Nanjing Mankate Science & Technology Co., Ltd. |

|

Verified Suppliers

|

|

NJMKT High bonding power bond adhesive Cracking filling high loading Epoxy Resin

Nanjing Mankate passed ISO quality system certification and was awarded the honor of China Famous Brand Product, covered by Ping An insurance company.

Main Components: Modified epoxy resin, nanomaterials, other additives

Component A: Component B =2:1

Feature:

*Anti-aging and anti-medium (acid, alkali, water)

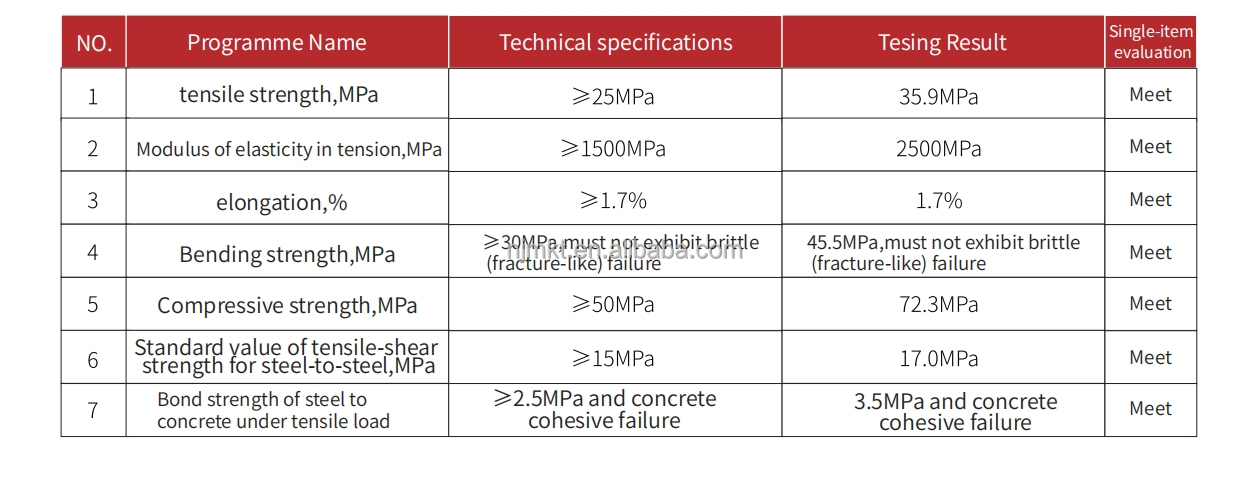

*Excellent toughness and good impact resistance after cured, high tensile strength of 27Mpa

*High permeability, even for 0.1mm crevice

*Very good resistance to age, medium( acid, alkali and water)

*No volatile solvent, nearly no shrink during cure

*Safe and non-toxic, easy construction process

*Transparent and colorless, no irritating smell, environmental non-toxic

*Its strength is higher than the concrete, and the degree of fusion with the concrete is perfect, aging resistance is for more than 50 years

