Active Member

|

[China]

Address: NO 21st ChuangXing Road, Shangsha community , Changan Town, Dongguan city Guangdong province, China

Contact name:Admin deng

Dongguan Ming Rui Ceramic Technology Co.,ltd |

|

High Hardness Black Ceramic Disc Black Zirconia Ceramic Washer for

Cutting

Black Ceramic Disc Black Zirconia Ceramic Washer

Material: zirconia ceramic washer

high Density: above 6.0 g/cm3

High strength and very hardness.

Long use time

Max Working temperature: <1100 degree

Vickers Hardness: 1300 HV0.5

Flexural Strength: 1000 Mpa

Color: White

Black Ceramic Disc Black zirconia ceramic washer provide excellent erosion, corrosion and abrasion resistance

along with temperature resistance, fracture toughness and strength.

These Black Ceramic Discs are used in extreme service applications that take advantage of

their superior wear and corrosion resistance.

Advantages of Black ceramic disc Zirconia ceramic washer

1. high precision

2. tight tolerance

3. customized design can be finished soon

1. High Thermal Expansion

2. Excellent Thermal Insulation; low thermal conductivity

3. High resistance to crack propagation,high fracture toughness

4. Ability to conduct oxygen ions

What Machines do you use for precision grinding?

Surface grinders

CNC milling machines

Jig grinders

Center less grinders

CNC lathes

ID grinders

Do you accept customized design?

Yes, most of our ceramic parts are customized from customers

What's the MOQ?

It depends on the design of ceramic parts. MOQ will be from 5 to

200 pcs.

Industrial Ceramic Intriduction

Zirconia are the most widely applied and cost effective technical

ceramic material. It offers a combination of superior mechanical

strength and electrical properties, wear resistance and corrosion

resistance. The maximum working temperature is up to 1700 °C with

relatively high thermal conductivity. It is also an electrically

insulating material with a high electrical resistivity. The good

corrosion resistance makes it insoluble in water and slightly

soluble in strong acid and alkaline solution.

Company Introduction

Mingrui ceramic manufacture and provides zirconia ceramic

disc for a wide range of application like Mechanical

Equipment, Electronic & Electrical, Oil Drilling, Medical,

Chemical Industry etc. According to actual application and

customer's requirement, the purities vary from 95%-99.7% and the

forming methods will be different. The forming methods applied in

our plant include dry pressing, isostatic pressing, injection

moulding, extrusion moulding. With experienced engineers and

talented workers, we are confident to offer high quality, high

precision, complex components for customers worldwide.

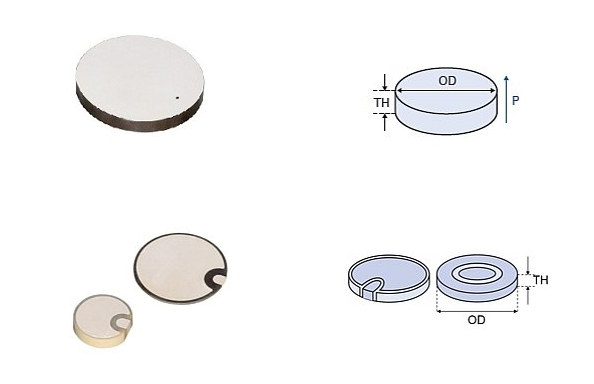

Porous ceramic Disc Description

Outer diameter OD |

|---|

| 0.1to 100 mm |

Thickness TH |

| 10 to 45 mm |

| General Characteristics of Materials: | ||||

| Characteristic | Ceramics | Metals | Polymers | Refractory |

| Density | Low to High | Low to High | Low | Low to Medium |

| Hardness | High | Medium | low | Medium |

| Toughness | low | High | Medium | low |

| Wear Resistance | High | Medium | low | Medium |

| Tensile Strength | Low to Medium | | low | low |

| Compressive Strength | High | Medium to High | low to Medium | High |

| Young’s Modulus | Medium to High | Low to High | Low | Medium |

| Dimensional Stability | High | low to Medium | low | / |

| Thermal Expansion | Low to Medium | Medium to High | High | low |

| ThermalConductivity | Medium | Medium to High | Low | Medium |

| Thermal Shock | Low | Medium to High | High | low to Medium |

| Electrical Resistance | High | low | High | / |

| Chemical Resistance | High | low to Medium | Medium | / |

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is

15-20 days if the goods are not in stock, it is according to

quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay

the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30%

T/T in advance ,balance before shippment.

If you have any other question, pls feel free to contact us .

Delivery:

Custom OEM will be shipped within 15 days after determining the

parameters

The samples will be shipped within 3 days

Quick Delivery Via Fedex,DHL,UPS,TNT Etc.

Support customer to designate shipping company

For more informations (the price,delivery time,moq etc)about the

ceramic plates, please contact us or email:admin@cerampart.com

CEO: Admin deng

Dongguan Mingrui Ceramic Tech. Co. Ltd.

Add: No.21 Chuangxing Rd., 2nd Industrial Zone of Shangsha,

Chang'an town, Dongguan city, Guangdong, China 523867

Email: admin@cerampart.com

FAQ

1. Monthly Capacity: 50,000-60,000 pcs;

2. Material: OEM or as per your suggestion;

3. Lead time: about 7-20 days, pls confirm the quantities required;

4. Incoterm: FOB, CFR, CIF;

5. Delivery Cost: It is determinated by the destination port;

6. Payment Term: PayPal; T/T; L/C.

7. Shipment: by sea, by air, by courier, by post, etc.