Dongguan Ming Rui Ceramic Technology Co.,ltd |

|

Low Friction Zirconia Ceramic Valve Block Corrossion Resistant

Tag key words : Ceramic Valve Block

Mingrui Currently developing a way to use high-precision and high wear resistance of ceramics as a faucet control valves, greatly improving the quality of faucet, price and life. But this newly developed products are still used by conventional sealing rubber and other soft materials as ceramic pad control valve at the bottom of the leak components, limiting its bearer can not reach the limit, it is easy due to the force generated by ectopic defects.

Figure 1 and Figure 2, the valve device body 10 generally comprises a faucet, ceramic control valve 20 and the rotary dial 13. Faucet body 10 has a bearing ring surface 11 and chamber 12 is screwed. Ceramic control valve 20 groups located in the faucet body 10, and by the top rotary dial the actuator 13.

Such conventional ceramic control valve 20 includes a cylindrical body 21, the shaft 30, the spin valve block 35, the static valve block 39, 42 and the pressure auxiliary rotary sealing pad 46.

Manufactured from the highest purity Zirconia, our zirconia Rotors provide the NMR spectroscopist with the ultimate alternative for analysis of solid samples. The need to solvate solid samples is eliminated. They are available for most of the present solid state NMR spectrometers.

Our are carefully examined for material irregularities by various methods before and after the precision machining process.

High precision (which becomes a necessity for proper spinning performance) is maintained in the manufacture of the end caps. Most Zirconia end caps are fitted with o-rings for better sealing. Some caps have axial holes for venting.

Mingrui Ceramic utilize super-precision, wear-resistant ceramic stators of silicon nitride or zirconia. MAS spinner materials must be chosen carefully based on background signals and temperature ranges. Ceramic Valve Block of various materials are available to provide fast spinning with limited background problems.

Advantages of Ceramic Valve Block

About Ceramic Valve Block :

Zirconia materials are used in very high wear applications under very high pressure requiring improved fracture toughness and stiffness over alumina. Ceramic Valve Block is noted for its high strength, toughness, wear and thermal properties. Its high material cost usually warrants its usage extending longer life and reduce down time where alumina fails in this applications.

During manufacture, the zirconia powder is combined with oxides such as Yttria, magnesia or tetragonal and the material is said to be partially stabilised or even it can be fully stabilised if required, varying the composition allows different properties to be enhanced.

Yttria (Y-PSZ) stabilised zirconia Ceramic Valve Blockare mainly used for excellent wear resistance up to 400’C temperature while Magnesia (MgO-PSZ) zirconia are very good at high temperature offering excellent thermal shock and also wear resistance. Y-TZP Zirconia material has tetragonal in structure and has the highest flexural strength of all the zirconia based materials. The fine grain size of Y-TZP lends itself to be used in cutting tools where a very sharp edge can be achieved and maintained due to its high wear resistance. The fine grade size leads to a fully dense with excellent mechanical strength, corrosion resistance, impact toughness, thermal shock resistance and very low thermal conductivity.| Magnesia ZrO2+MgO | Yttria ZrO2+Y2O3 | Tetragonal ZrO2+ YTZP | Toughened ZrO2+Al2O3 | |

