Sichuan Vacorda Instruments Manufacturing Co., Ltd |

|

PTFE magnetic float liquid level switch

Product features

1.Long life span, stable and reliable operation, easy installation, almost no maintenance

2.Independent of mediums’ physical and chemical status

3. Appliable for all kinds of bad medium environment with density ≥0.5g/cm³

4. Available for interface detection of mediums with two different densities

5. Wide application range. Pressure 0~PN160 (max. up to PN320), temperature -40~+150 ° c

Product Parameters

(1) High temperaturre type: | ≤150℃ |

(2)Protection grade: | IP65 |

(3)Working temperature scope: | -40℃~80℃ -40~120℃ |

(4)Anti-explosion grade: | EXia EXd |

(5)Installation Angle : | ≤±25° |

| (6)Installation Type: | DN50/RF/PL(HG/T20592-2009) |

| (7)Float Diameter: | PN≤6.3MPa,float diameter=45mm; PN>6.3MPa,float diameter=65mm |

(8)Medium Density: | ≥0.5g/cm3 |

(9)Connection : | M20*1.5 female thread |

(10)MAX Installation Depth: | 6000mm |

Features

1, long life span, stable and reliable operation, easy installation, almost no maintenance

2, none influence of measured medium in physical and chemical state. Eg: medium electrical conductivity,

dielectric constants, foam, pressure, temperature, evaporation, boiling, bubbling effect etc, .

3, choose appropriate material can be used in a variety of bad media environment with densities ≥ 0.5G/CC ;

4,-interface measurement with two media of different density control;

5,wide range of application. Pressures from vacuum to PN160 (special up to PN320), temperature -40~+150 ° c;

6,design, explosion-proof, suitable for explosive environments;

7,UHKG controller can be used to control the upper and lower liquid level.

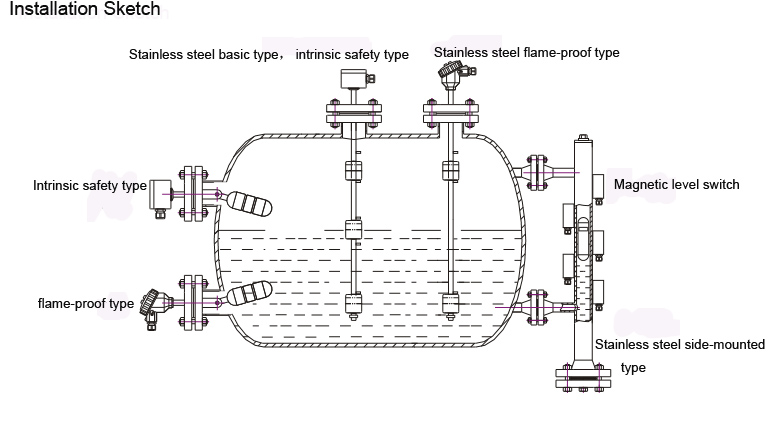

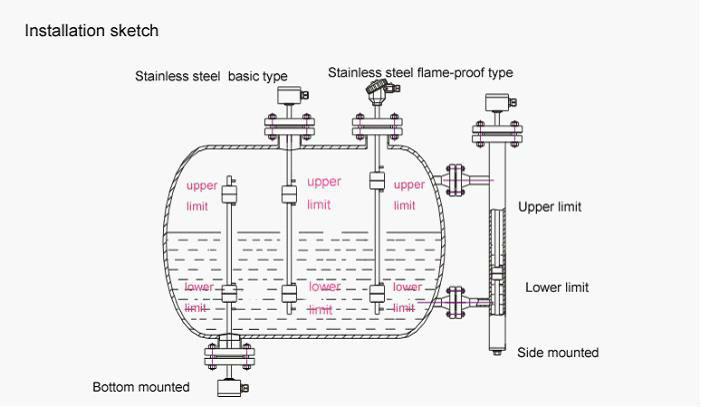

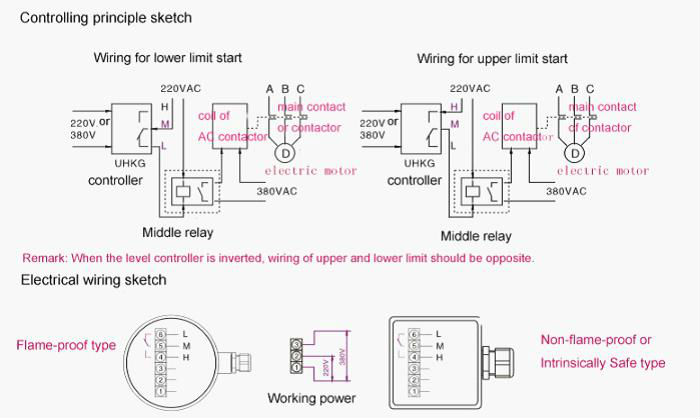

Operation:

Two control method of one magnetic float level gauge:

1,the upper limit—users select the normally open contact connection: the machine starts when the liquid level reaches the controlled upper limit and the node closes.

When the liquid level reaches the controlled lower limit and the node opens, the machine stops. (eg. When the liquid flows out the pump);

2,the lower limit—users select the normally closed contact connection: the machines starts when the liquid level reaches the controlled lower limit and the node closes.

When the liquid level reaches the controlled upper limit and the node closes, the machine stops. (eg. When the liquid flows in the pump);

Technical Data:

| Max insert depth | L=6m(>6m customize) |

| Max control scope | L-120mm |

| Min control scope | 50mm(<50mm customize) |

| Medium density | >0.5g/cm3 |

| Working pressure | PN2.5~ PN160(Max pressure PN320) |

| Working temperature | -40~80 °C, -40~120 °C, -40~150 °C (250°C customize ) |

| Float diameter | D28~D120(depending on pressure and density) |

Installation type | Flange: DN40~DN150 |

| Flange standard: HG/T20592~2009 | |

| (pressure>PN25, Flange>DN125) | |

| G2'' thread | |

| Other method (consulting) | |

| Maximum switch frequency | <1×105 |

| Inaccuracy | ±8±2mm |

| Working power supply | 220VAC/380VAC |

| Max voltage of switch | <250VAC |

| Max current of switch | 5A |

| Installation angle | < ±25° |

| Wiring box | M20×1.5 female thread |

| IP grade | IP65 |

| Explosion-proof grade | Exd II CT6Gb |

The magnetic suspension level gauge and the container to be measured form a communicating device, so that the liquid level between the container to be measured and the measuring tube body is equal. When the float in the measuring tube of the liquid level gauge changes with the measured liquid level, the magnetic body in the float interacts with the magnetic body in the color code displayed on the display bar and reverses, so that red means there is liquid and white means no The purpose of accurately displaying the liquid level on the spot.