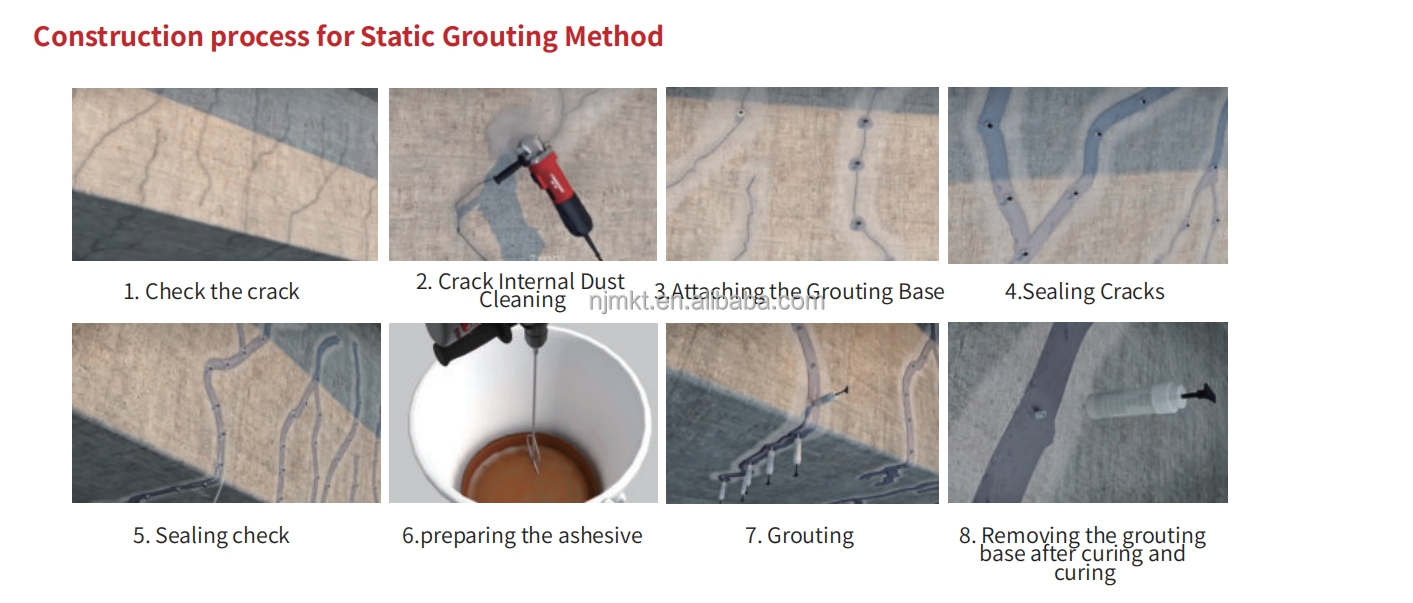

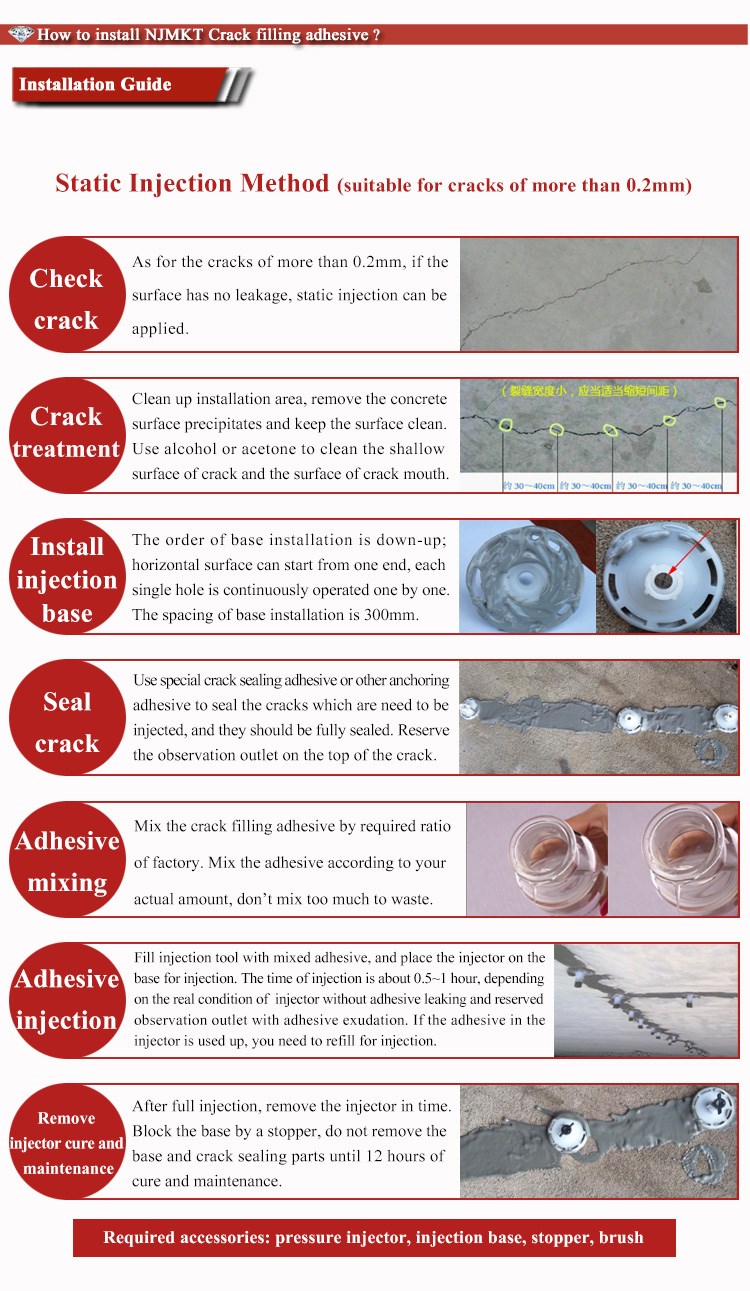

Static Injection Method (suitable for cracks of more than 0.2mm)

1. Check crack: As for the cracks of more than 0.2mm, if the surface has no leakage, static injection can be applied.

2. Crack treatment: Clean up installation area, remove the concrete surface precipitates and keep the surface clean. Use alcohol or ace tone to clean the shallow surface of crack and the surface of crack mouth.

3. Install injection base: The order of base installation is down-up; horizontal surface can start from one end, each single hole is continuously operated one by one. The spacing of base installation is 300mm.

4. Seal crack: Use special crack sealing adhesive or other anchoring adhesive to seal the cracks which are need to be injected, and they should be fully sealed. Reserve the observation outlet on the top of the crack.

5. Seal check: Check the sealed cracks to ensure there is no air leakage.

6. Adhesive mixing: Mix the crack filling adhesive by required ratio of factory. Mix the adhesive according to your actual amount, don't mix too much to waste.

7. Adhesive injection: Fill injection tool with mixed adhesive, and place the injector on the base for injection. The time of injection is about 0.5~1 hour, depending on the real condition of injector without adhesive leaking and reserved observation outlet with adhesive exudation. If the adhesive in the injector is used up, you need to refill for injection.

8. Remove injector, cure and maintenance: After full injection, remove the injector in time. Block the base by a stopper, do not remove the base and crack sealing parts until 12 hours of cure and maintenance.

Required accessories: pressure injector, injection base, stopper, brush

High-pressure Grouting Method (suitable for all cracks)