|---|---|---|---|---|

| Density- g/cm3 | 5.70 | 6.02 | 6.04 | 5.5 |

| Water Absorption-% | 0.00 | 0.00 | 0.00 | 0.0 |

| Compressive strength-Mpa | 1700 | 2000 | 4000 | 2000 |

| Flexural Strength – Mpa | 600 | 950 | 2500 | 1800 |

| Fracture Toughness- Mpa.m1/2 | 8-9 | c | 10 | 8 |

| Young Modulus-Gpa | 250 | 205 | 210 | 220 |

| Max. Temperature °C | 1000 | 1000 | 1000 | 1000 |

| Thermal Conductivity-W/m’K | 2.5 | 2.0 | 2.0 | 6.0 |

| Thermal Expansion of Coefficient linear -10-6/°C | 10.0 | 10.0 | 11.0 | 9.0 |

| Volume resistance – Ohm cm | 1010 | 1010 | 107 | n/a |

| Dielectric Constant 1MHz | 28 | 8.3 | 2.4 | n/a |

| Dielectric Strength – kV/mm | 9.0 | 9.0 | 8.7 | n/a |

| General Characteristics of Materials: | ||||

| Characteristic | Ceramics | Metals | Polymers | Refractory |

| Density | Low to High | Low to High | Low | Low to Medium |

| Hardness | High | Medium | low | Medium |

| Toughness | low | High | Medium | low |

| Wear Resistance | High | Medium | low | Medium |

| Tensile Strength | Low to Medium |

High | low | low |

| Compressive Strength | High | Medium to High | low to Medium | High |

| Young’s Modulus | Medium to High | Low to High | Low | Medium |

| Dimensional Stability | High | low to Medium | low | / |

| Thermal Expansion | Low to Medium | Medium to High | High | low |

| ThermalConductivity | Medium | Medium to High | Low | Medium |

| Thermal Shock | Low | Medium to High | High | low to Medium |

| Electrical Resistance | High | low | High | / |

| Chemical Resistance | High | low to Medium | Medium | / |

| Oxidation Resistance | Medium to High | low | low | / |

| Machinability | Medium | low | Medium | / |

| Product Name | Low Friction Zirconia Ceramic Valve Block Corrossion Resistant |

| Material | zirconia ceramic |

| Color | white or black or customed |

| Standard | according the request of customer |

| Grade | first class |

| Brade | Rock |

| Thread | coarse, fine |

| Use |

FAQ

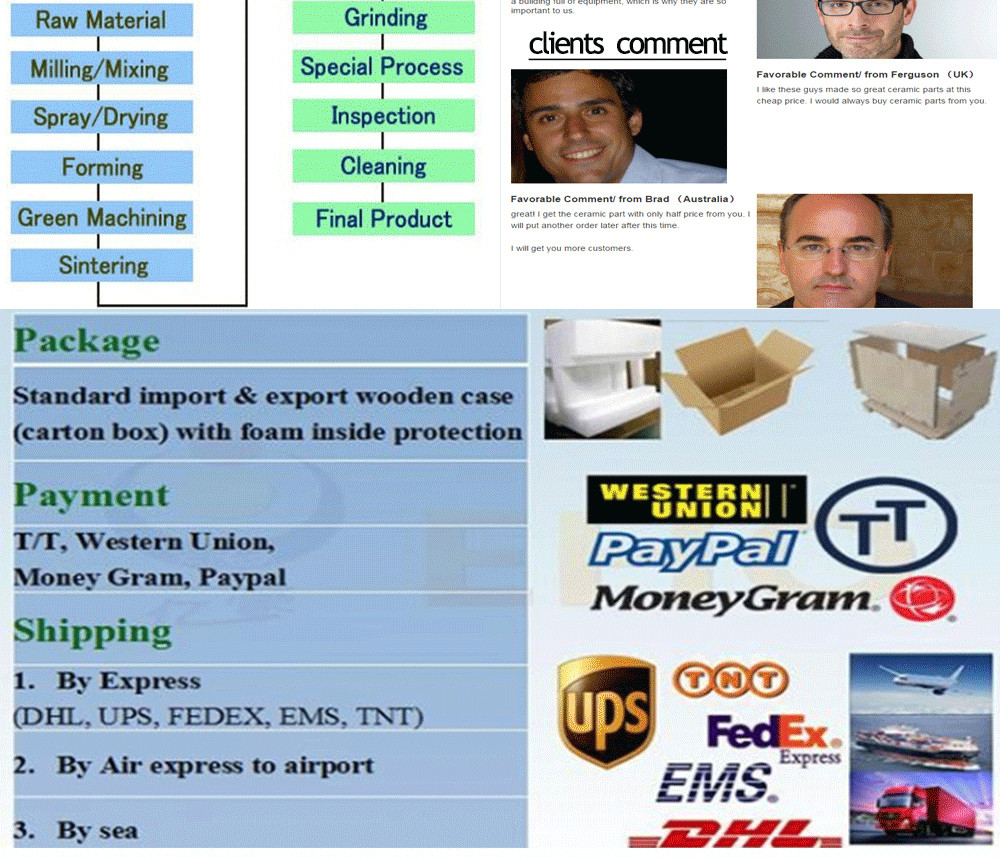

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

If you have any other question, pls feel free to contact us .

Zironia Ceramic Support