Wuxi Fenigal Science & Technology Co., Ltd. |

|

Verified Suppliers

|

|

Industrial Ro Water Machine Purification Water Purification Systems EDI module EDI MK-7

For many years, operators of pure water production systems were

trying to find a technology to replace mixed bed ion exchange for

final demineralization. The operating cost as well as the

complexity and risks associated with acid and caustic regeneration

were frustrations to these operators. EDI became established as the

innovative alternative solution by reducing operating costs,

improving site environmental, health, and safety risk profiles, and

producing a continuous and steady supply of pure and ultrapure

water.

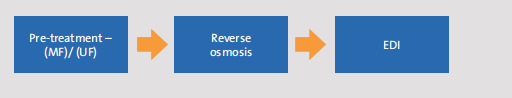

Production of pure water has evolved from conventional pretreatment

with multiple stages of ion exchange in initial and final

demineralization to the following membrane based

operations,including EDI, that are now considered to be best

practice by many customers around the world.

EDI utilizes both traditional ion exchange resin and ion exchange membrane to remove contaminants, including those that are uncharged or lightly charged in the feed water such as silica and boron. The biggest advantage lies in the fact that EDI technology employs direct current to drive contaminants out of the feed water and through the ion exchange membranes into the concentrate channels. The direct current also splits water into hydrogen and hydroxyl ions which act as continuous regenerating agents so that contaminants do not accumulate on the ion exchange resin. Therefore, EDI can continuously and predictably produce high-purity and ultrapure water with equal or better quality than mixed bed ion exchange.

MK-7 is designed to

• Provide ultrapure water for industrial applications including power and general industry.

• Produce mixed bed quality water on a continuous basis.

• Require no caustic or acid for regeneration of ion exchange resin within the stack.

• Be leak free, guaranteed.

• Eliminate brine injection and concentrate recirculation, simplifying system design.

description and use

MK-7 are high flow electrodeionization (EDI) stacks which use electrical current to deionize and polish reverse osmosis (RO) permeate water. MK-7 product water is at an ultrapure level required in today’s most demanding applications.

| Stack Specifications | ||

| Flow | 4.2 - 7.8 m3 /hr | 8 - 34 gpm |

| Maxmium flow | 7.8 m3 /hr | 34 gpm |

| Nominal flow | 6.0 m3 /hr | 26 gpm |

| Shipping weight | 137 kg | 300 lb |

Dimensions (width x length x height) | 31cm x 61cm x66cm | 12’’ x 24” x 26” |

| Typical Performance | ||

| Product Quality | ||

| Resistivity | > 16 MOhm-cm | |

| Sodium | < 3 ppb | |

| Silica (SiO2) Removal | Up to 99% / < 5 ppb | |

| Boron Removal | > 95% | |

| Operation Parameters | ||

| Recovery | Up to 97% | |

| Concentrate Flow (vs. Product Flow) | Countercurrent, hardness ≥0.10 ppm as CaCO3 Cocurrent, hardness | |

| Voltage | 0 - 400 VDC | |

| Amperage | 0 - 5.2 ADC | |

| Inlet Pressure Cocurrent | 3.1 - 6.9 bar | 45 - 100 psi |

| Inlet Pressure Countercurr | 4.1 - 6.9 bar | 60 - 100 psi |

| Pressure Drop | .0 - 3.8 bar | 15 - 55 psi |

| Maximum Feed Water Specifications | ||

| Feed Water - Total Exchangeable Anions (TEA as CaCO3) | < 25 mg/l | < 25 ppm |

| Feed Water – Conductivity, NaHCO3 equivalent | < 43 μS/cm | < 43 μS/cm |

| Temperature | 5 - 40˚C | 41 - 104˚F |

| Total Hardness (as CaCO3) | < 1.0 mg/l | < 1.0 ppm |

| Silica (SiO2) | < 1.0 mg/l | < 1.0 ppm |

| Total Organic Carbon (TOC as C) | < 0.5 mg/l | < 0.5 ppm |

| Total Chlorine | < 0.05 mg/l | < 0.05 ppm |