Active Member

|

[China]

Address: Room 805-806 Business building, NO.358 Xinnan East Road, Kunshan, Jiangsu

Contact name:Flavio

SUZHOU RILANT TECH CO.,LTD. |

|

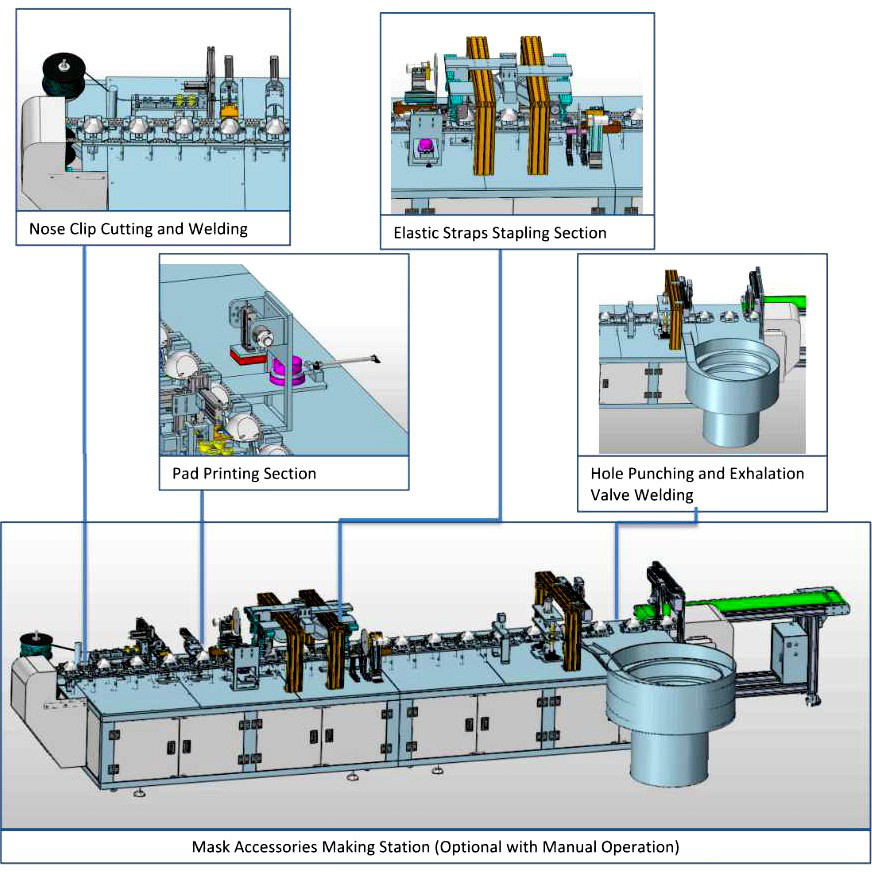

Full Automatic High-Speed Cup N95 Mask Making Machine With Breathing Valve

1, Machine Specifications

Integral design, from raw material loading, mask cup body shaping-welding-stamping, automatic nose bridge welding, automatic printing logo, automatic earloop spot welding / stapling, automatic punching edge, automatic breathing valve welding and other processes are automatically completed, so as to achieve automatic mask finished products, the whole machine to achieve automation. Constant temperature induction sticks nose bridge strip, smooth incision, no damage on the surface, strong fitting. Automatic printing logo, efficient and fast, clear pattern.Automatic two-way earloop installation, adjustable length, firm and strong tension.

The equipment is used to produce a disposable non-woven mask. The equipment is mainly composed of feeding, shaping, welding, cutting, connecting and transferring, polar ear welding, blanking and stacking, etc. In addition to manual feeding, the whole process from the raw material feeding to the nose rib insertion edge cutting finished product stacking is fully automatic operation. The machine can be combined by one pull one or one pull two pole ear welder to meet different production capacity requirements.

| Model | KS-C95P | Qualified rate | ≥95% | |

| Product Type | Cup mask | Compressed Air Flux 200L/min | 200L/min | |

| Specification | 150mmx 130mmx50mm (can be customized) | Condition | New | |

| Speed | 15-25 pcs/min | Gross Weight | 2700KG | |

| Material | Nonwoven fabric Melt-blown | Ultrasound | 20KHZ | |

| Layers | 3-6 Layers | Dimension | 8500*1250*1050mm | |

| Hot pressed cup type | Customized according to samples | Power | 14.5KW | |

| Ear-loop Fixed method | Stapling type, welding type | Power supply | 380V/50Hz | |

| Control panel | 10° control panel | Area | 12000x2500x1800mm | |

| Air pressure | 0.6MPa | |||

2, Machine feature

1.Fully automatic working process for material loading, hot press cup forming, ultrasonic cup contour welding, cup waste cut away, and collection of finished cups.

2.Automatic pressor control with guaranteed consistency of cup forming quality. 3.Automatic waste material detaching and collecting after dia cut.

4.With high productivity of 25 cups per minute.

5.With a 10-inch color computer operation panel.

6. The total power of the cup forming station is 9.5KW.

7.The machine equipped with emergency stops.

8. Each machine includes one cup mold, customized mold size and shape is acceptable.

3, Machine Pictures

Q1. Do you provide OEM or ODM service?

A: Yes, we have 4 designers for developing new products according

to your requirements.

Q2. What's the lead time?

A: Usually within 30 days, it would be longer for new designs.

Q3. What's the After-Sales Service?

A: Engineers available to service machinery overseas.

A: We provide 15 days of free accommodation for technical training,

till your engineer operate the machine well.