PingYang DEM Auto Parts Factory |

|

Verified Suppliers

|

|

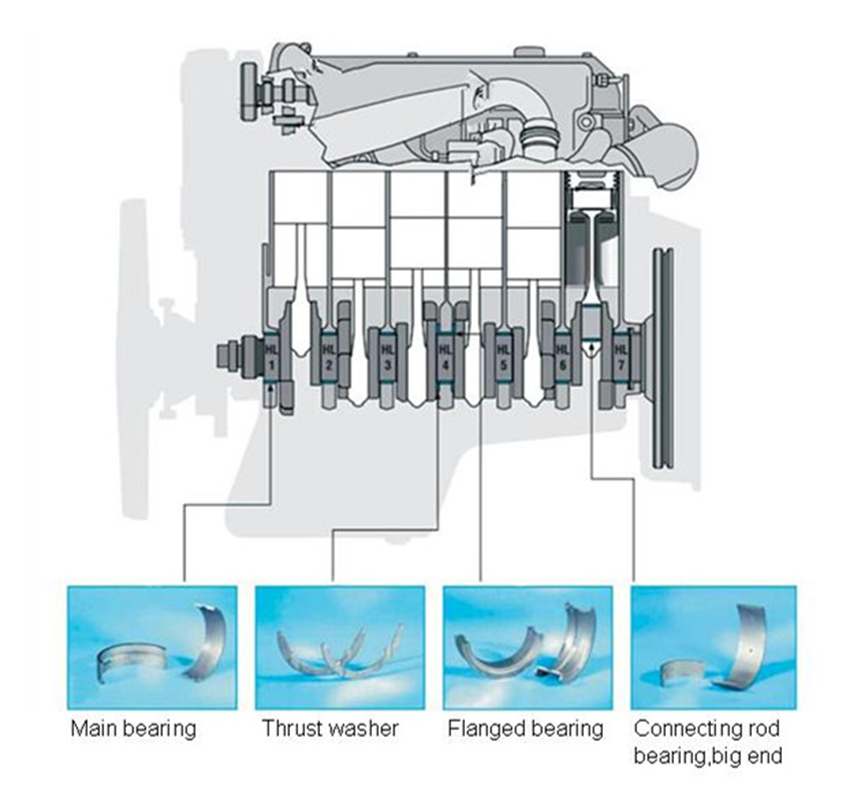

Wear Resistant Engine Main Bearing 20-156/5A For Fiat PUNTO 60 1.2S 10pcs

Product Specification

| Model | Wear Resistant Engine Main Bearing 20-156/5A For Fiat PUNTO 60 1.2S 10pcs |

| Brand | TAJHO |

| Weight | 1.22kg/PC |

| Material | Aluminum-based |

| SIZE | Standard |

| Application | Machinery parts/Automobile Parts |

| Quality | ISO 9001:2008 ISO/TS16949 standard |

| Precision | 0.013mm |

| Service | OEM available |

Product Introduction

The manufacturing process of bearing shells usually includes steps such as material selection, precision machining, coating, and heat treatment. Through precision machining and coating technology, the surface smoothness, wear resistance, and lubrication performance of bearing shells can be improved.

In order to improve the wear resistance and lubrication of bearing shells, it is often necessary to treat their surfaces. Common surface treatment methods include galvanizing, spraying coatings, and applying lubricating layers.

Product Technology

To improve the surface hardness and lubrication performance of bearing shells, coating technology is often used. Coatings can be metal coatings, ceramic coatings, or composite coatings. By using high-temperature spraying or physical deposition technology, the coating material is evenly covered on the surface of the bearing shell.

Bearing pads are important components in the field of mechanical engineering, used to support and position rotating shafts, and reduce friction and wear. Manufacturing high-quality bearing shells requires precise process and material selection. Bearing shells are usually made of metal materials, such as copper alloy, aluminum alloy, etc.

Sliding pad bearing: The upper ring is composed of sliding pads, suitable for high-speed and high load conditions, and can reduce friction heat and wear.

Elastic bearing shell: The upper ring is made of elastic material, which can absorb impact and vibration to a certain extent, improving the reliability of the equipment.

As an indispensable and critical component of mechanical equipment, in the transmission system of railway vehicles, bearing pads are used to support and guide wheel axles, ensuring smooth train operation and reducing wear and tear on wheels and tracks