Phoenix (suzhou) electronic Co.,ltd |

|

Application Introduction:

The bulb uses LED as the light source, and there is no IR (infrared) component in the spectrum when the LED emits light, and the overall structure adopts a professionally designed heat dissipation structure. The temperature during normal operation is only 40-60 ℃. Even if it is widely used, it is far lower than that produced by ordinary bulbs and energy-saving lamps. If it is in summer, it will significantly reduce the workload and time of refrigeration equipment, combined with the difference in power (1:10), As a result, the relative reduction of power consumption saves expenses, and finally reflects the energy saving of the bulb.

2835 6v 2w SMD LED chip 6000-6500k 280lm/w for bulb lamp

Quick details:

| Input Voltage(V): | 6V |

| Warranty(Year): | 2-Year |

| Type: | Smd Led Chip 2835 |

| Lighting solutions service: | Lighting and circuitry design |

| Luminous Efficacy(lm/w): | 280lm/w |

| Lifespan (hours): | 50000 |

| Working Time (hours): | 20000 |

| Chip Material: | INGAN |

| Emitting Color: | 10000-15000k |

| Power: | 1w |

| Viewing Angle(°): | 120 Degree |

| Color Rendering Index(Ra): | 80 |

| Packing bag: | 220*240nm |

| Place of Origin: | Suzhou ,jiangsu |

| Application: | LED STRIP |

| Package Type: | Suface Mount Package |

| Forward Current: | 300MA |

| Size: | 2.8*3.5*0.65mm |

| Packing: | 4000 Pcs/Roll |

Product specification:

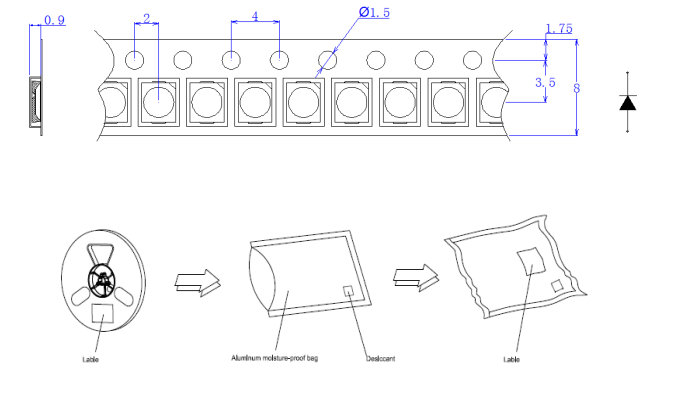

Package Structure

Absolute Maximum Ratings

| Item | Symbol | Absolute Maximum Ratings | Unit |

| Forward Current | IF | 300 | mA |

| Reverse Voltage | Vr | 7 | V |

| Pulsed Forward Current | IFP* | 400 | mA |

| Power dissipation | PD | 1 | W |

| Operating Temperature | TOP | -40~85 | ℃ |

| Storage Temperature | TST | -40~85 | ℃ |

| Electrostatic Discharge | ESD | 2000(HBM) | V |

| Junction Temperature | Tj | 120 | ℃ |

| LED Thermal resistance | Rth s-j | 30 | ℃/W |

Typical Electro-Optical characteristics curves:

LED Reliability Test List

| Test Item | Test Conditions | Standard | Qty(Pcs) | Ac/Re |

| Life Test | 25℃,1000Hrs@300mA | / | 22 | 0/1 |

| High Temperature | 85℃,1000Hrs@300mA | / | 22 | 0/1 |

| Low Temperature | -40℃,1000Hrs@00mA | / | 22 | 0/1 |

| High Humidity Heat | 85℃,85%RH, 1000Hrs@300mA | / | 22 | 0/1 |

| Low Temperature Storage | -40℃,1000Hrs | JEITA ED-4701 200 202 | 22 | 0/1 |

| High Temperature Storage | 100℃,1000Hrs | JEITA ED-4701 200 201 | 22 | 0/1 |

| Temperature Cycle | (-40'C 30mins --25'C(5mins)--100'C(30mins) ,Temp changing rate:3+/-0.6'C/min) | JEITA ED-4701 100 105 | 22 | 0/1 |

| Thermal Shock | -40'C(15mins) --100'C(15mins),changing time <5mins ,300C | MIL-STD-202G | 22 | 0/1 |

Pulse Life Test

| Tp=1ms,DC=0.1,D=Tp/T @ 3×300mA | / | 22 | 0/1 |

| ESD Test(HBM) | 2000V,200V/Step, Forward & Reverse Test both 3times | AEC (Q101-001) | 22 | 0/1 |

| Soldering Resistance | 260±5℃,10S,3times Pre-treatment 30℃,70%RH | JEITA ED-4701 300 302 | 22 | 0/1 |

| Reflow IV Decay | 260±5℃,10S,1time Pre-treatment 30℃,70%RH,168Hrs | / | 22 | 0/1 |

| Judgment Criteria | ||||

| Forward Voltage VF | VF Max-Increase < 1.1x | |||

| Reverse Current IR | IR Max-Increase < IRmax | |||

| Luminous Intensity IV | IV Decay < 40% | |||

※Solder ability test criteria:coverage is not less than 95% Note:Measurement shall be taken after the tested samples have been returned to normal ambient conditions (generally after two hours) | ||||

Packaging:

Cautions:

The encapsulated material of the LEDs is silicone. Therefore the LEDs have a soft surface on the

Top of package. The pressure to the top surface will be influence to the reliability of the LEDs. Precautions Should be taken to avoid the strong pressure on the encapsulated part. So when use the picking up nozzle,The pressure on the silicone resin should be proper.

Soldering iron :

When hand soldering, the temperature of the iron must less

than 300℃ for 3 seconds

The hand solder should be done only one times

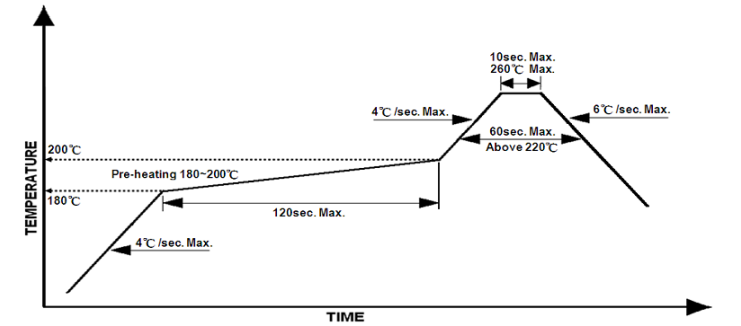

SMT Reflow Soldering Instructions SMT :

Reflow soldering should not be done more than two times

When soldering , do not put stress on the LEDs during heating

The recommended reflow soldering profile as following

Handling Precautions :

Handle the component along the side surface by using forceps or

appropriate tools

Do not directly touch or handle the silicone lens surface. It may

damage the internal circuitry

Do not stack together assembled PCBs containing LEDs. Impact may

scratch the silicone lens or damage the internal circuitry

Product features:

Adopt good quality chip and frame ,antistatic good stability Ultra low attenuation

High brightness ,low attenuation high color rendering

Minimum 70,80,90 95 CRI options

Strong welding and good stability undead light

Product series and company logo on the front

CE ROHS LM80 Certification

Production Process: