | 48.0 | 16.5 | 12.5 | 8.5 |

| O-Ring Mechanical Seals | |

Temperature: -30ºC to 200ºC, dependent on the elastomer Pressure: Up to 5 bar Speed: Up to 15 m/s End play/axial float allowance: ±0.1mm Size: 10mm to 30mm | Stationary Ring: Plastic Carbon, Carbon, Ceramic Rotary Ring: Ceramic, Silicon Carbide Secondary : NBR/EPDM/FKM |

Preperation:

1. Shaft Outside Diameter is within tolerance +-0.05mm

2. Shaft run out <0.1mm

3. Shaf end float <0.13mm

4, No sharp edges on the shaft over the o ring

Note:

During the installation,don't scratch or damage the o ring.lf

anything is damaged,please contactwith Us to replace a new one.

Installation in strucstions:

1. The full set of cartridge seal is cleaned and exactly passed

leakage examine before sale.Inorder to avoid damage,don't

disassemble and clean the parts again before fixing.

2 The fitting allowance between the seal and shaft is dl h6 0.8,and there should be leading-inedge at the end of shaft.The outside diameter of shaft at the position of screw should be 01 0.2mm smaller,resisting the screw over-tighten.Lubricate the shaft with oil

3. Place the cartridge seal into the pump chamber,then:

A: Tighter four screw bolts of flanges,ensuring the medium leading

in hole"G"at the top Position

B : Tighter four set screws and position the shaft sleeve on the

shaft.

C: Remove four gauge plates.Please keep them and they wil be used

in future installation and

disassemble.

D: Connect the medium lead_in pipe with hole"G"in order to flush

away the friction heat and

flushing the seal chamber when pump running.

Note:

ter complete the installation,turning the shaft by hand to check

for the rotationi he shat could not rotate smoothily,seal had been

improperly installed.

We would like lo sincerely ooperale with Clients to supply high qually products and senice We beleve in establishing a long:erm cooperalive relalionshipis lhe key to suceess