1. Clean treatment: Check and analyze the leakage carefully to determine the position and spacing of grouting holes. Clean up installation area, remove the concrete surface precipitates and keep the surface clean.

2. Drill holes: Drill holes by electric hammer drilling tools along the crack, the diameter of drill bit is 14mm, the angle of drilled hole is better to be ≤45℃, the depth of drilled hole is ≤2/3 of structure thickness, the drilled hole must be through the crack. But the structure (except post wall grouting) should not to be drilled through. The spacing between drilled hole and crack is ≤1/2 of structure thickness. The spacing of drilled hole is 20cm~60cm.

3. Embed nozzle: Install the grouting nozzle (also known as water-sealing needle) in the drilled hole, and use special hexagon wrench to tighten to make sure there is no gap around the grouting nozzle and drilled hole, no leakage.

4. Wash crack: Inject clean water to grouting nozzle at a pressure of 3Mpa with high pressure washing machine to observe the water leakage condition, and wash up the dust in the crack.

5. Seal crack: When washing crack if you find the water leaking crack surface, use fast-cure cement to seal it in order to prevent adhesive leaking during grouting chemical adhesive.

6. Grout adhesive: Use high pressure grouting machine to fill chemical adhesive into holes. The order of vertical surface grouting is down-up; horizontal surface can start from one end, each single hole is continuously operated one by one. When the neighbor hole starts to pour out, keep the pressure for 3~5 minutes and stop grouting, then grout the neighbor hole.

7. Remove nozzle: After finish adhesive grouting, check there is no leakage then remove the nozzle or knock out the exposed nozzle. Clean up excess leaked and cured adhesive.

