Zhengzhou Sanhui Refractory Metal Co., Ltd. |

|

Customized Arc Erosion Resistant Tungsten Copper Alloy

W80/Cu20 Polished tungsten copper is used for arcing contacts in SF6 circuit breakers for ultra high, high and medium voltage applications. At the heart of the switching chamber, WCu contacts are exposed to extreme mechanical and thermal loads: When the circuit is opened and closed, the arc starts directly at the switch contacts at a temperature of up to 20 000 °C.

Specification of Customized Arc Erosion Resistant Tungsten Copper Alloy:

| Product Name | Customized Arc Erosion Resistant Tungsten Copper Alloy |

| Material | Tungsten copper alloy |

| Surface | Polished |

| Dimensions | Customized |

| Application | Electrical Contacts |

W80/Cu20 Polished tungsten copper is popular because of its combination of unique material properties. Ahigh level of temperature resistance is one of the most important advantages of tungsten, while the copper content increases the electrical and thermal conductivity. Contact materials made of WCu are also characterized by the following properties:

|

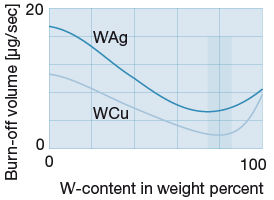

By choosing the right mixture of tungsten and copper, we are able to influence the product's arc erosion properties. At a tungsten content of 80 %, we achieve the lowest arc erosion rates. Depending on the voltage and current intensity as well as on economic considerations, we can vary the tungsten content between 60 and 90 % to meet the exact needs of your application. |

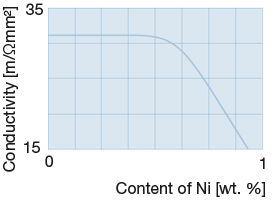

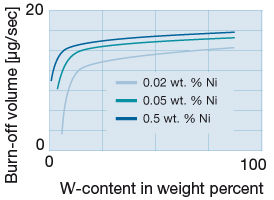

The denser the material, the better it is at conducting electricity and heat. One trick for producing WCu in higher densities is to add nickel during the sintering process. However, too much nickel has a negative influence on the conductivity of the material. Take advantage of our employees' experience and benefit from an optimum balance between material density and conductivity.

|  |

| FG20 | A20NiF | A20Ni | |

|  |  |

The higher the applied voltage is, the more resistant to arc erosion the contact material must be. SANHUI is able to modify the arc erosion resistance of WCu by varying the grain size of its tungsten. For particularly high voltage ranges, we use materials with an extremely fine grain size.