Active Member

|

[China]

Address: NO 21st ChuangXing Road, Shangsha community , Changan Town, Dongguan city Guangdong province, China

Contact name:Admin deng

Dongguan Ming Rui Ceramic Technology Co.,ltd |

|

Yttria Stabilized White Zirconia Ceramic Burner Plate Zirconium Oxide Ceramic Insulator Plates

Product Description

Zirconia Ceramic Plate, Wholesale Various High Quality Zirconia Ceramic Plate Products, they can work at the environment over 1000 Deg. C.

Produce and machining

We can produce different sizes and shapes of the sheets for specific applications to different custom products.Such as drilling, polishing, stripes, concave and convex, screw holes, metal parts position and so on

1. Can Be Custom By Drawing Or The Parameter

2.Can Be Offer a Samples Within 1--10 Qty

3. The Shipping Time Of The Samples Within 2days

4. Quick Delivery Via Fedex,Dhl,Ups,Tnt Etc.

For more informations (the price,payment etc), Please contact us or email: admin@cerampart.com

Materials:

· 95%--99.99% Alumina (Al2O3)

· Silicon Carbide

· Silicon Nitride

· TTZ: Magnesia partially stabilized Zirconia (ZrO2)

· YTZP: Yttria partially stabilized Zirconia (ZrO2)

· ZDY: Yttria fully stabilized Zirconia (ZrO2)

Properties Sheet:

| Properties | Units | 95 Alumina | 99 Alumina | Zirconia |

| Density | ɡ / cm3 | 3.65 | 3.92 | 5.95 - 6.0 |

| Water Absorption | % | 0 | 0 | 0 |

| Coefficient of Thermal Expansion | 10-6 / K | 7.9 | 8.5 | 10.5 |

| Modulus of Elasticity Young’s Mod | Gpa | 280 | 340 | 210 |

| Poisson’s Ratio | / | 0.21 | 0.22 | 0.3 |

| HV Hardness | Mpa | 1400 | 1650 | 1300 - 1365 |

| Flexural Strength @ Room Temperature | Mpa | 280 | 310 | 950 |

| Flexural Strength @ 700℃ | Mpa | 220 | 230 | 210 |

| Compressive Strength@Room Temperature | Mpa | 2000 | 2200 | 2000 |

| Fracture Toughness | Mpa * m½ | 3.8 | 4.2 | 10 |

| Heat Conductivity @ Room Temperature | W / m * k | 18 - 25 | 26 - 30 | 2.0 - 2.2 |

| Electrical Resistivity @ Room Temperature | Ω*mm2 / m | >1015 | >1016 | >1015 |

| Max Application Temperature | ℃ | 1500 | 1750 | 1050 |

| Resistance to Acid Alkaline | / | High | High | High |

| Dielectric Constant | / | 9.5 | 9.8 | 26 |

| Dielectric Strength | KV / mm | 16 | 22 | / |

| Thermal Shock Resistance | Δ T ( ℃ ) | 220 | 180 - 200 | 282 - 350 |

| Tensile Strength @ 25℃ | Mpa | 200 | 248 | 252 |

Advantages of high temperature ceramic plates:

1. Refractory.

2. Self Lubricating

3. Long Service Life.

4. Good Polished Surface.

5. Environmental and Healthy.

6. Superior Mechanical Strength.

7. High Corrosion and Wear Resistance.

8. Good Insulation Performance Precision.

9. High Temperature and Pressure Resistance.

10. High Purity Zirconia and Alumina Ceramic Material.

Due to these outstanding properties, Ceramic Products are used in a wide range of industrial and advanced appications.

And a lot of practical applications prove that our ceramic products has reached a state of high standard and quality.

Application

Ceramic block can be used for a device or equipment in the special

environment such as Power isolation, high temperature protection,

durable wear, high and low temperature impact etc...and for the

different device should be requiry different ceramic block shapes,

like: some device need the round sheet be machining 8 hole to

fasten to the box.

Detailed Images

Corrosion and Wear Resistance Zirconia Machinable Ceramic Porous Block in White Color

White Color Machinable Ceramic Block 95 - 99.7 % Alumina Circular Block / Disc

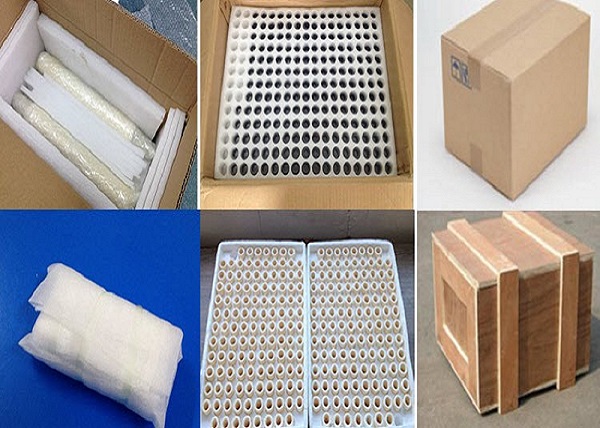

Packaging and Shipping

ZrO2 multihole ceramic plate will be wraped in paper first individually, then packed in bubble bags,

finally put in standard export carton packing, or OEM packing..

Shipped by Express ( DHL, TNT, UPS, Fedex, EMS ), Air, or

Sea transportation.

Company information

Who Are We?

Mingrui has years of professional OEM experience in manufacturing

industrial ceramic products. And very advanced technologies in the

production of zirconia and alumina ceramic rod, ceramic tube,

ceramic plate, ceramic ring, ceramic shaft, ceramic plunger,

ceramic valve, ceramic sleeve, ceramic nozzle, and semiconductor

ceramics, etc. They are applicable to Electrical, Appliance,

Mining, Oil & Gas, Energy & Power, Food & Medical,

Chemistry, Agriculture, Aerospace, even other high-end fields.

We, an advanced technical team with 10 senior engineers,more than 80 technicians and 100 equipment machines, taking one-stop production, from the raw material (powder) to final products, control the quality of every production link well.

In cooperation with Tsinghua University, we've achieved great successes in particular requirements. With our professional knowledge and business experience in machined ceramic parts, low-budget and high-performance new ceramic products are made of high–quality raw materials. The value of our ceramic products is greatly increased due to the composite technology and precise processing.

Our high efficiency machined ceramic parts, perfect service and

good reputation roots in our professional machined ceramic

technology, continuous innovation, great sincerity and our pursuit

for sustainable development. We have a unique technnology called

"mirror polishing" that has improved the brightness, color,

smoothness of our ceramic parts. Your advice and visit is our best

welcome!

Our products with some certificates, such as , CE, TUV, etc..

Factory Show

Production Process Show

We carry out one-stop production, from the raw material ( powder )

to final products, control the quality strickly of every

production link.