8. Sealing treatment: Repair and seal the mouth of crack grouting by fast-cure cement.

Required accessories: grouting machine, water-sealing needle, brush, measuring spoon

Application:

*Suitable for crack repair in concrete project

*Widely used for concrete interior defects(honeycomb, porosity ) injection repair,

*Hollowing wall and floor tile filling

![]()

|  |  |

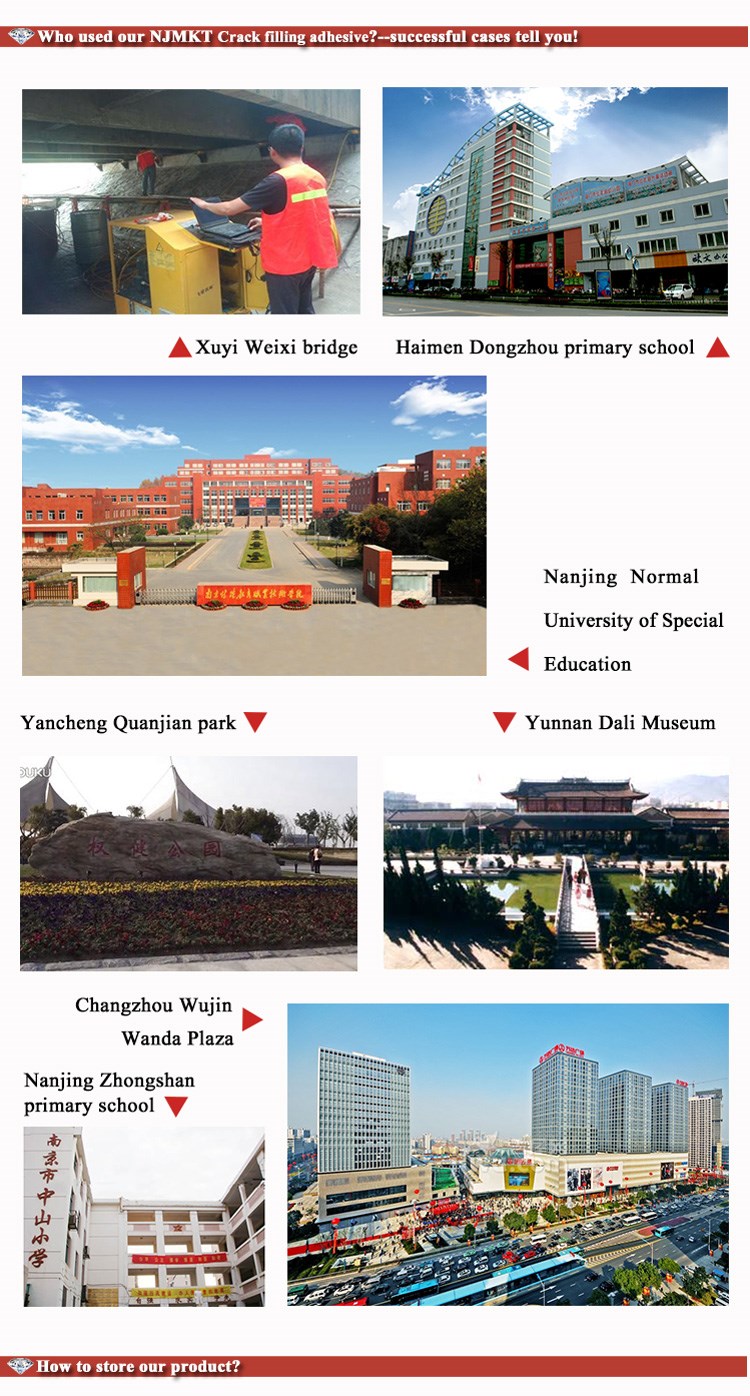

Nanjing Mankate, founded in 2003, is a high-tech enterprise that specializes in researching, developing, manufacturing and selling a full range of anchoring and fixing systems, products and accessories for building reinforcement in construction industry.

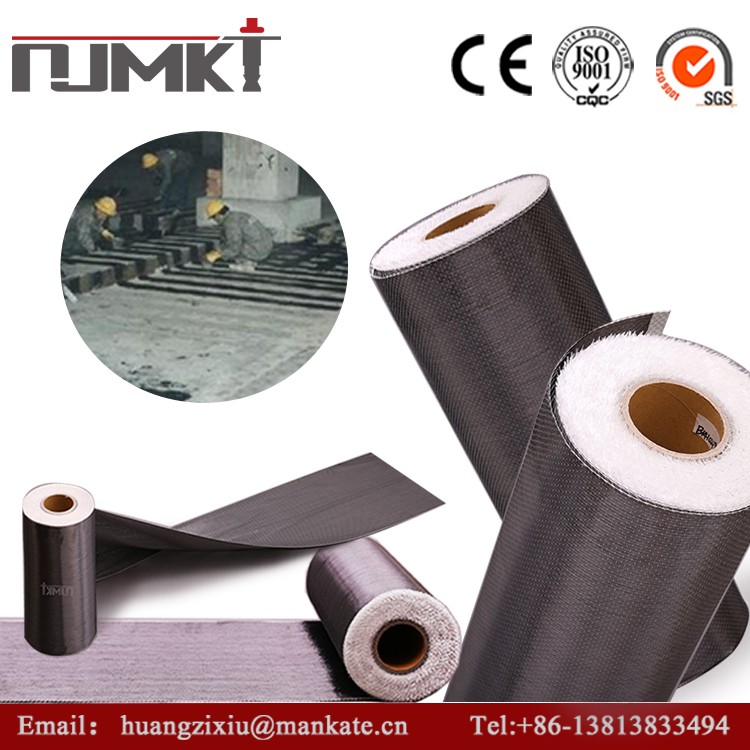

Our company develops and manufactures more than 10 kinds of series products: undercut anchors, self-undercutting anchors, undercut panel anchors, adhesive anchors, carbon fiber sheet, carbon fiber plate, prestressed anchorage device, carbon fiber adhesive, crack sealing adhesive, steel bonding adhesive, anchorage adhesive, crack filling adhesive, and so on.

Our company strictly adheres to domestic and international standards to manufacture and manage, and we have received many honors. Our products was named as "Green Products of China Building Materials" in 2004, and awarded the honor of "Jiangsu AAA Quality and Integrity of Brand Enterprise" and "National Integrity of Corporate Membership" by CQSA in 2007. The trademark of Mankate has been recognized as "China Famous Trademark" in 2008. Nanjing Mankate passed ISO 9001:2008 quality system certification in 2011, and obtained honorary titles of "Jiangsu High Quality Products" and "China Famous Quality Products" in 2016, and so on.

NJMKT steadfastly holds on the belief of "product sale is just the first step", takes the benefit of clients as our starting point, appoints professional workers and technical engineers to inspect on construction site and communicate with construction party to help to detail the design plan, calculate overloading capacity of reinforcement materials, etc. NJMKT customizes various specifications of products according to every project requirements in the case of without affecting material performance.

FAQ

1. Where is your factory located? How can I visit there?

Factory Address: No.3 Jinhua Road, Guli Industrial Park, Jiangning, Nanjing City, Jiangsu Province, China

Office Address: Room306-307, West District of WandaJinjie, No. 291 Shuiximen Road, Nanjing City, Jiangsu Province, China

Tel: +86 (0)25-86651110 / 4008-945-118

Mobile: 13813833494/13813882444

Warmly welcome domestic and international customers to visit us!

2. Are you a manufacturer?

Yes, we are. We have our own factory to manufacture customized products according to customers' need. We are specialized in developing and manufacturing constructions reinforcement materials for more than ten years.

3. Is your sample free?

Yes, our sample is free but the shipping charge will be on your side.

4. How to get the quotation?

We have a full range of products with different sizes and specifications. Please offer us project information with details, material and size requirements of products or send us design drawing for our team to make complete solutions, then we could supply a most reasonable and favorable quotation for you.

5: What is your payment terms?

We prefer 100% T/T. For other payment terms we could discuss for every case.

6: How long is the lead time (producing time) ?

It depends on your order quantity and our factory production schedule. Usually we have a large stock of standard size products, and we can arrange and deliver the goods asap.